Container closure assembly with internal neck thread

A technology for assemblies and containers, applied in the direction of threaded closures, closures with auxiliary devices, closures with auxiliary devices, etc., can solve the problems of consumption, laborious rotation of closures, and failure to completely replace glass bottles, etc. achieve an easy-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

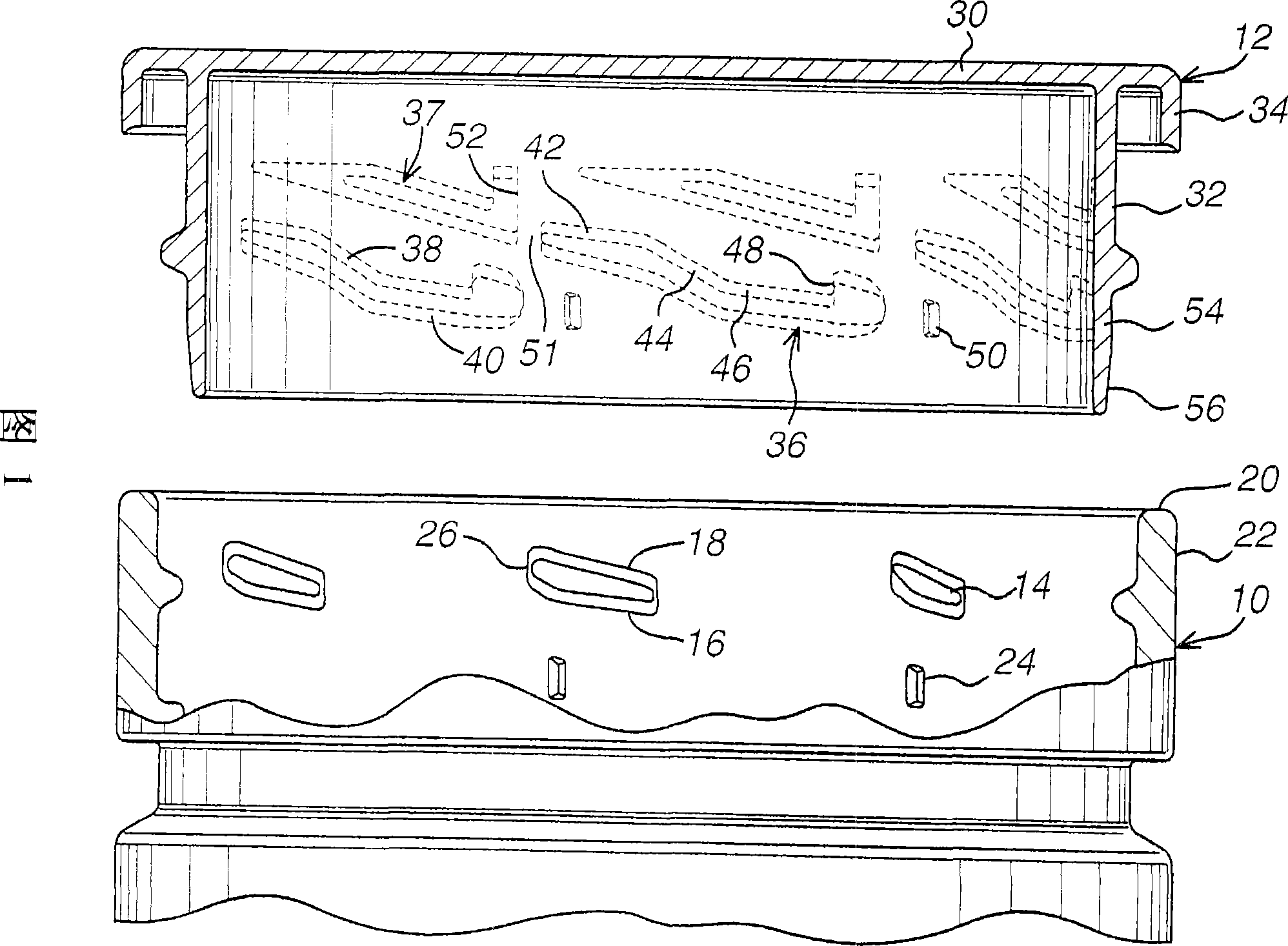

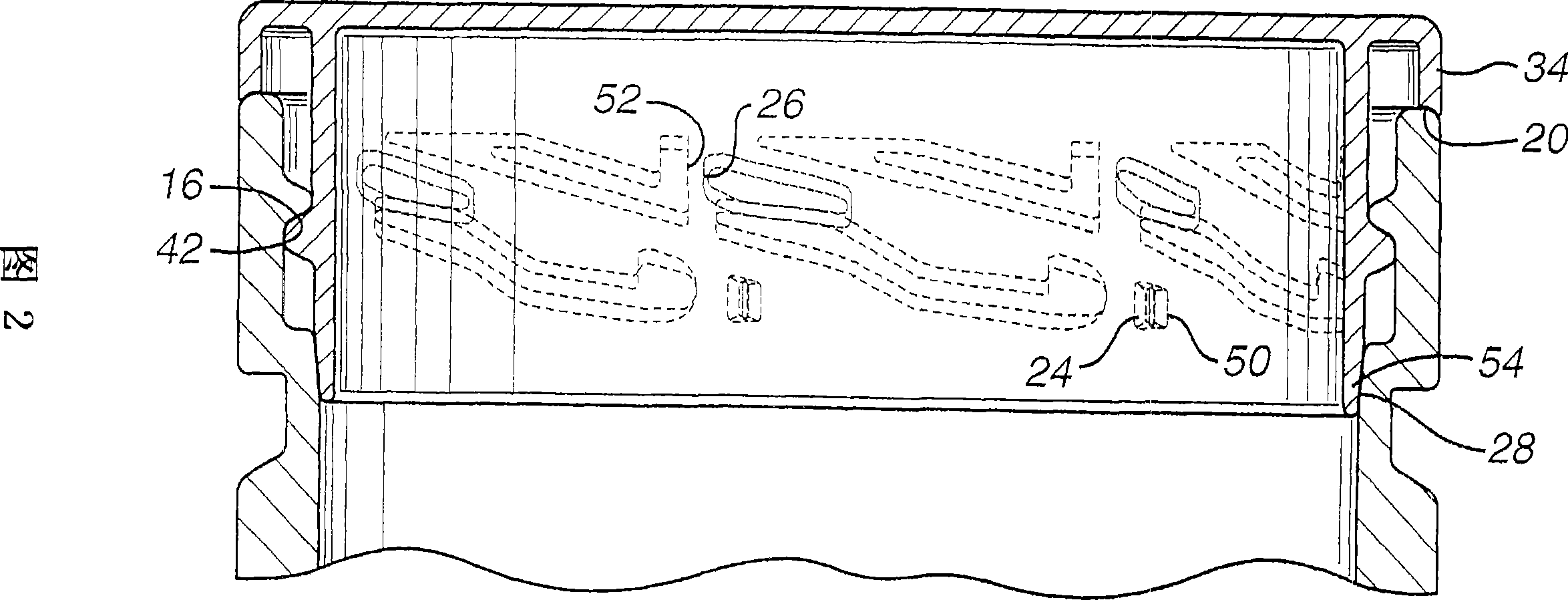

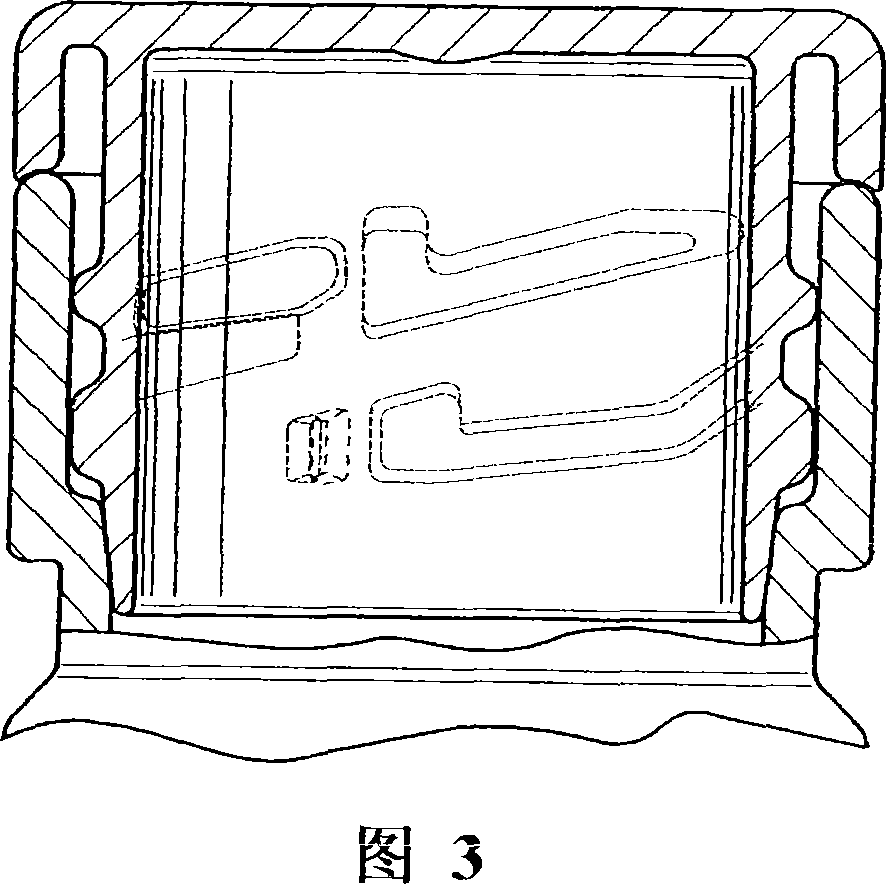

[0069] Please refer to FIG. 1 and FIG. 2 , this embodiment is a container closure assembly, especially suitable for wide-mouthed containers such as drinking vessels. The assembly includes a container neck 10 and a closure 12 on the carbonated beverage container; the container neck 10 and the closure 12 are all made of plastic materials, preferably, the container neck 10 is made of polyethylene terephthalate It is formed by injection molding or blow molding of ester, and the cover 12 is formed by injection molding of polypropylene.

[0070]Threaded features on container necks and closures and similar components are described and claimed in International Patent Applications WO95 / 05322, WO97 / 21602, WO99 / 19228, WO03 / 045805 and WO03 / 045806, all of which are incorporated herein in their entirety refer to. However, it is important to note that the threads on the closure and neck of the present invention are reversed relative to the threads described in these international applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com