Folding making process of shirt cuff

A production method and technology for shirts, applied in clothing, clothing, application and other directions, can solve problems such as easy falling off, cuffs cannot be kept relatively neat, and relative two edges of cuffs cannot be locked with each other. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

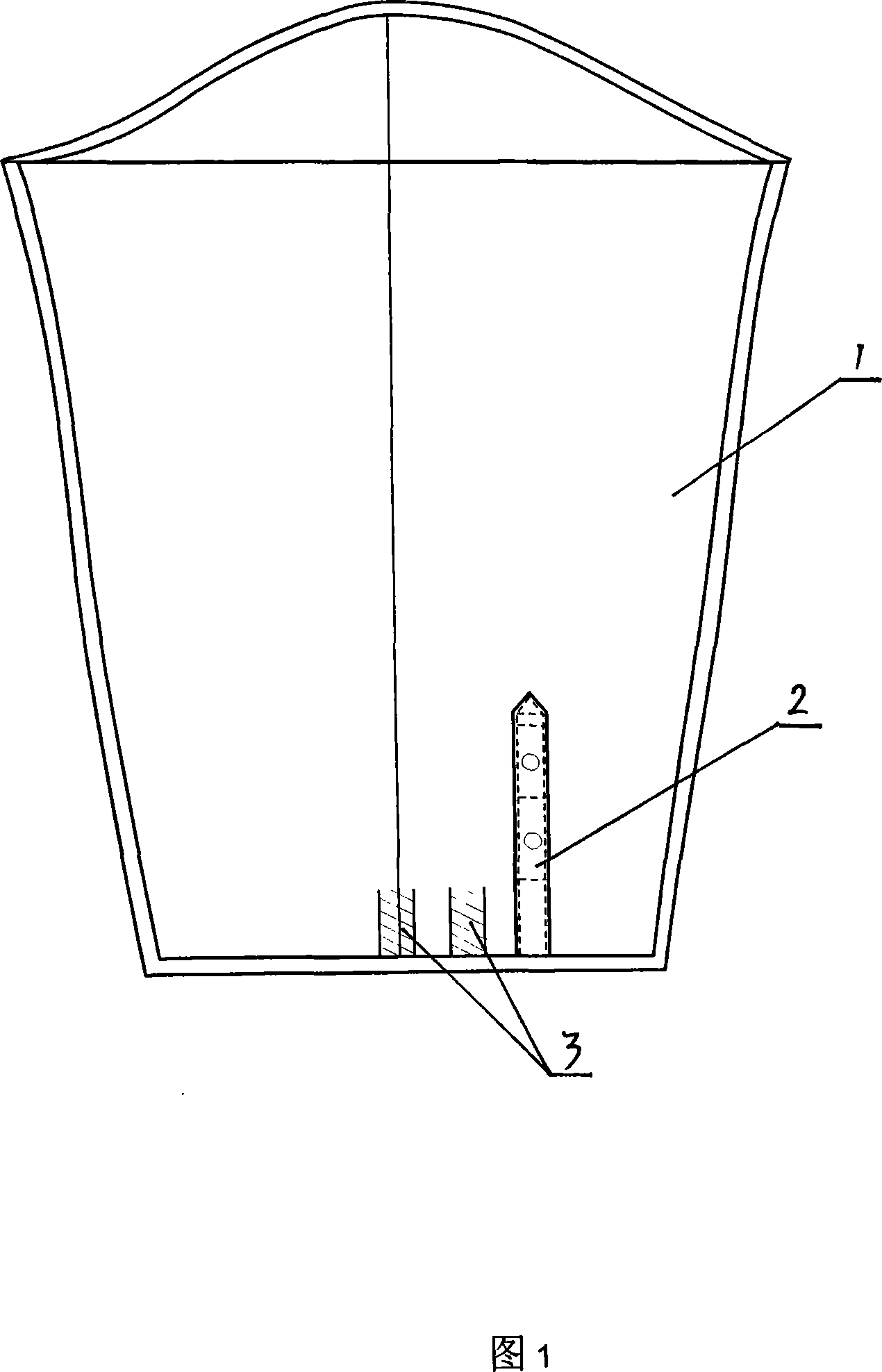

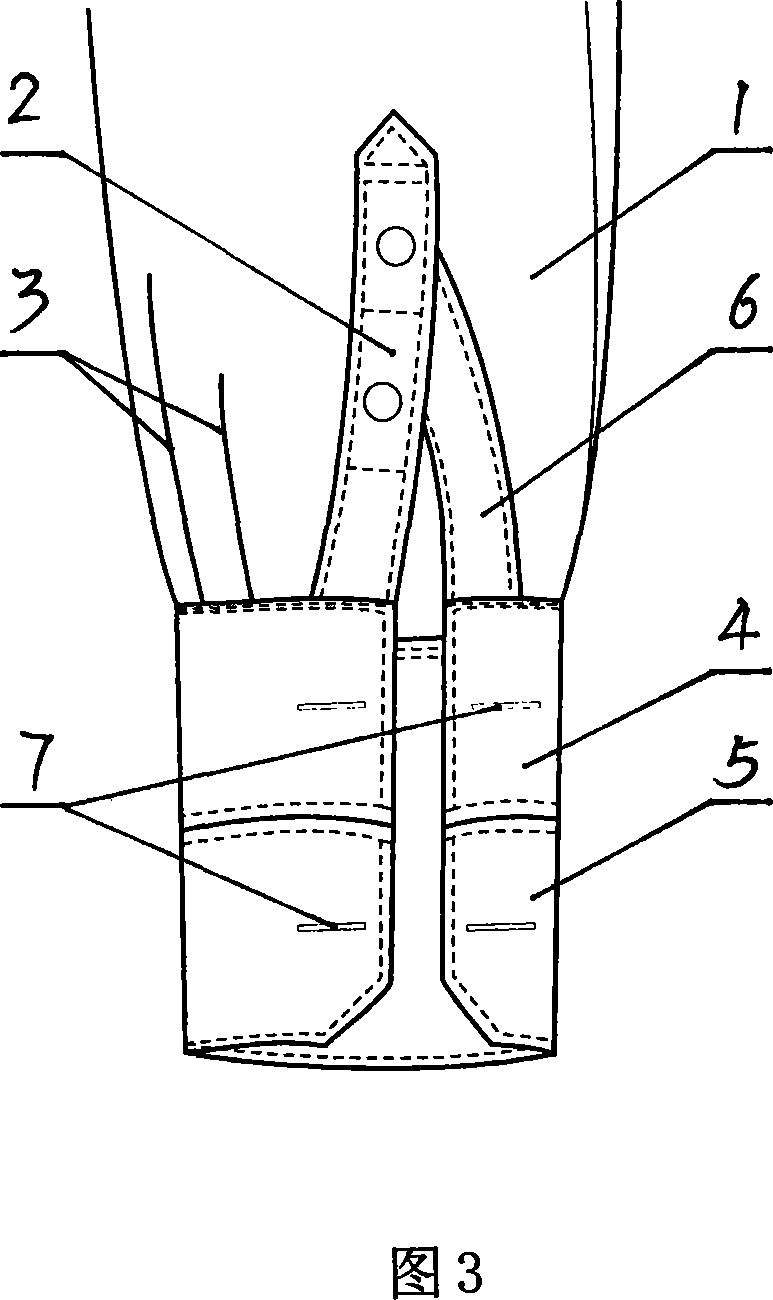

[0023] With reference to accompanying drawing, the folding manufacturing method of shirt cuff of the present invention comprises the following steps:

