Heat exchanger and its manufacturing method

A technology of heat exchangers and manufacturing methods, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of very expensive leakage reliability, difficult operation, reduction, etc., and achieve low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

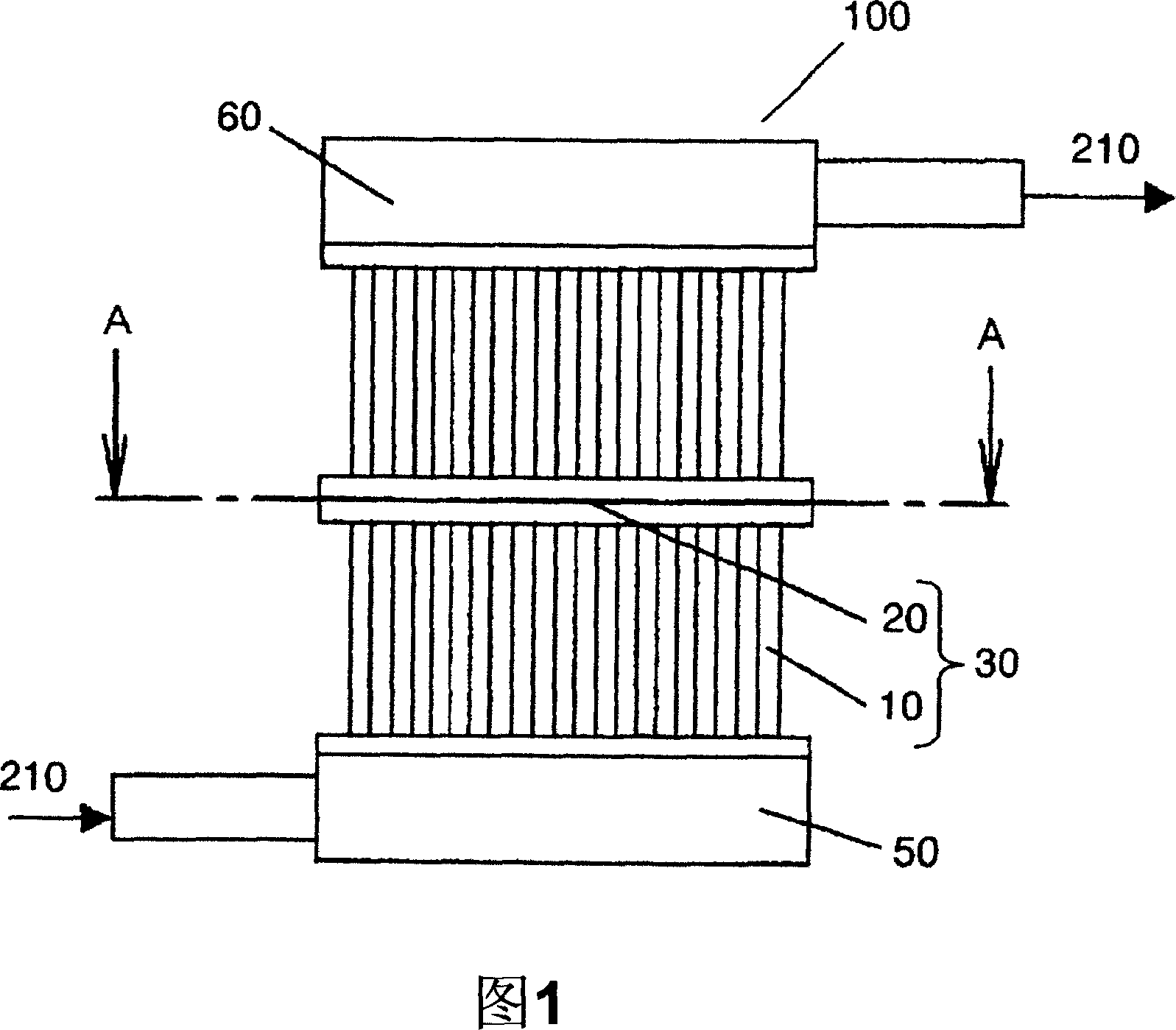

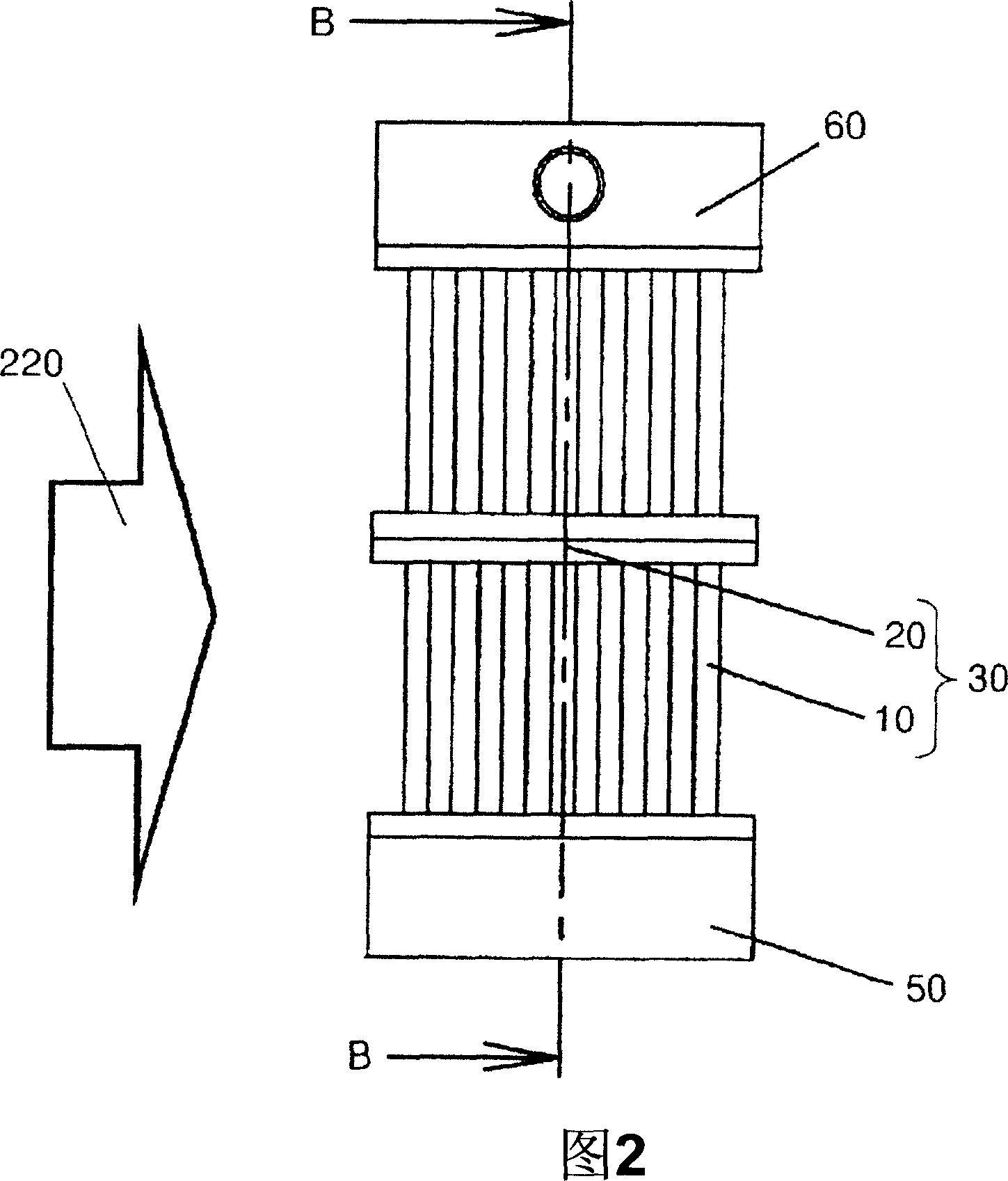

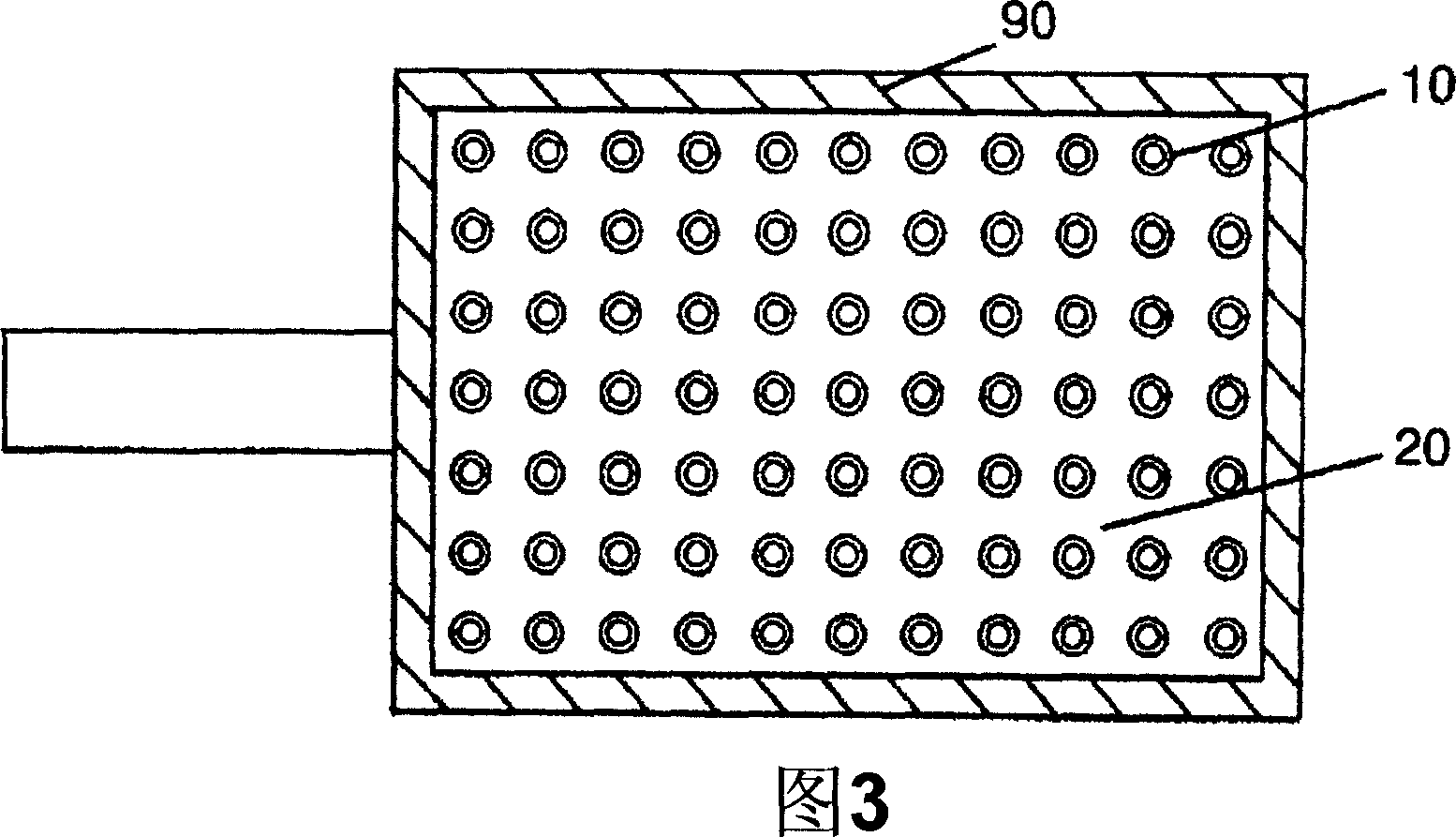

[0080] FIG. 1 is a front view of a heat exchanger according to Embodiment 1 of the present invention, and FIG. 2 is a side view. Fig. 3 is a sectional view of line A-A in Fig. 1, and Fig. 4 is a sectional view of line B-B in Fig. 2 .

[0081] As shown in FIGS. 1 to 4 , the heat exchanger 100 according to Embodiment 1 has a tube group block 30 composed of tubes 10 and substrates 20 . Furthermore, the two-layer tube group blocks 30 are connected by joining each other on the periphery 90 of the base plate 20 along the tube axis of the tube 10, and the inlet cover 50 and the outlet cover 60 are provided at both ends in the vertical direction.

