Light guide plate, light guide unit arrangement structure and surface light source

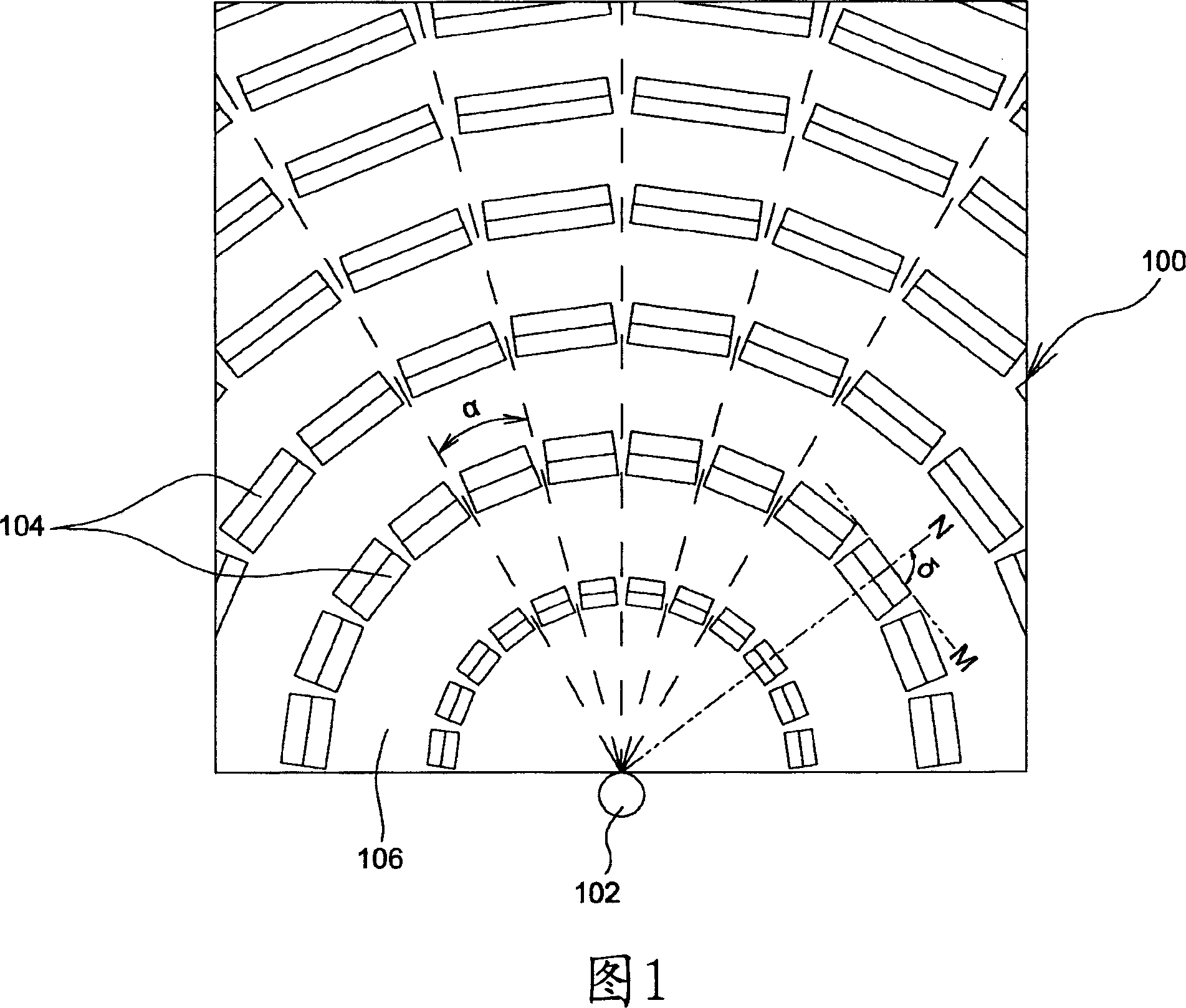

A technology of light guide unit and light guide plate, applied in the directions of optical elements, light guides, optics, etc., can solve the problems of affecting visual effects, brightness uniformity limitation, and high density of light guide units 104, avoiding moire and dark lines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

