A sample mixing device applied to column chromatography

A technology of column chromatography and conveying device, applied in the field of sample mixing device, can solve the problems of large solvent loss, inability to achieve continuity, and troublesome operation, and achieve the effects of low solvent content, large solvent vapor condensation area, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with accompanying drawing, the present invention is described in further detail.

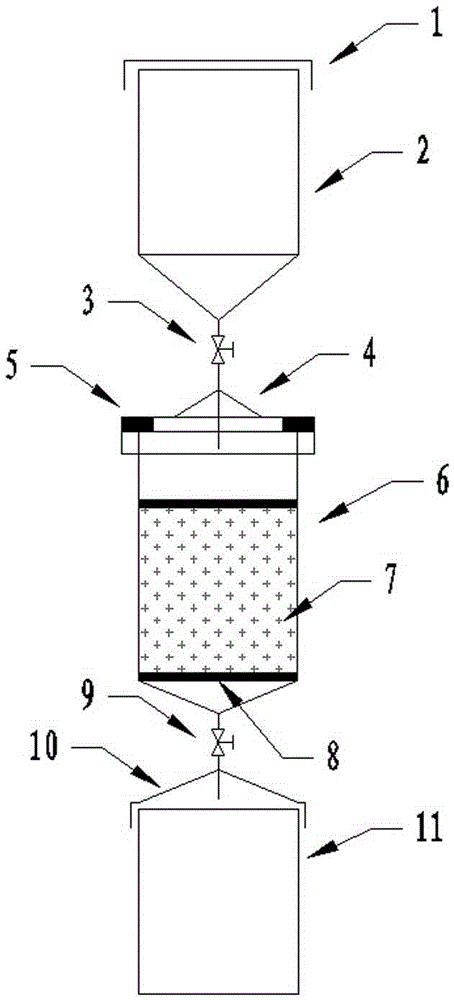

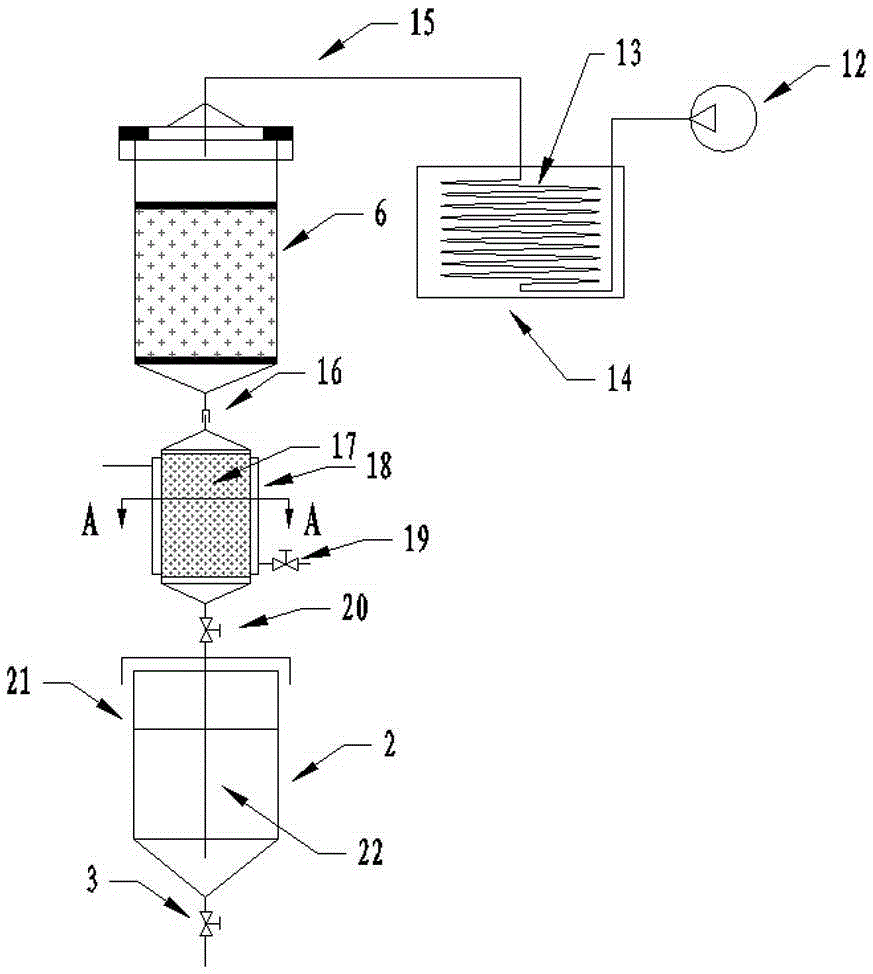

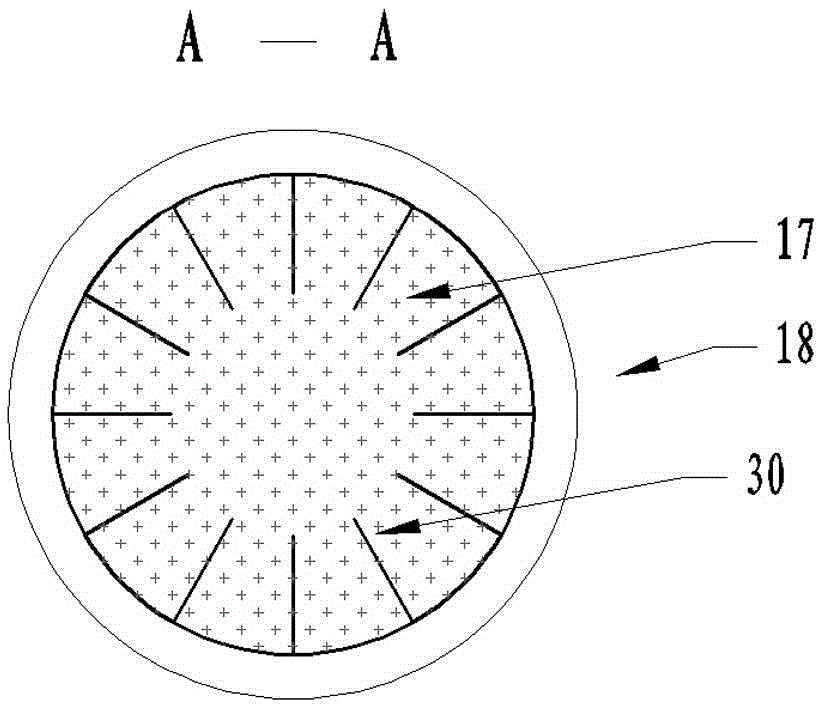

[0025] Such as figure 1 , figure 2 and image 3 The sample mixing device shown in the column chromatography includes a separatory funnel 2, an adsorption cup body 6, a turnover cup 11, a condenser and a gas delivery device. The adsorption cup body 6 is a cylindrical cone-bottomed structure with a filter plate 8 at the bottom , the cup body 6 is provided with a movable filter plate; the adsorption cup 6 is provided with a cup cover 4 and a sealing gasket 5 to realize sealing, and there is a small hole in the middle of the cup cover 4 to realize the detachable sealing connection with the separating funnel 2 and the air pipe 15; the adsorption cup There is a valve 9 at the bottom of the body 6 to connect the micropipe to realize the detachable and sealed connection with the turnover cup 11 and the condenser; the condenser is a jacket structure made of copper or aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com