Offset press

A technology for printing presses and offset plates, applied in the field of operating offset printing presses, can solve problems such as troublesome adjustment mechanisms, and achieve the effects of eliminating vibration, short response time, high acceleration and moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

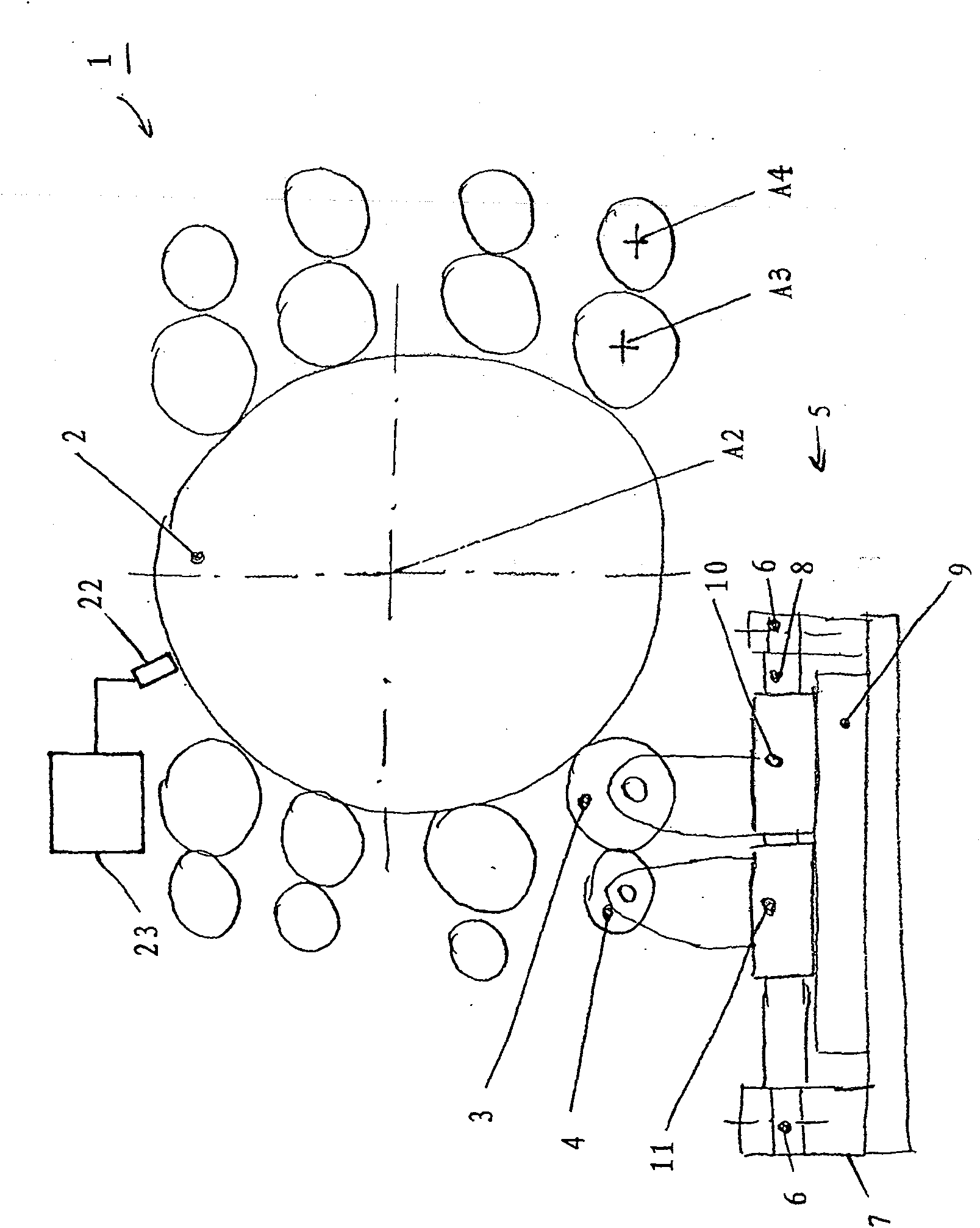

[0016] figure 1 The basic functional elements of the offset printing machine 1 are schematically shown. A central support roller 2 cooperates with the format roller 3 and the ink roller 4 . A not shown web of material to be printed bears against the surface of the support roller 2 . The format roll 3, which presses the material web against the support roll 2, has a printed sample on its surface. Printing ink is transferred from ink roller 4 to format roller 3 . In the exemplary embodiment shown, there are eight pairs each consisting of a format roller 3 and an ink roller 4 .

