Method and apparatus for determining working stroke of cylinder of internal combustion engine

A technology of working stroke and internal combustion engine, applied in electrical control, mechanical equipment, engine control, etc., can solve problems such as the distribution of unworkable strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

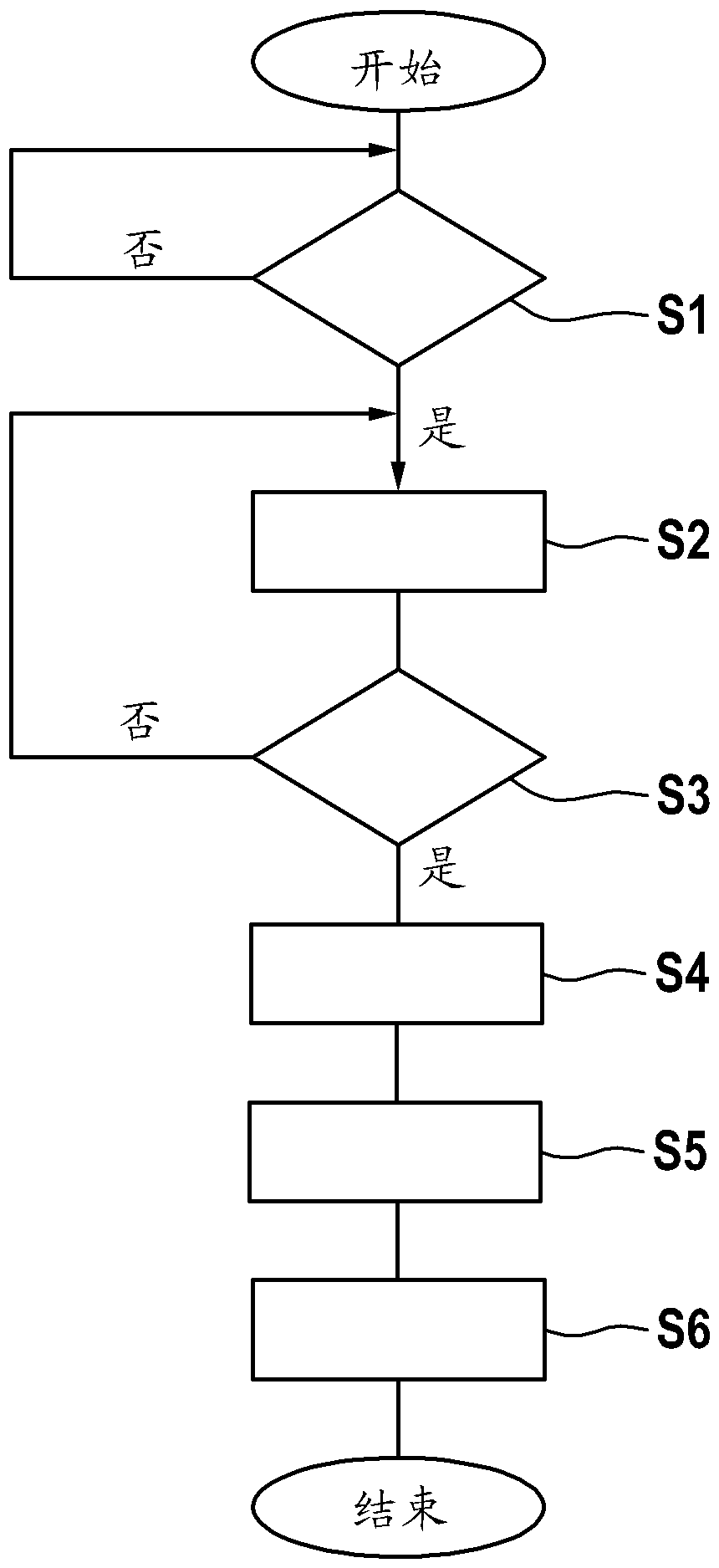

Method used

Image

Examples

Embodiment Construction

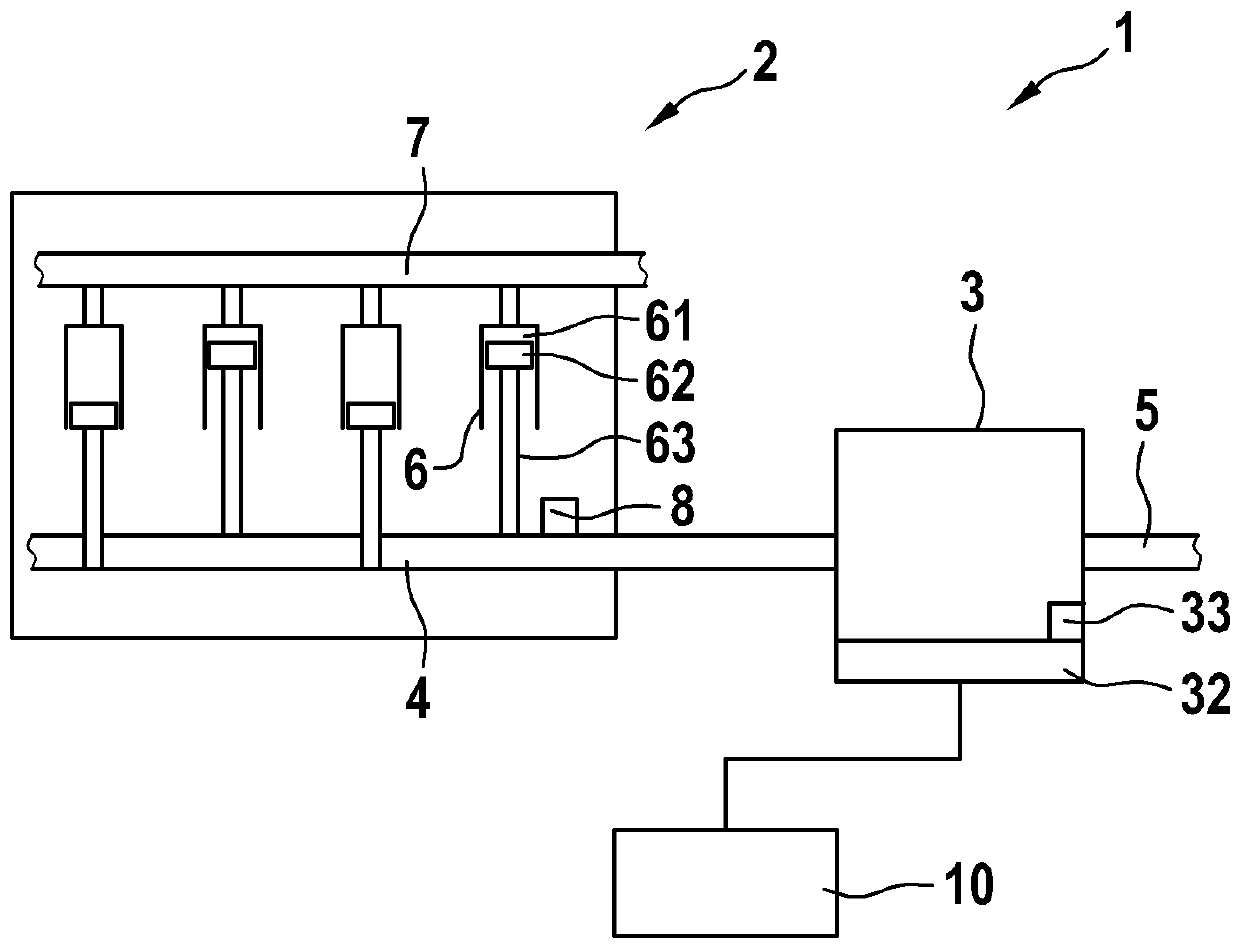

[0029] figure 1 A motor system 1 with a hybrid drive having an internal combustion engine 2 and an electric drive 3 is shown schematically. Internal combustion engine 2 includes a crankshaft 4 which is mechanically coupled to an electric drive 3 for providing a common drive torque via an output shaft 5 . It can be directly coupled to the output shaft via a clutch, belt or the like.

