Warp knitting machine

A warp knitting machine and motor technology, applied in the field of warp knitting machines, can solve the problems of unfavorable machine power, high cost, and limited working speed of warp knitting machines, etc., and achieve the effect of reducing space requirements and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

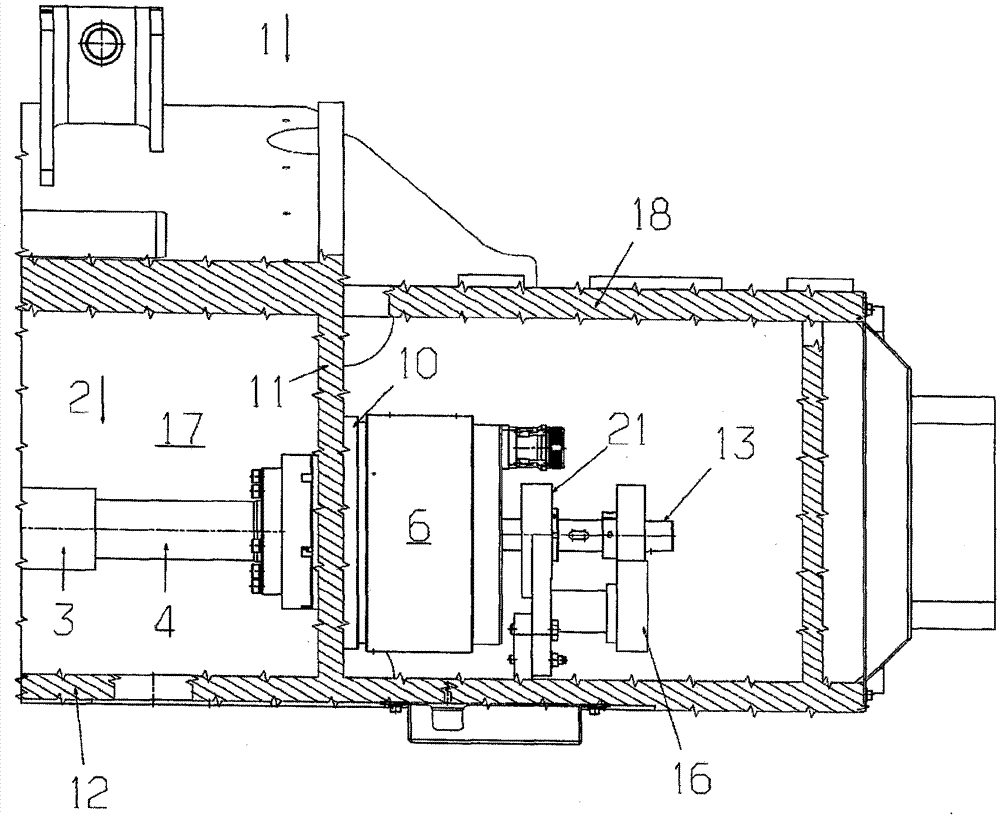

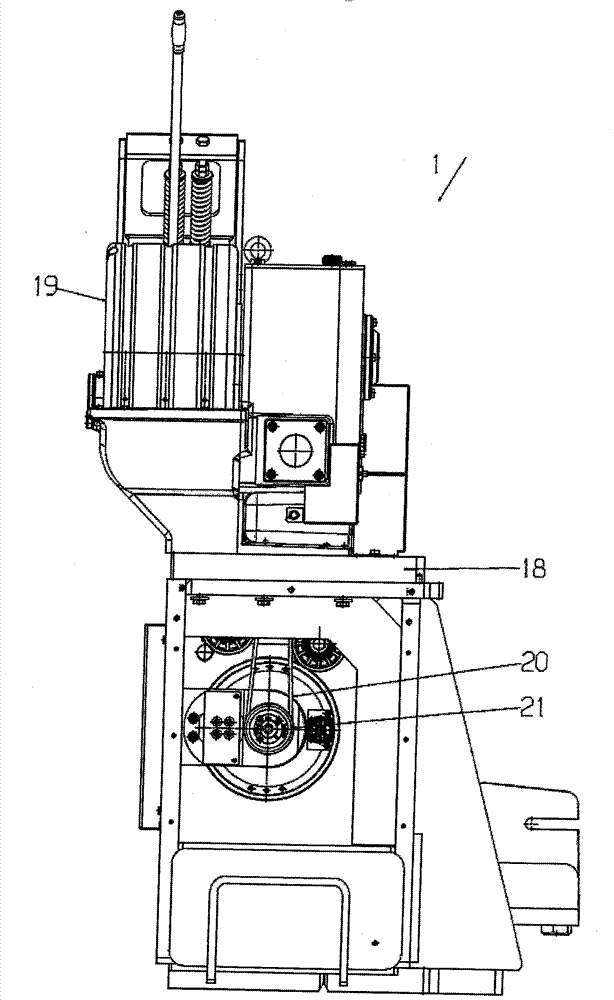

[0028] picture 1 A warp knitting machine is shown in section from above 1 the end of.

[0029] The warp knitting machine 1 with spindle 2 , the spindle has as the working section 3 to form the first segment and as terminal axis 4 to form the second segment. in the working area 3 In a manner not shown in detail above, a crankshaft transmission is fixed, which is used to drive the bar, wherein the bar supports the stitching tool in a known manner.

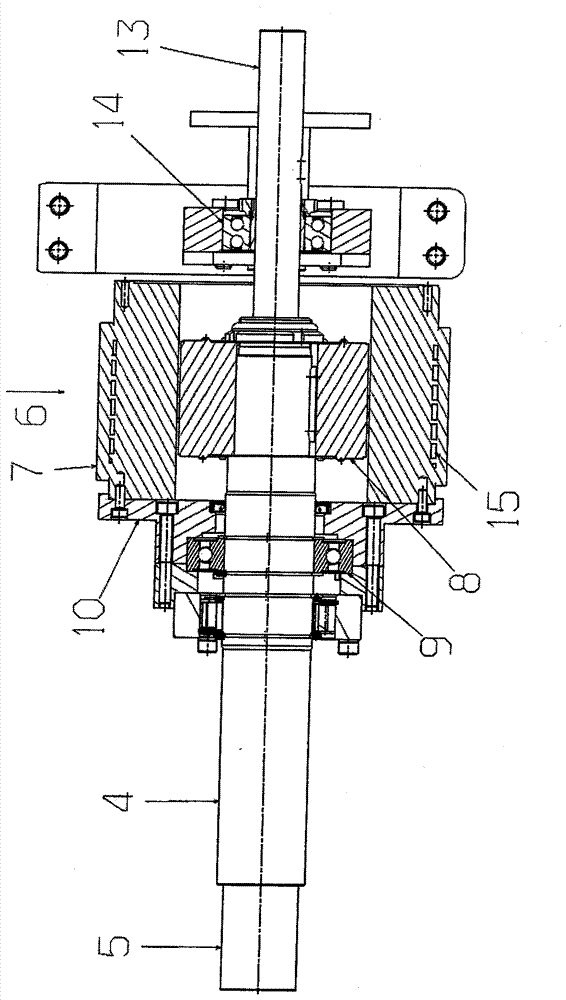

[0030] The working section 3 and the terminal axis 4 are rigidly but releasably connected to one another. as can be seen from Fig. 2 As seen in the terminal shaft 4 For this purpose there is a section with a reduced diameter 5 , the segment can be inserted into the spindle 2 working section 3 and then work with the section 3 connected.

[0031] In addition, the warp knitting machine 1 with drive motor 6 , the drive motor and the drive shaft 2 arranged coaxially. The driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com