Material arch preventing and breaking device with rotating shaft

A rotating shaft and arch-breaking technology, which is applied in the field of anti-arch and arch-breaking devices for silos, can solve problems such as life safety of critical employees, large one-time investment, and high labor intensity, and achieves simple construction, strong arch-breaking ability, and large power transmission area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

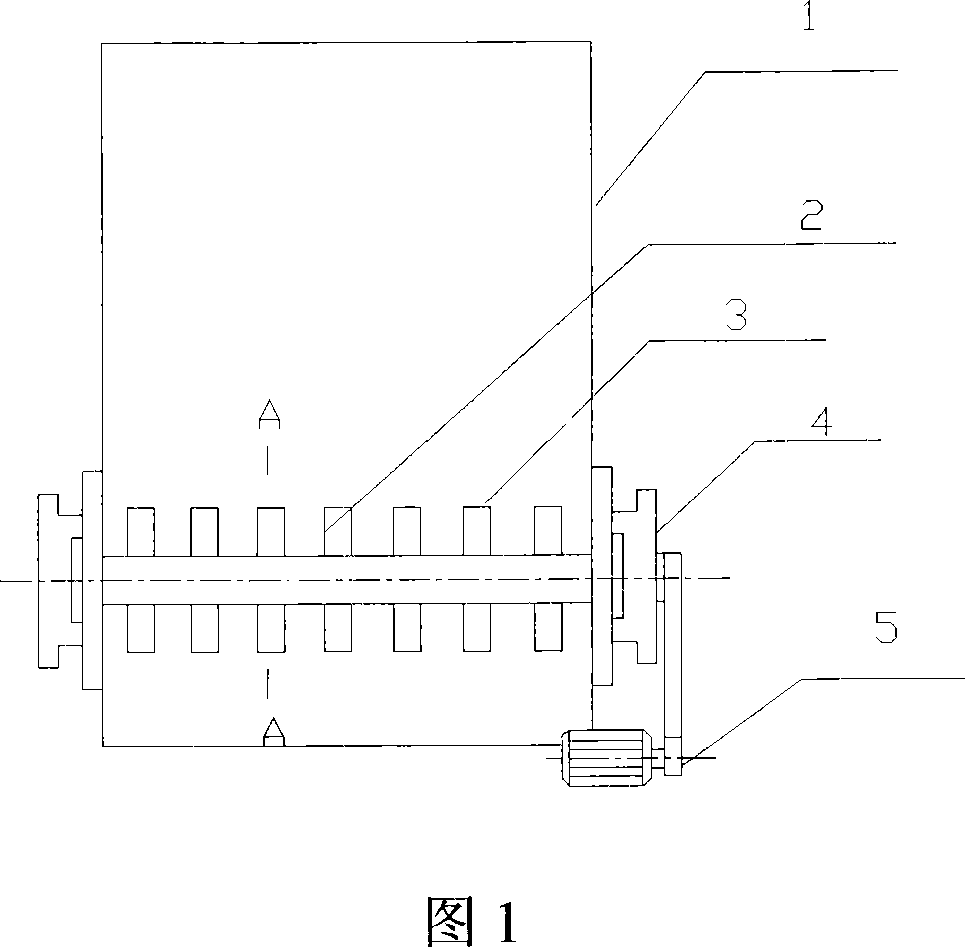

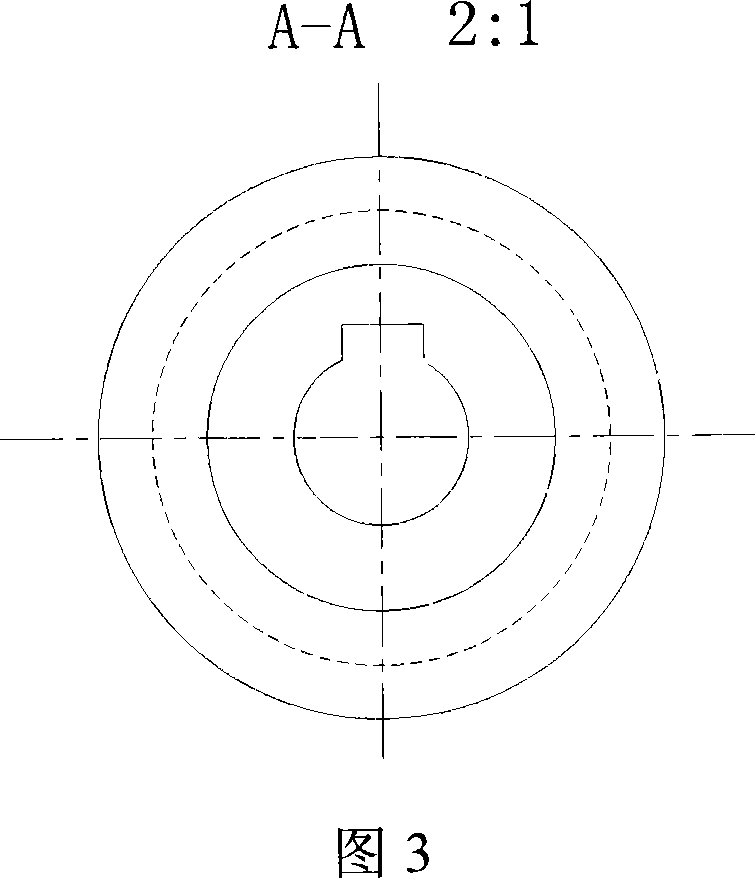

[0034] A set of arch-breaking rotating shafts is installed at the outlet of the warehouse body. It is suitable for all kinds of silos with small silo body and not serious arching.

Embodiment 2