[0082] In this embodiment, the tube 10 is a round tube and is provided with an internal fluid flow path. Furthermore, the shape of the pipe 10 may not be a round pipe. For example, it may be a tube having a rectangular cross-sectional shape, a polygonal tube, or an elliptical tube. In addition, the peripheries 90 of the substrate 20 are ...

Embodiment approach 2

[0100] Fig. 8 is a front view of a heat exchanger according to Embodiment 2 of the present invention, and Fig. 9 is a side view thereof. FIG. 10 is a sectional view along line C-C in FIG. 8 , and FIG. 11 is a sectional view along line D-D in FIG. 9 .

[0101] In FIGS. 8 to 11 , the heat exchanger 200 has a tube group block 130 composed of tubes 110 and a base plate 120 . Furthermore, the two-layer tube group blocks 130 are connected by jointing on the periphery 190 of the substrate 120 along the tube axis direction of the tube 110, and the inlet cover 150 and the outlet cover 160 are provided at both ends in the vertical direction.

[0102] In Embodiment 2, the cross-sectional shape of the tube 110 is flat, and the plurality of channels 115 are arranged along the longitudinal direction. The plurality of tubes 110 are provided on the substrate 120 so that their longitudinal directions are parallel to each other and at a predetermined interval therebetween. The peripheries 190...

Embodiment approach 3

[0117] Fig. 15 is a front view of a heat exchanger according to Embodiment 3 of the present invention, and Fig. 16 is a side view thereof. FIG. 17 is a sectional view along line A-A in FIG. 16 , and FIG. 18 is a sectional view along line B-B in FIG. 16 . In addition, the same code|symbol is attached|subjected to the same element as Embodiment 1, and the description is simplified.

[0118] In FIGS. 15 to 18 , a heat exchanger 300 has a tube group block 40 composed of tubes 10 , base plates 20 and spacers 80 . Furthermore, the tube group block 40 is stacked in three layers along the flow direction of the internal fluid flowing in the tube 10, and the inlet cover 50 and the outlet cover 60 are provided at both ends in the vertical direction. Here, the spacer 80 is a portion protruding from the substrate in a stepwise manner at the periphery of the substrate 20 with a predetermined height and width.

[0119] In this embodiment, the tube 10 is a round tube and is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com