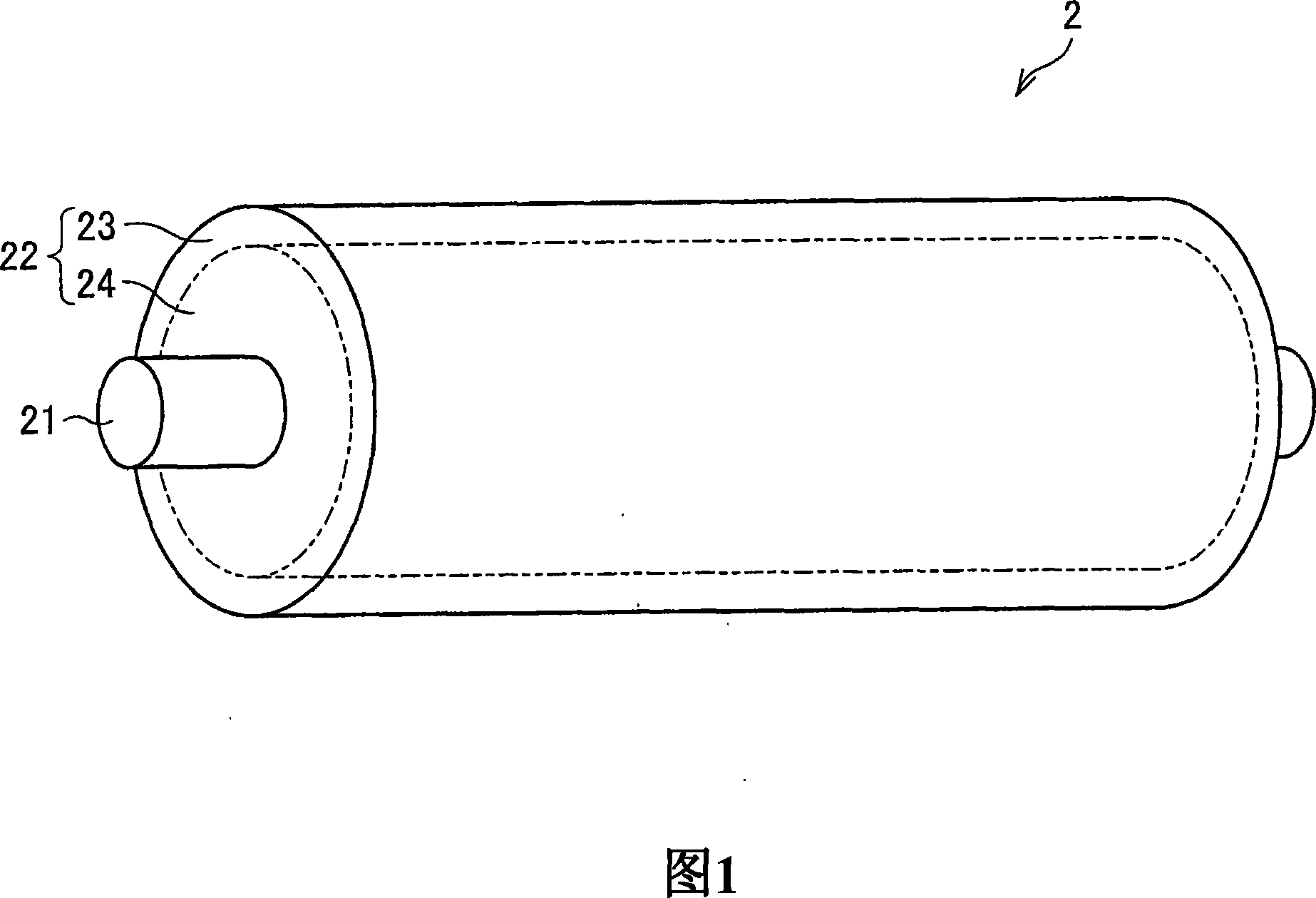

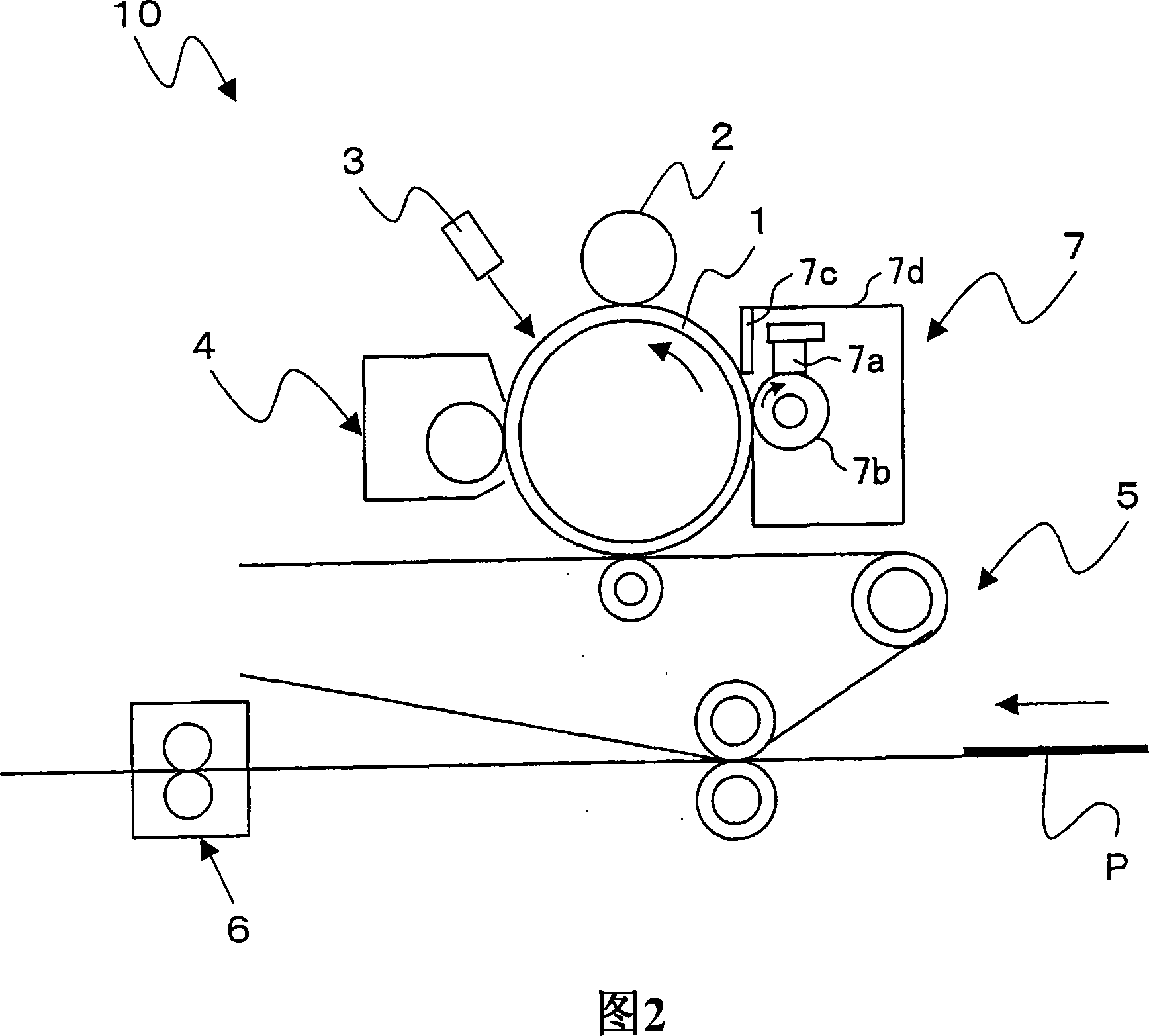

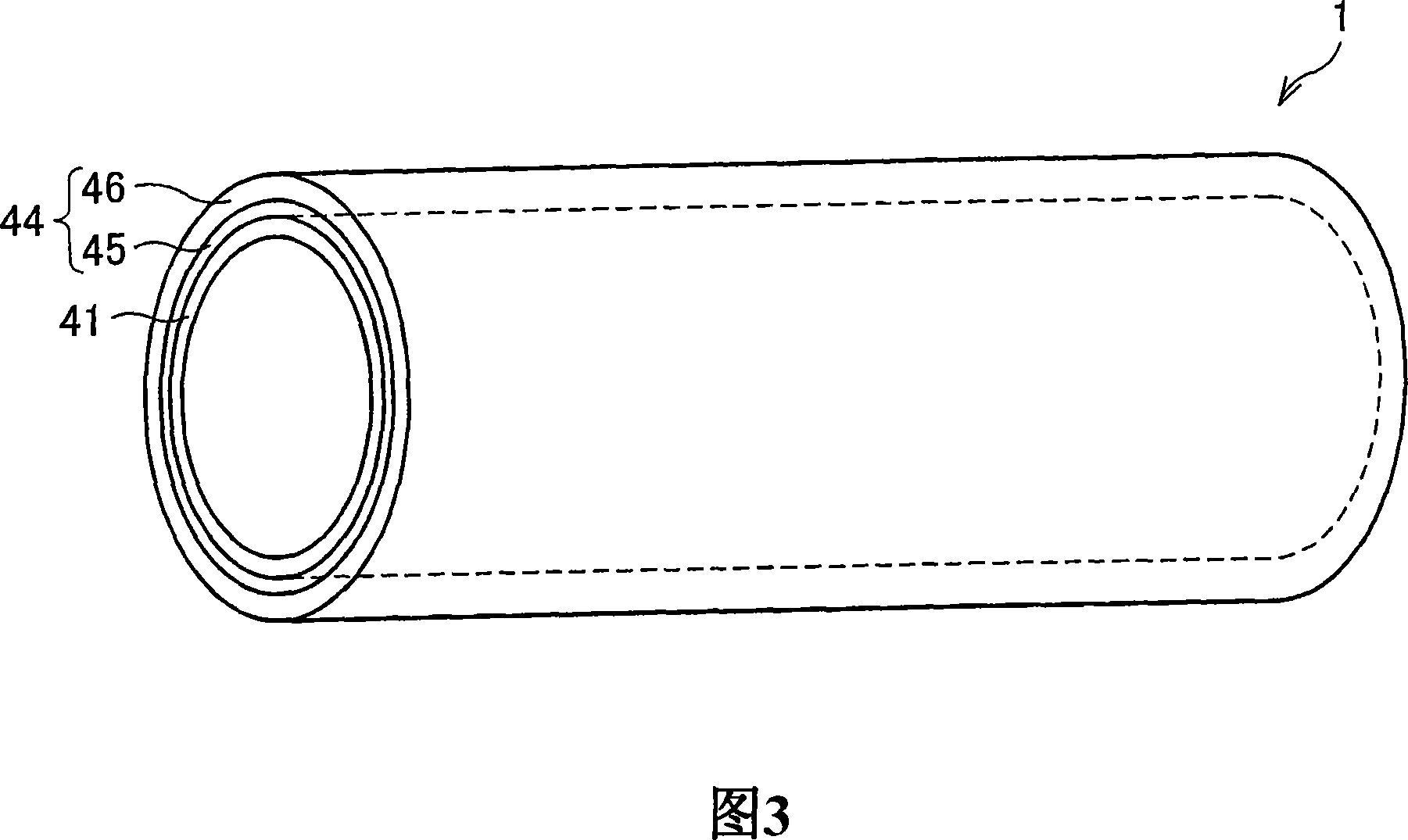

Charging roller, process cartridge and image forming apparatus

A charging roller and image carrier technology, which can be used in corona discharge devices, electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, etc., and can solve the problems of ion conductive agent leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0110] The calcination temperature in the above-mentioned calcination process was set to "high" among three steps consisting of "high", "standard", and "low". The firing time was set to "long" among three steps consisting of "long", "standard" and "short". The concentration of the surface treatment liquid was set to "high" among three steps consisting of "high", "standard", and "low".

[0111] The charging roller 2 surface-treated under the above-mentioned conditions was brought into contact with the photoreceptor 1 coated with lubricant and stored