Spark plug

一种火花塞、火花的技术,应用在火花塞领域,能够解决火花扩散速度和燃烧效率降低、不能除去、扩大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

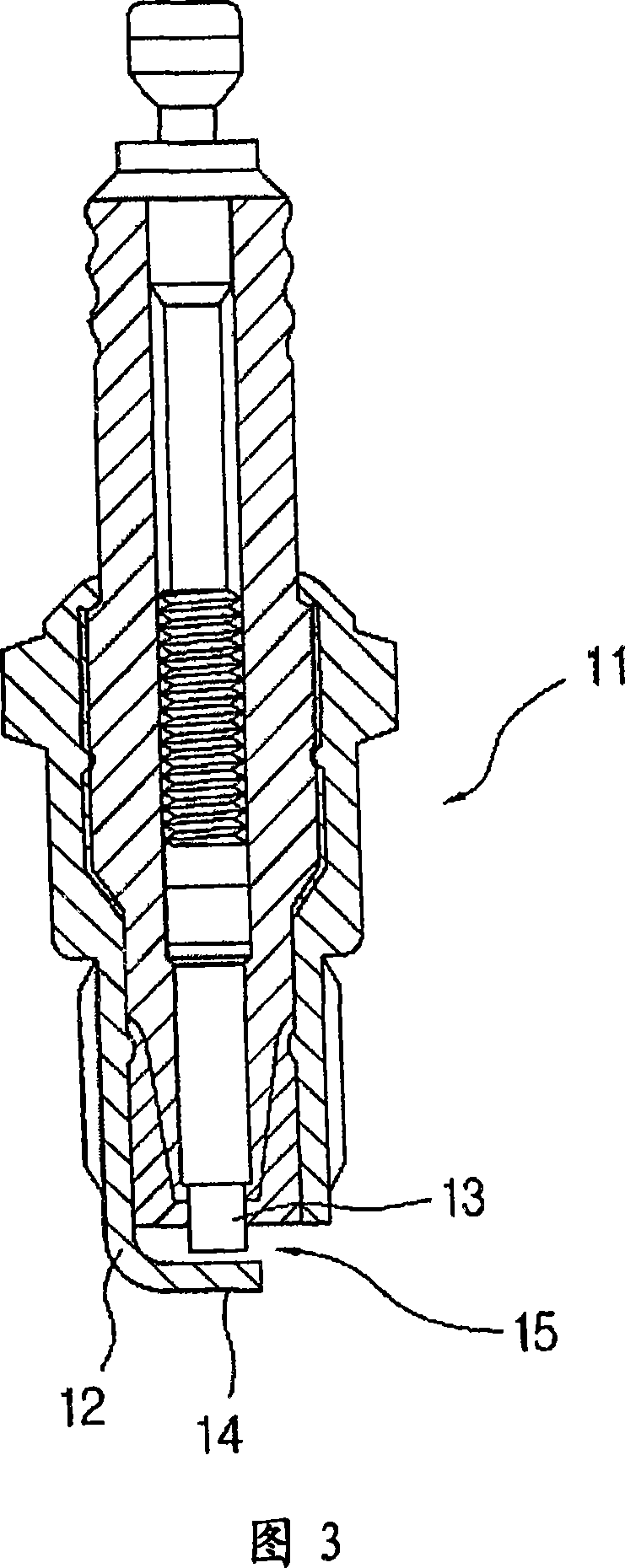

[0017] [17] The configuration of the present invention will be described below with reference to the drawings.

