Dynamic synchronous lifting device for lifting platform

A lifting platform and synchronous lifting technology, applied in the direction of parking buildings, building types, buildings, etc., can solve the problems of unreasonable structure and force design, inconvenient work and maintenance, and reduced work efficiency, so as to improve safety. And the effect of stability, reliability and safety, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

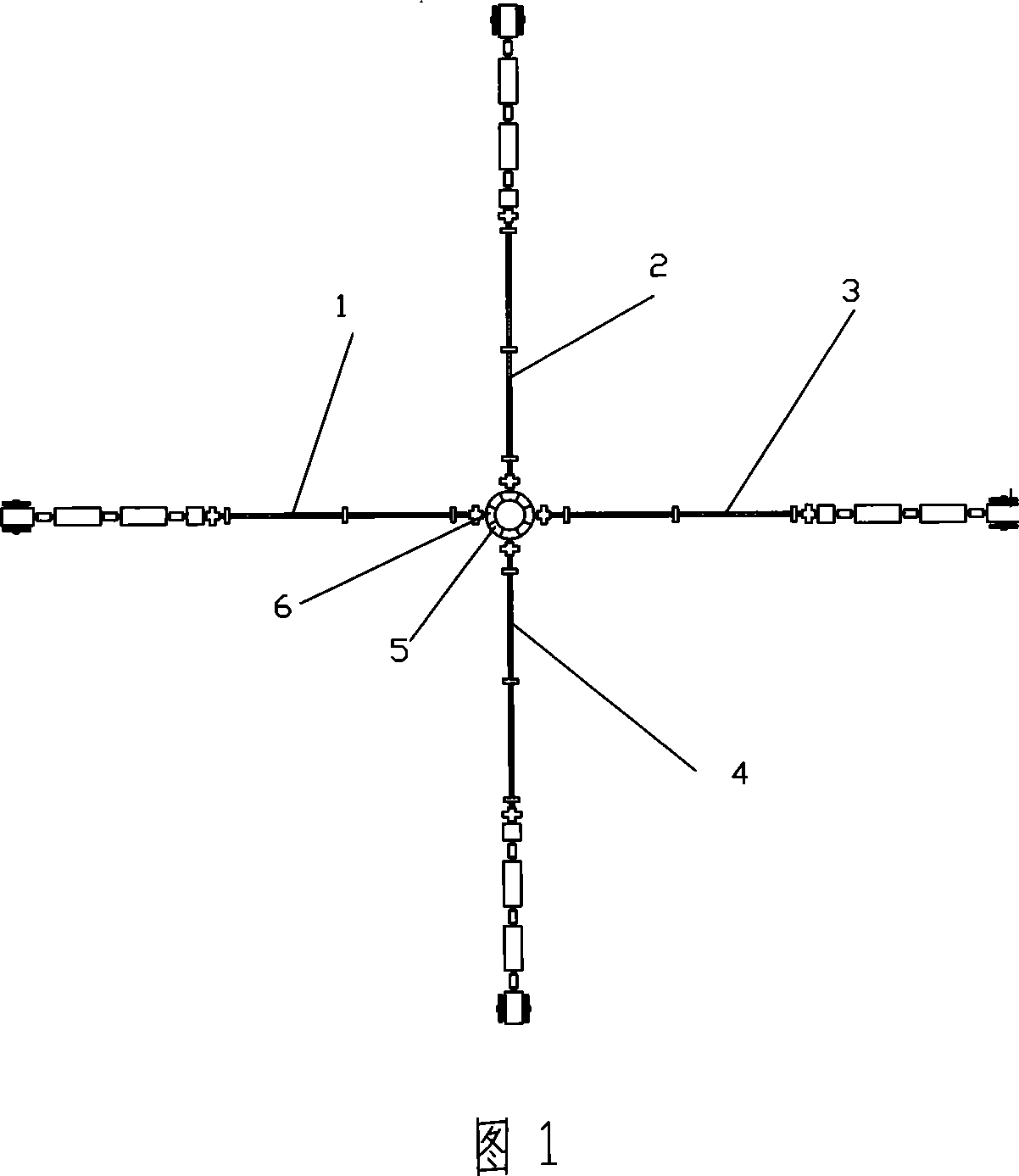

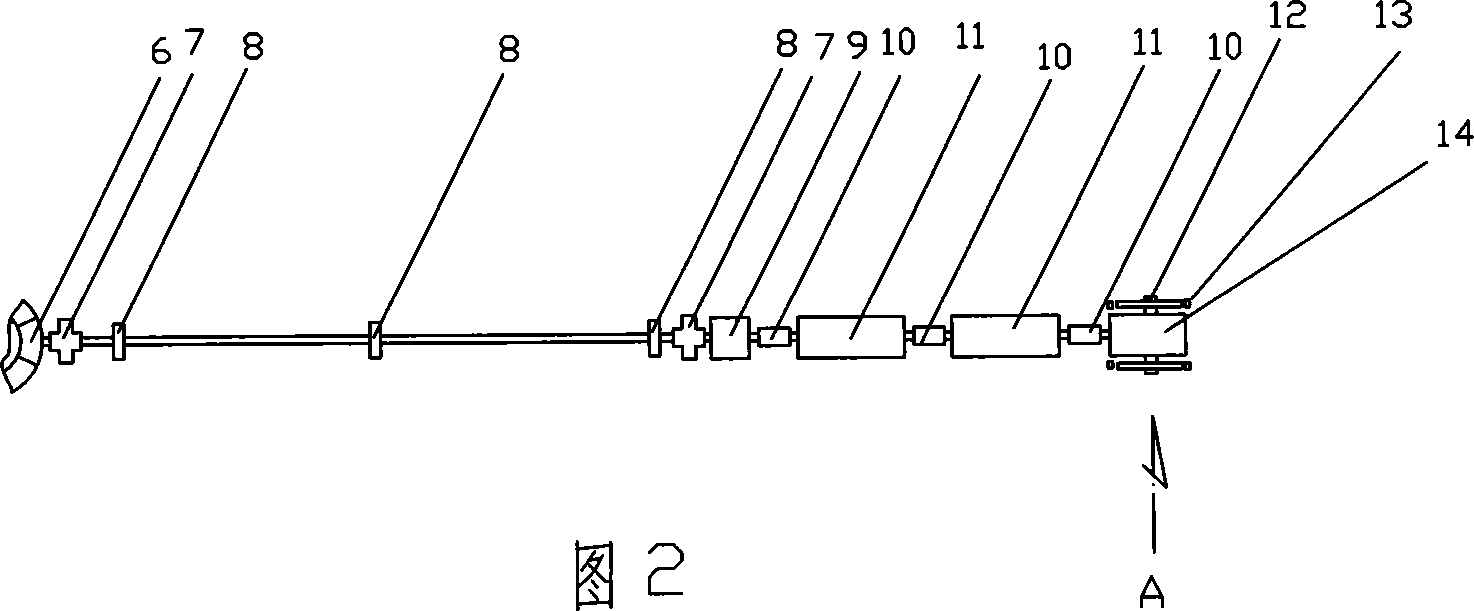

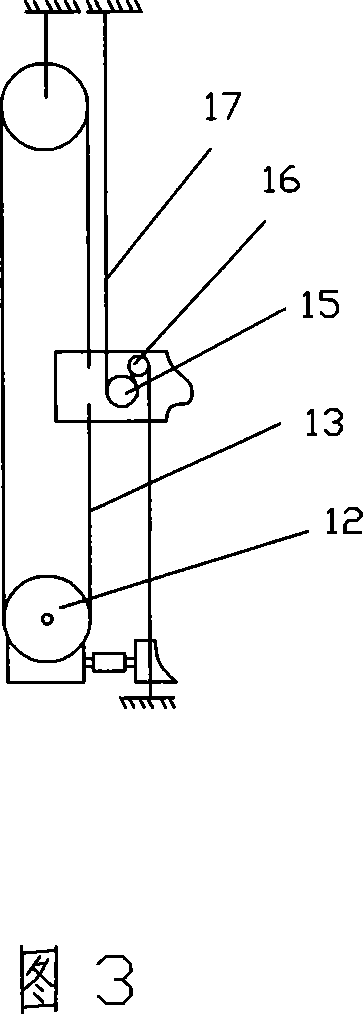

[0020] Referring to Figures 1 to 7, a power synchronous lifting device for an automobile lifting platform has four drive shafts 1, 2, 3, and 4, and each drive shaft 1, 2, 3, and 4 is equipped with two motors 11 , all are brake motors, and the reducer 9 is a cycloidal pinwheel reducer (with a large reduction ratio), equipped with a bearing seat 8, a shaft coupling 10, and a universal joint 7, and all transmission shafts 1, 2, 3 The output ends of the cycloid reducer 9 of , 4 are all connected with the synchronous mechanism, the structure of this synchronous mechanism: each transmission shaft 1, 2, 3, 4 ends are all connected with a small bevel gear 6, all small bevel gears 6 are Mesh with the same large bevel gear 5. The other ends of all transmission shafts 1, 2, 3, 4 are connected with chain 13 by speed reducer 1 (worm gear reducer) and sprocket wheel 12, and worm screw and transmission shaft are coaxial, and worm gear and sprocket wheel 17 are coaxial. And be provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com