for a long period of time. As a result, image defects due to contamination of the photoreceptor were not found from the first sheet. Also, the coefficient of dynamic friction between the charging roller 2 and the photoreceptor 1 is 0.25.

[0112] However, after the charging roller 2 was assembled into the modified equipment for printing, black streak-like image defects were obviously found. This is considered to be because the sli...

Embodiment 1-2

[0114] The firing temperature was set to "high", the firing time was set to "long", and the concentration of the surface treatment liquid was set to "high".

[0115] The charging roller 2 surface-treated under the above conditions was brought into contact with the photoreceptor 1 not coated with lubricant and stored for a long period of time. As a result, image defects due to contamination of the photoreceptor were not found from the first sheet. Also, the coefficient of dynamic friction between the charging roller 2 and the photoreceptor 1 is 0.25.

[0116]However, after printing with the charging roller 2 , a small amount of image defects in the form of black streaks were found. It is considered that this is because the charging roller 2 slightly slipped.

Embodiment 1-3

[0118] The calcination temperature was set as "high", the calcination time was set as "long", and the concentration of the surface treatment liquid was set as "standard".

[0119] The charging roller 2 surface-treated under the above-mentioned conditions was brought into contact with the photoreceptor 1 not coated with lubricant and stored for a long period of time. As a result, image defects due to contamination of the photoreceptor were not found from the first sheet. Also, the coefficient of dynamic friction between the charging roller 2 and the photoreceptor 1 was 0.27. Further, even after printing was performed with this charging roller 2 , no image defect due to slipping of the charging roller 2 was found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com