[0030] The drive torque results as a sum of the motor torque of internal combustion engine 2 and the electric drive torque of electric drive 3 .

[0031] The crankshaft 4 is coupled to the cylinders 6 of the internal combustion engine 2 , each cylinder 6 having a combustion chamber 61 and a combustion chamber movable piston 62 . The piston is mechanically coupled to the crankshaft 4 via a connecting rod 63 in such a way that the up and down movement of the piston 62 is converted into a rotational movement of the crankshaft 4 .

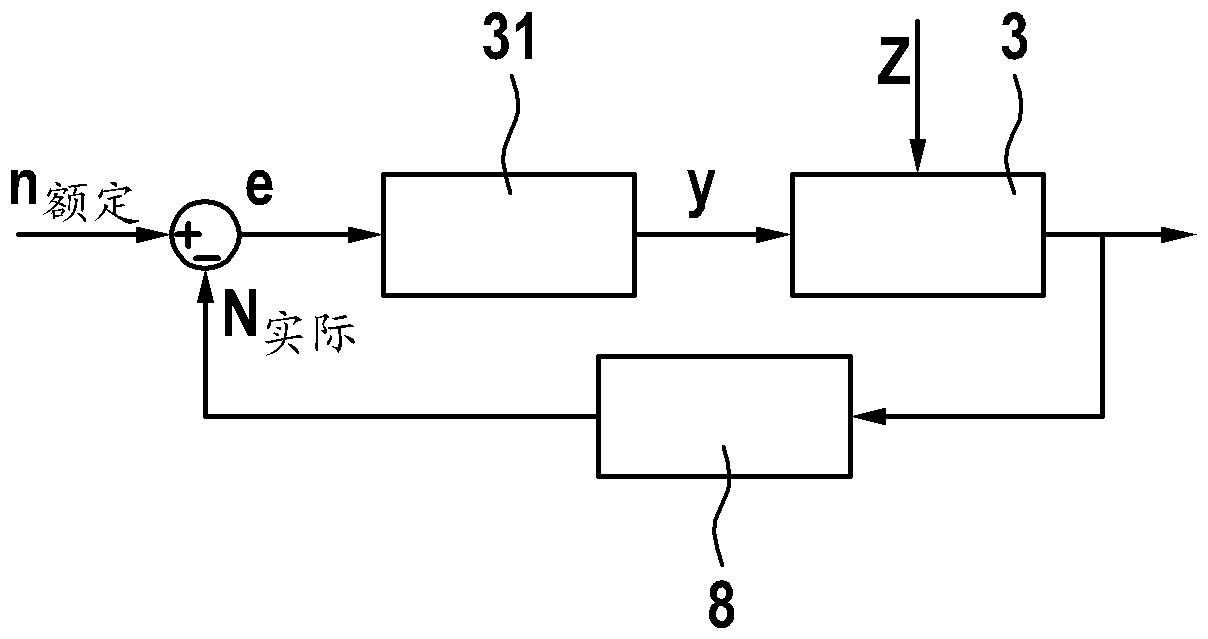

[0032] A motor controller 10 is provided which operates the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com