Swivel device

A technology of swivel and sealing device, which is applied in the direction of engine sealing, adjustable connection, pipe/pipe joint/pipe fitting, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] To facilitate the understanding of the present invention, equivalent reference numerals are used for equivalent elements throughout the drawings.

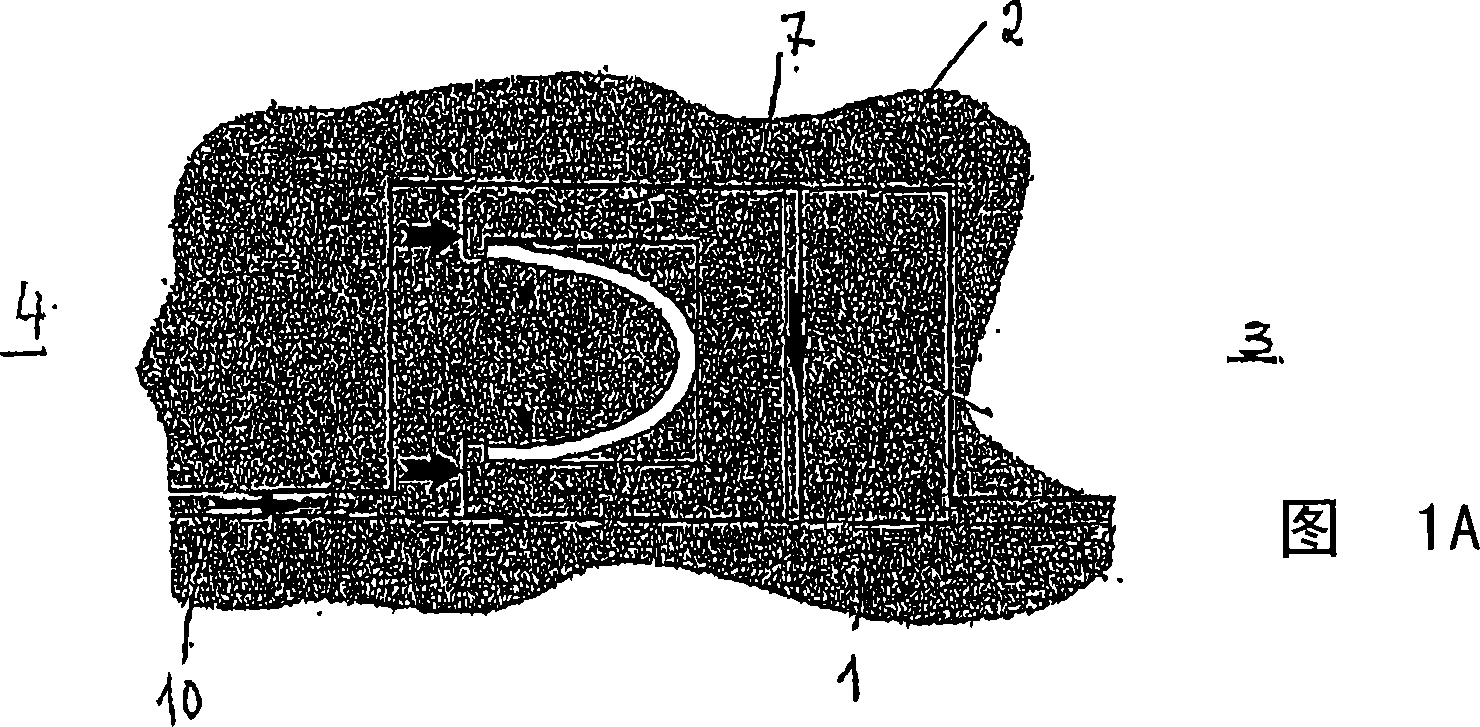

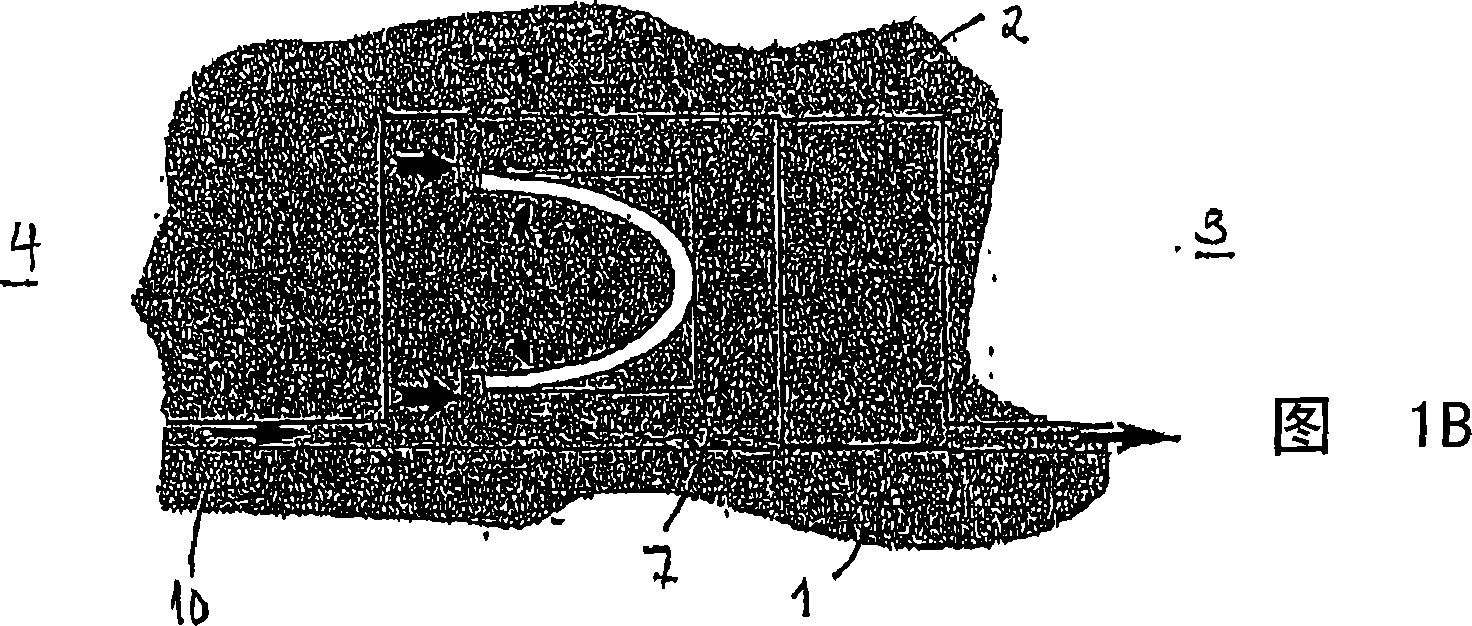

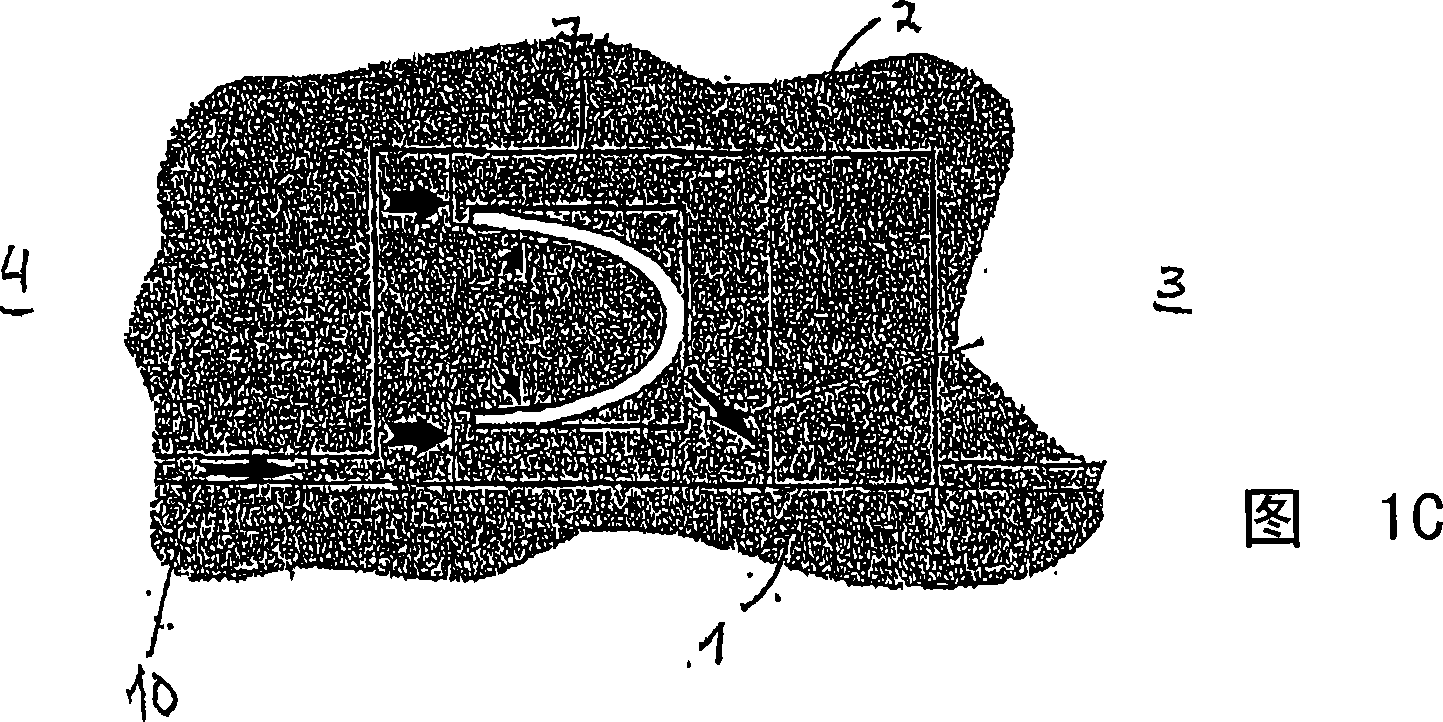

[0023] Figures 1A-1C illustrate the three main principles of how barrier pressure operated dynamic seals leak. The seal is located between two opposing surfaces, one of which comprises a first element 1 , which may be a rotating element, and a second element 2 , which may be a stationary element. The sealing device comprises a sealing body 7 . In the embodiment shown, the sealing body 7 is designed such that the barrier fluid supplied via the supply line 10 forces the sealing body 7 into abutment against the first and second elements 2, respectively. The seal is located between the process channel 3 and the environment 4 . As shown in FIG. 1A , leakage can occur between the sealing body 7 and the surface of the second element 2 , thereby preventing fluid from leaking through the sealing body 7 towards the process channel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com