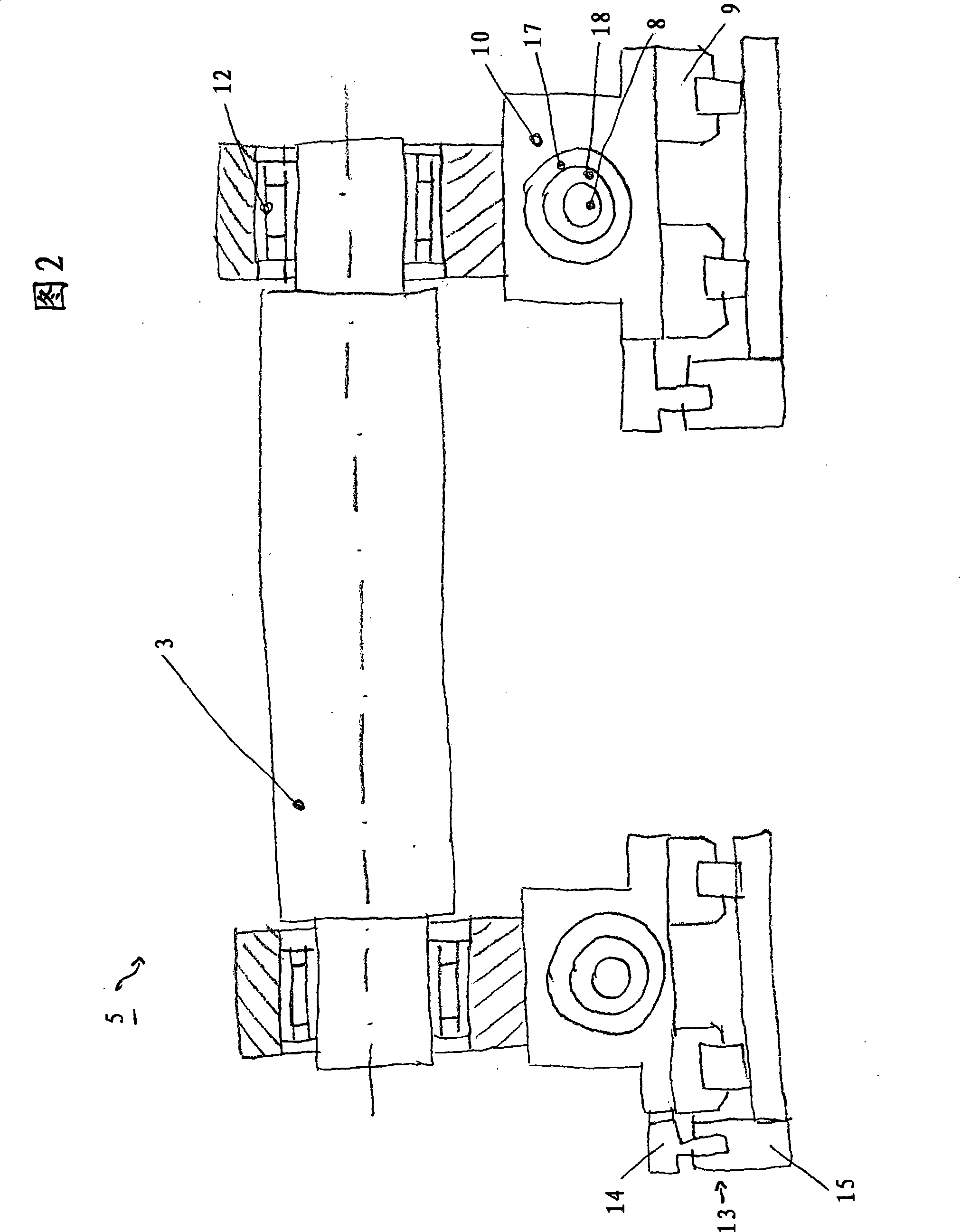

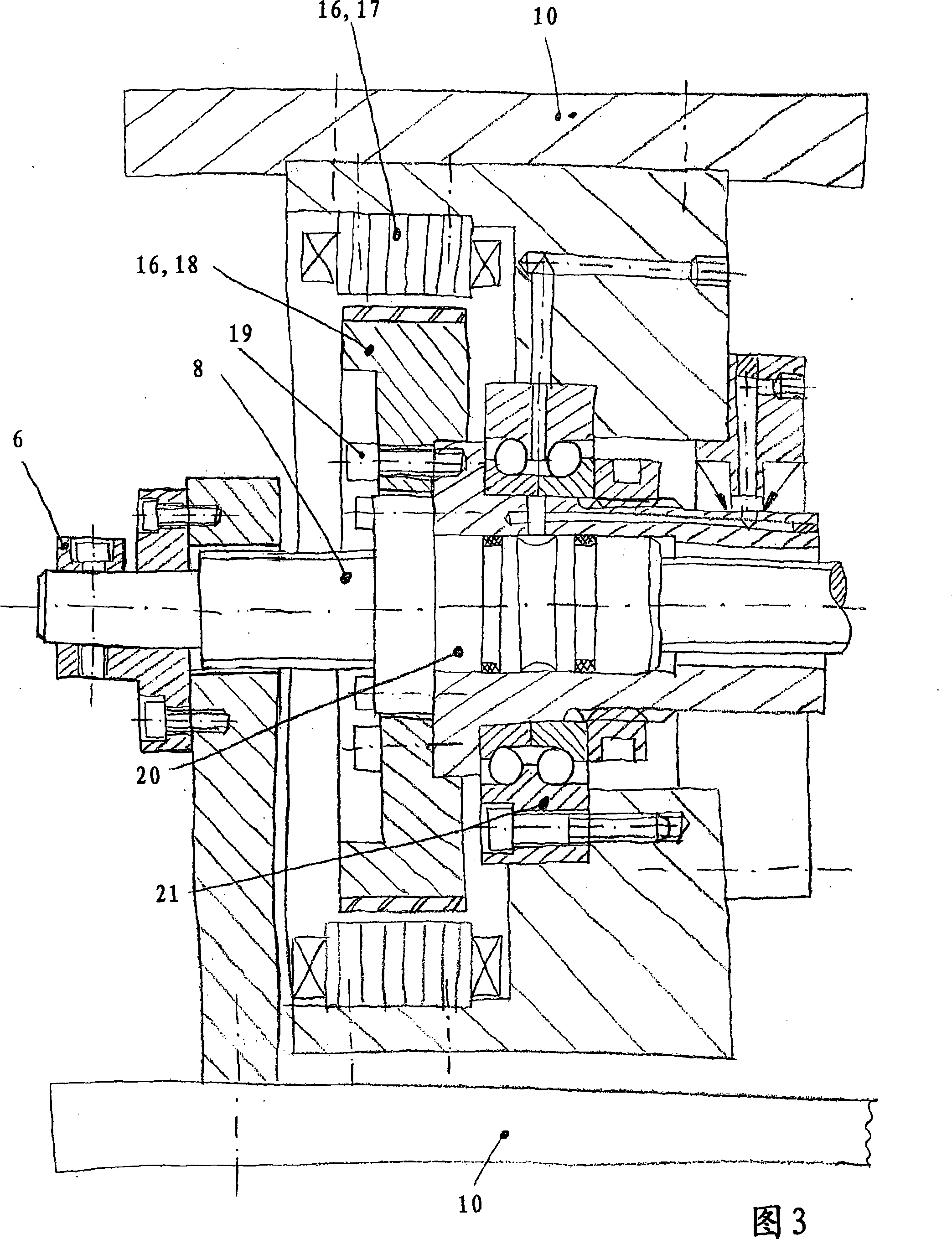

[0017] Both the format roller 3 and the ink roller 4 can be replaced when necessary. In order that each individual axis A3 of the format roller 3 and each axis A4 of the ink roller 4 can be adjusted relative to the axis A2 of the backup roller 2 , each pair of rollers 3 , 4 has a displacement device 5 . The displacement device 5 has a fixed spindle 8 , which is arranged on a frame 7 , for example by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com