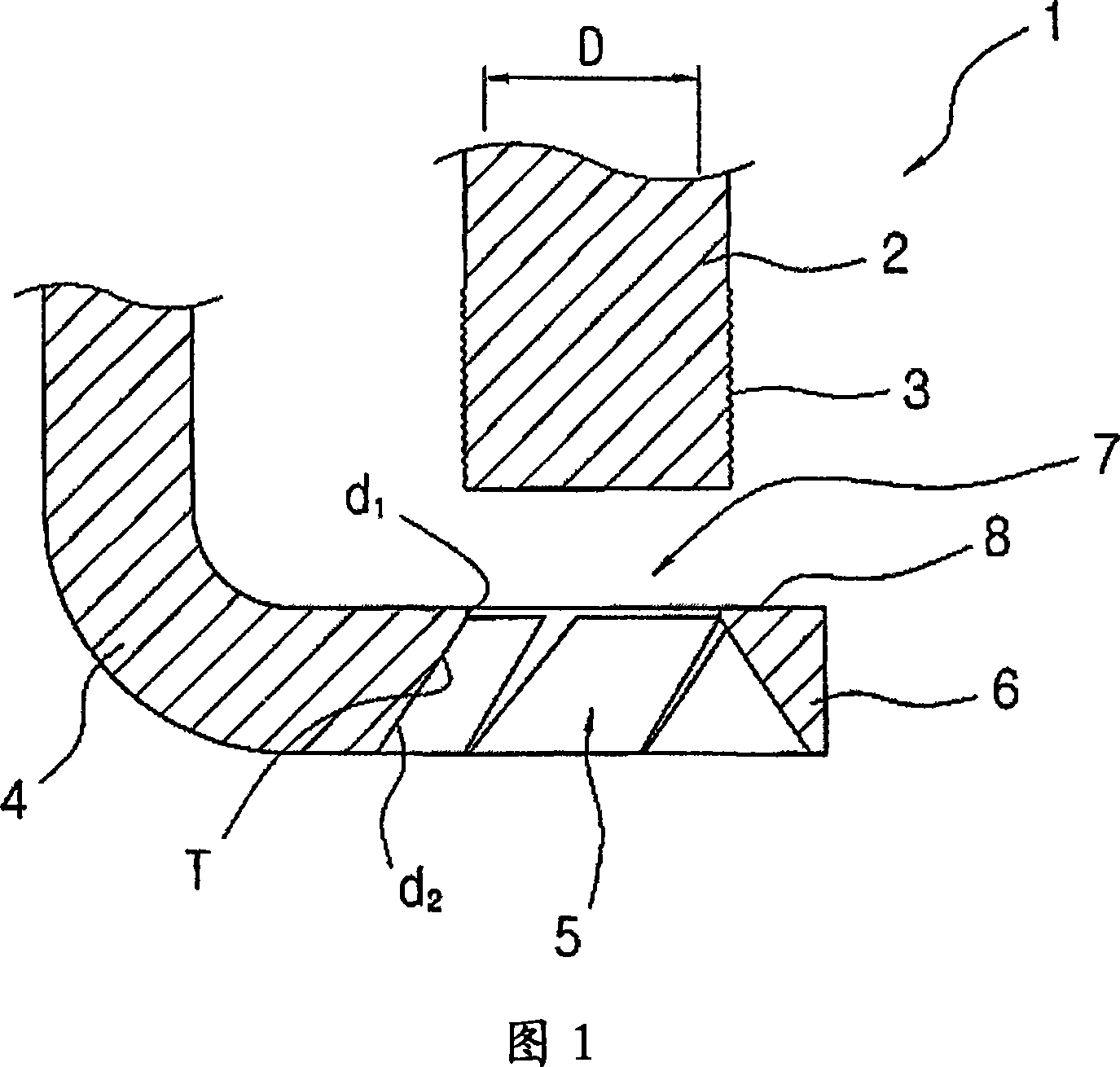

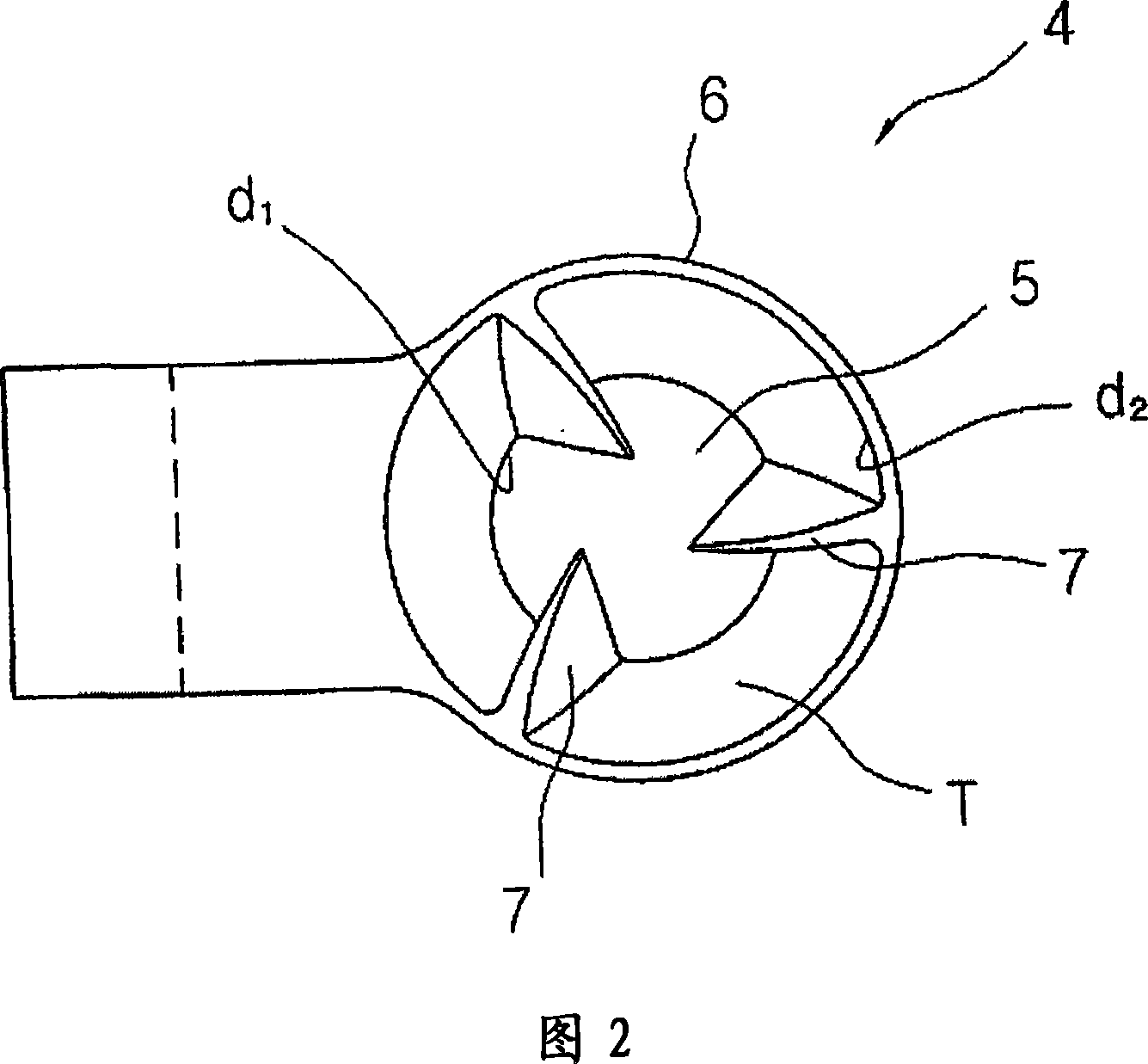

[0018] [18] FIG. 1 is an enlarged front cross-sectional view illustrating an electrode of a spark plug according to the present invention, and FIG. 2 is a bottom view illustrating a side ground electrode of the spark plug according to the present invention.

[0019] [19] When describing the present invention, please refer to the traditional technology for the same elements (except electrodes) as those of the conventional technology.

[0020] [20] Protrusions 3 are formed on the lower surface of the shaft core electrode 2 of the spark plug 1, like a structure in which small sand grains protrude through a knurl cutting process, so as to enhance the discharge effect. The discharge end of the side ground electrode installed on the lower side of the shaft core electrode 2 forms a circular portion 6 which includes a central circular hole 5, like surrounding a space, inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com