[0024] (1) Cutting the sleeve piece 1, the sleeve slit sword head 2, the sleeve slit rolling strip 6, the inner and outer pieces of the sleeve head, and the sleeve head lining. Sleeves, sleeve slit sword heads and sleeve slit rolling strips adopt conventional cutting methods to slit on the sleeves. The inner piece of the sleeve head and the lining of the sleeve head are rectangular in shape as a whole, and the shapes are corresponding;

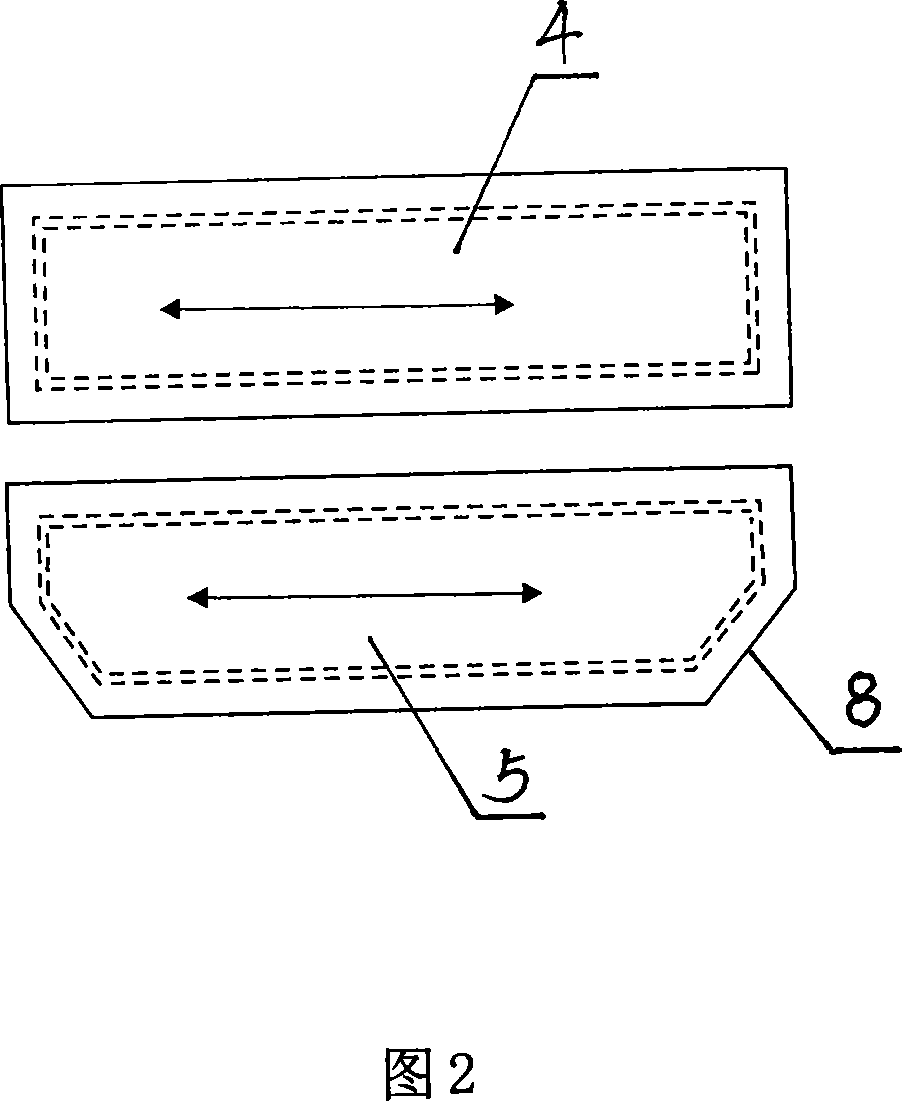

[0025] (2) Cut the corners of the sleeve head inner piece that is rectangular as a whole along one side of the length direction, and one of the sleeve head outer pieces 5 of the double rectangle is cut corners 8 along one side of the length direction, and the whole body is rectangular. The cuff lining is chamfered diagonally along one lengthwise side. The cuff length is equivalent to the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com