Multifunctional top-gun of together using channel for RH vacuum firing furnace

A multi-functional, vacuum furnace technology, applied in burners for burning powder fuels, transportation of non-flammable liquids/gases, combustion methods, etc. functionality, reduced manufacturing and operating costs, and improved interior space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

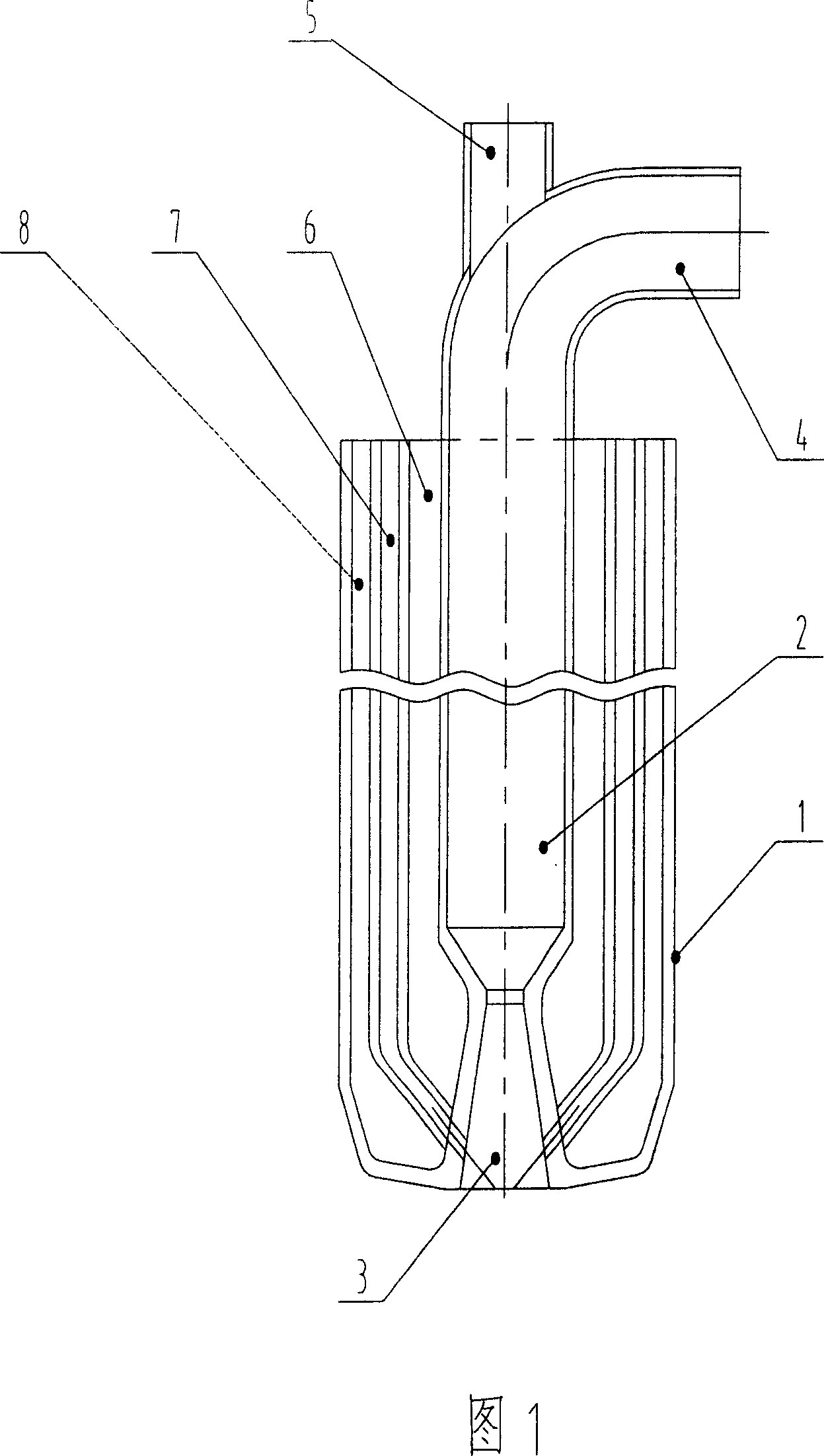

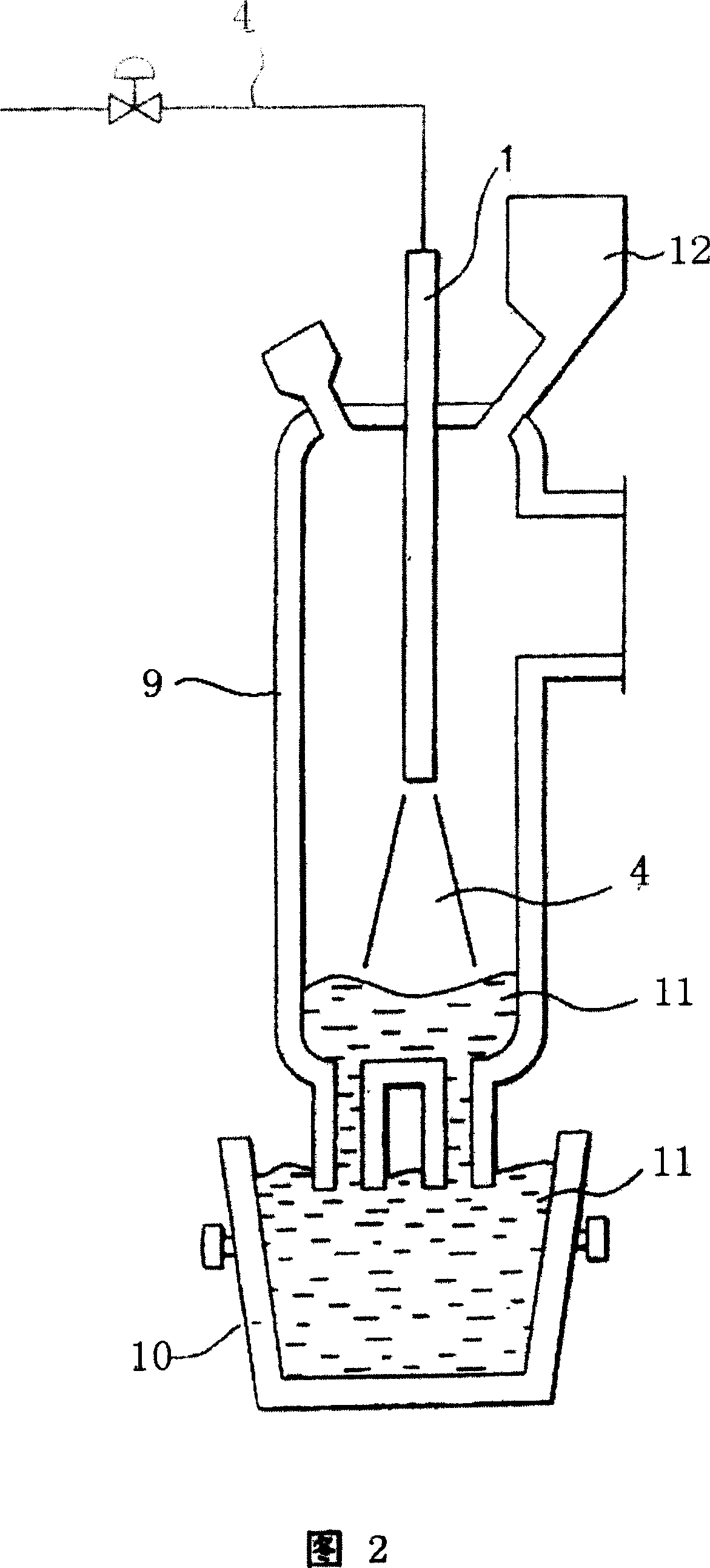

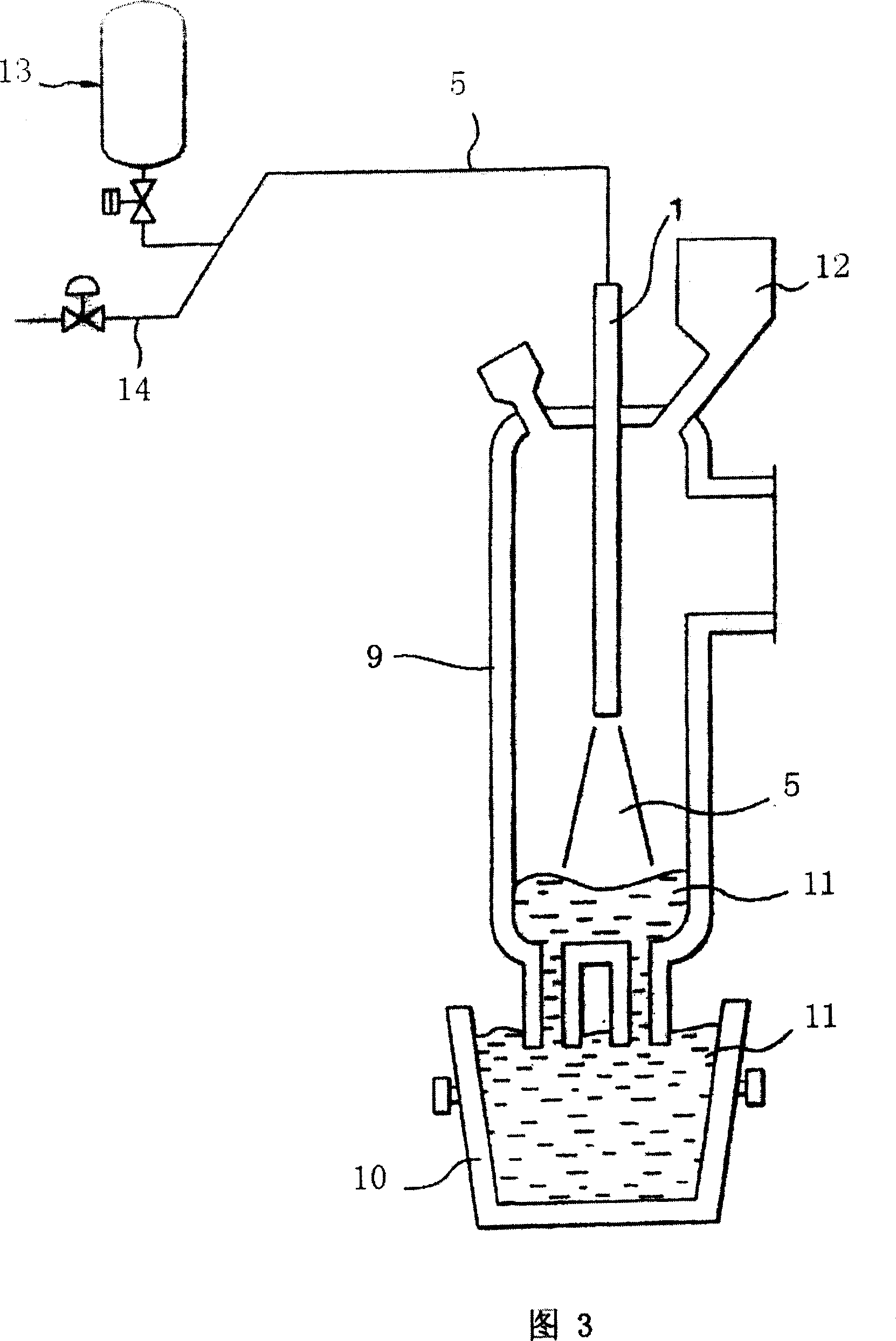

[0016] The embodiment is to design the channels and nozzles for blowing oxygen and powder to molten steel as the same channel and nozzles, and place them on the axis line of the top gun. The outlet of the gas channel is arranged near the outlet end of the above-mentioned nozzle, so that the gun body is only a four-layer casing when it has the three functions of oxygen blowing, powder spraying and baking. The innermost layer is the oxygen blowing and powder spraying channels and nozzles, the second inner layer is the cooling water inlet channel, the outer layer is the gas channel, and the outermost layer is the cooling water outlet channel. The cooling water inlet channel and the gas channel can be designed interchangeably, but the sub-inner layer is set as a cooling water inlet pipe channel to have a better cooling effect on each channel in the cooling gun body.

[0017] The multi-functional top gun with shared channel for RH vacuum furnace of the present invention is a four-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com