Device for efficiently preventing hopper material bridging and wall adhering

A hopper and material technology, which is applied in the field of anti-bridging and anti-sticking wall devices for silo blanking pipes, can solve the problems of not being able to ensure 100% arch breaking or preventing wall sticking, low work efficiency, single technology, etc. The ability to stick to the wall and break the arch, the installation and construction are simple and convenient, and the effect of avoiding the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

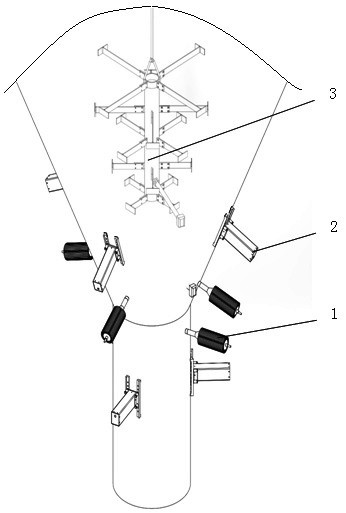

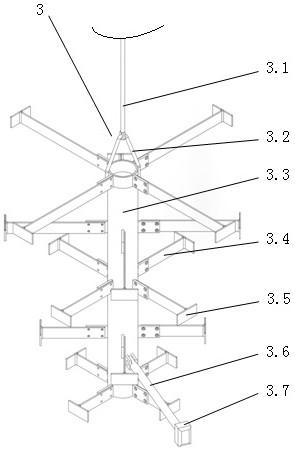

[0043] Such as figure 1 As shown, the ultrasonic phase-shifting vibrator 1 and the high-frequency electromagnetic vibrator 2 are respectively installed on the outer wall of the feeding pipe of the silo; the ultrasonic phase-shifting vibrator 1 includes an ultrasonic vibration transmission rod, an ultrasonic transducer, an ultrasonic special cable and Ultrasonic controller; the ultrasonic vibration transmission rod of the ultrasonic phase-shifting vibrator 1 can be directly welded on the outer wall of the silo blanking tube, or can be threaded through a special joint; when the inner wall of the silo blanking tube has a thin metal interlayer , the ultrasonic vibration rod should be directly connected with the internal thin-walled metal plate;

[0044] The high-frequency electromagnetic vibrator 2 is connected with the outer wall of the silo feeding pipe through the rapper bracket, and the rapper bracket 2.1 is welded on the outer wall of the silo feeding pipe; the impact head of...

Embodiment 2

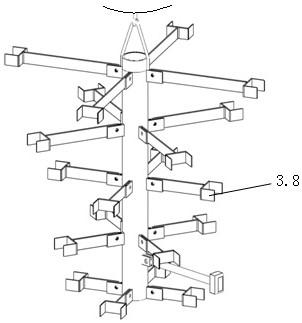

[0053] On the basis of Embodiment 1, the arch breaker 3 also has an alternative structure, such as image 3 shown in figure 2 On the basis of the broken arch plate 3.5, a near-wall broken arch plate 3.8 is arranged, and the two ends of the near-wall broken arch plate 3.8 protrude and are similar to the inner wall of the silo blanking pipe; when working, it not only has a good arch-breaking function, but also It also has a good wall cleaning function.

Embodiment 3

[0055] On the basis of Embodiment 1, the installation method of the arch breaker 3 in the silo blanking tube is changed to use the support frame 4 to hoist the arch breaker 3 in the silo blanking tube. In the actual use process, the support frame 4 The installation position is the easiest place to bridge in the silo drop pipe;

[0056] Such as Figure 4 As shown, the arch breaker spreader 3.1 is connected to the support frame 4, and the support frame 4 includes a support center piece 4.1, a support piece 4.2, a support base 4.3, and a positioning piece 4.4; one end of the three support pieces 4.2 is movably connected with the support center piece 4.1, and the support The other end of the piece 4.2 is connected with the inner wall of the silo discharge pipe, and is supported at an equal angle; the end of the support 4.2 connected with the inner wall of the silo discharge pipe is provided with a support base 4.3, and the support base 4.3 is used for falling with the silo. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com