[0036] Two sets of arch-breaking rotating shafts are installed symmetrically at the outlet of the bin body. The device can work all the time to prevent the coal bunker or material bunker from arching or shed (canopy), or it can only work when arching occurs.

Embodiment 3

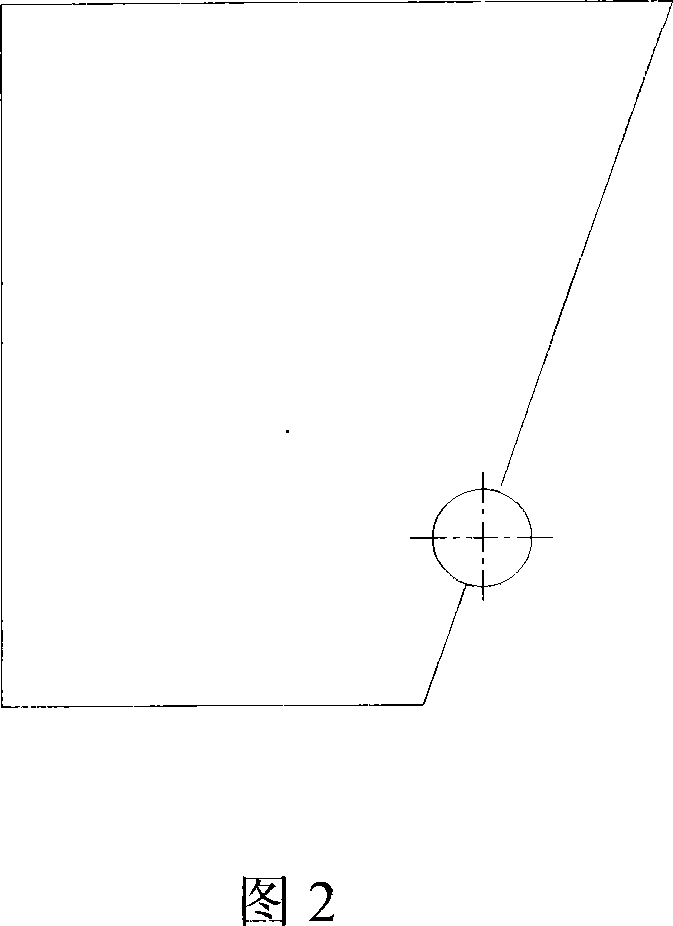

[0038] When the lateral size of the coal bunker is too large, install two sets of arch-breaking rotating shafts on the horizontal line at the same height of the bunker wall. A coal drop slope is formed between the exit of the coal bunker and the surface of the rolling gear row of the rotating shaft. The slope determines the amount of coal falling and the pressure on the bottom row of teeth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com