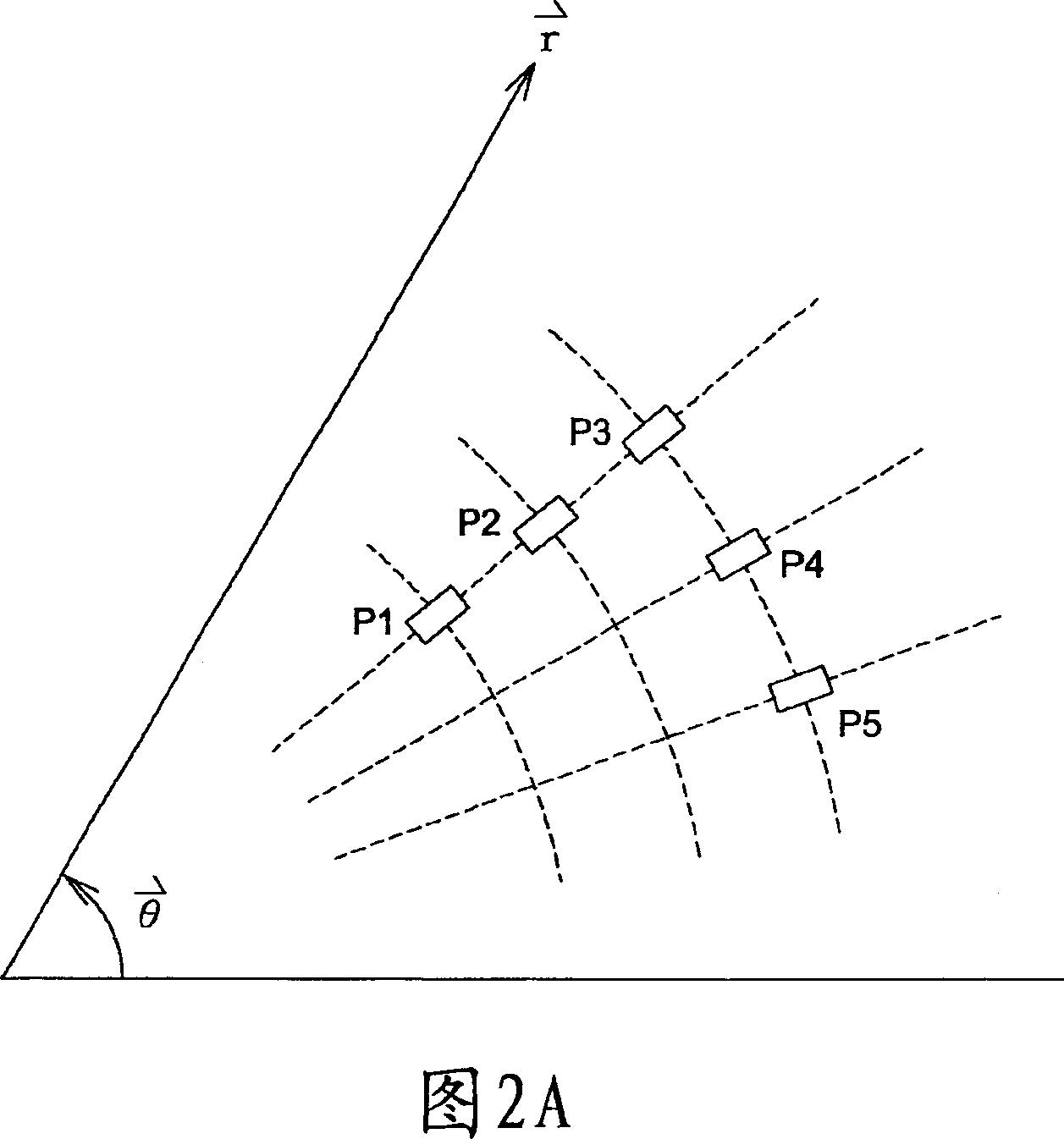

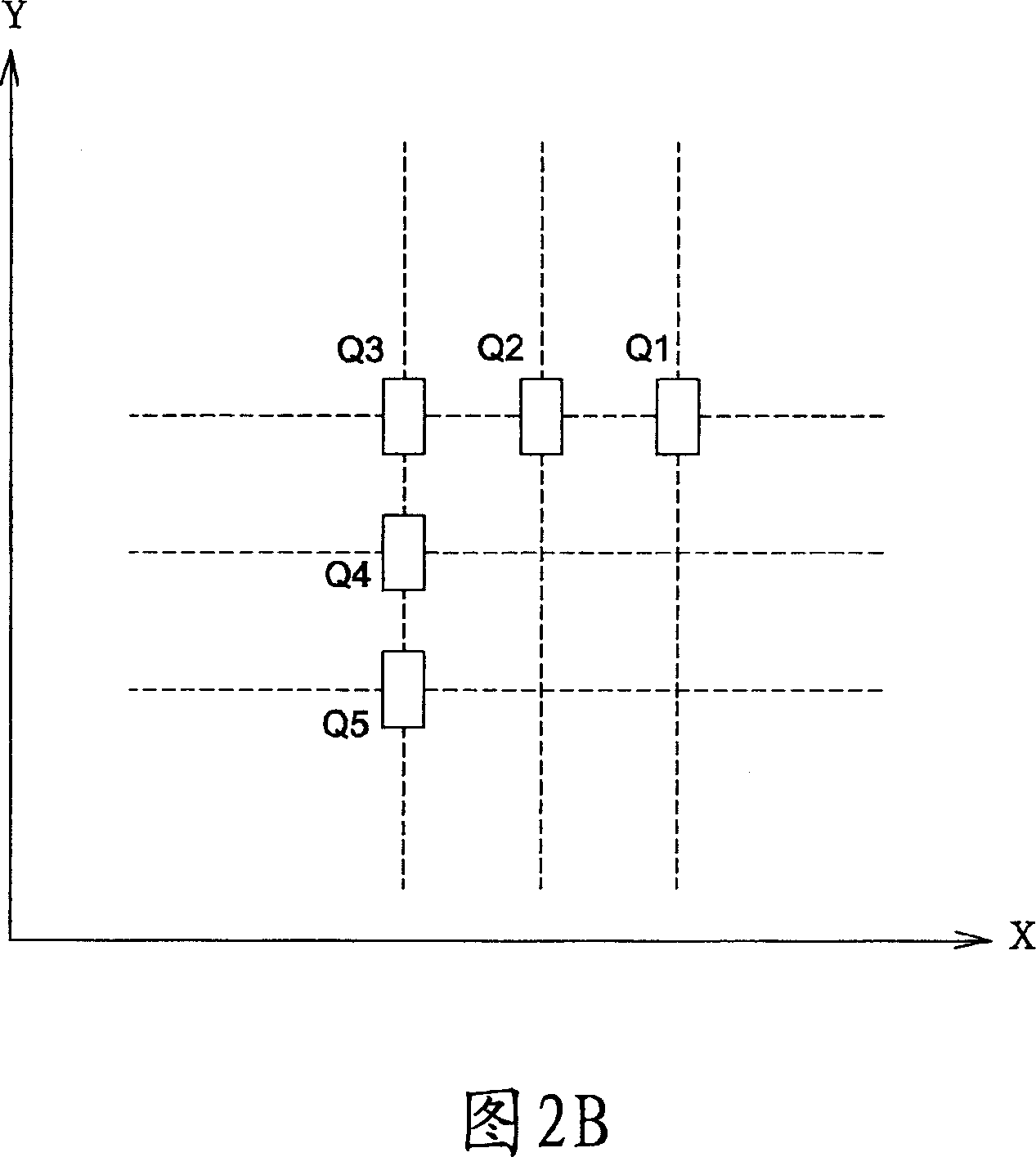

[0036] Before explaining the design of the present invention, the arrangement rules of the light guide units on the plane are clearly defined as follows.

[0037] As shown in FIG. 2A, when the light guide units are distributed on a polar coordinate (polar coordinate) plane, if the light guide units P1, P2, and P3 are substantially arranged in a straight line, it is defined as being arranged along the r direction of the polar coordinates, and as shown in The light guide units P3 , P4 , P5 are arranged on the same concentric circle relative to the origin, and are defined as being arranged along the θ direction of polar coordinates as the angle θ changes. On the other hand, as shown in FIG. 2B, if the light guide units are distributed on a Cartesian coordinate plane, the light guide units Q1, Q2, and Q3 are substantially arranged in a straight line, which is defined as being arranged along the X-axis direction of the Cartesian coordinates. , the light guide units Q3 , Q4 , Q5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com