Metal tube shaping apparatus

A technology of shaping device and round tube, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of out-of-tolerance shape ovality, scrapping, affecting assembly quality, etc., and achieve the effect of accurate guidance and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

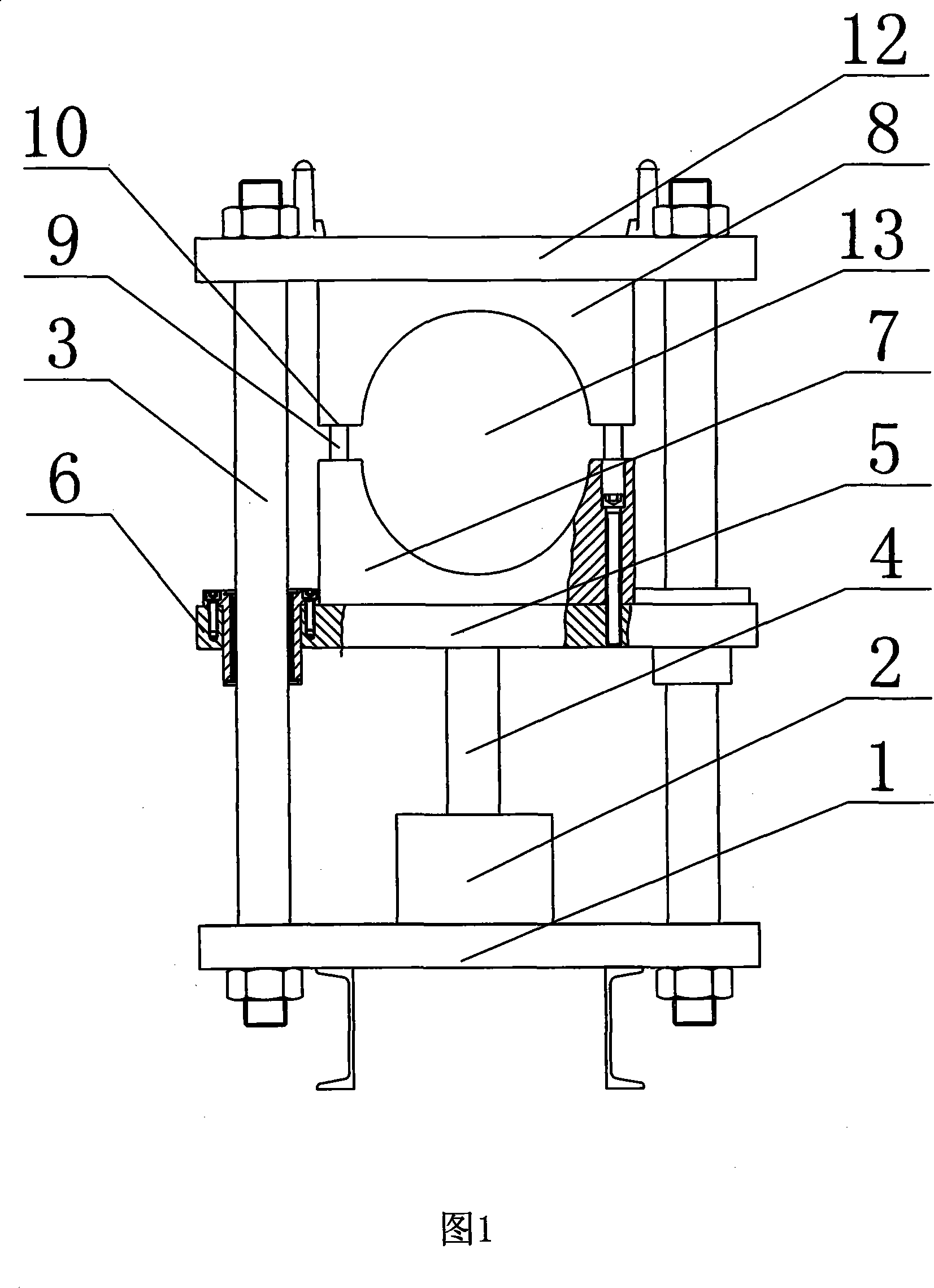

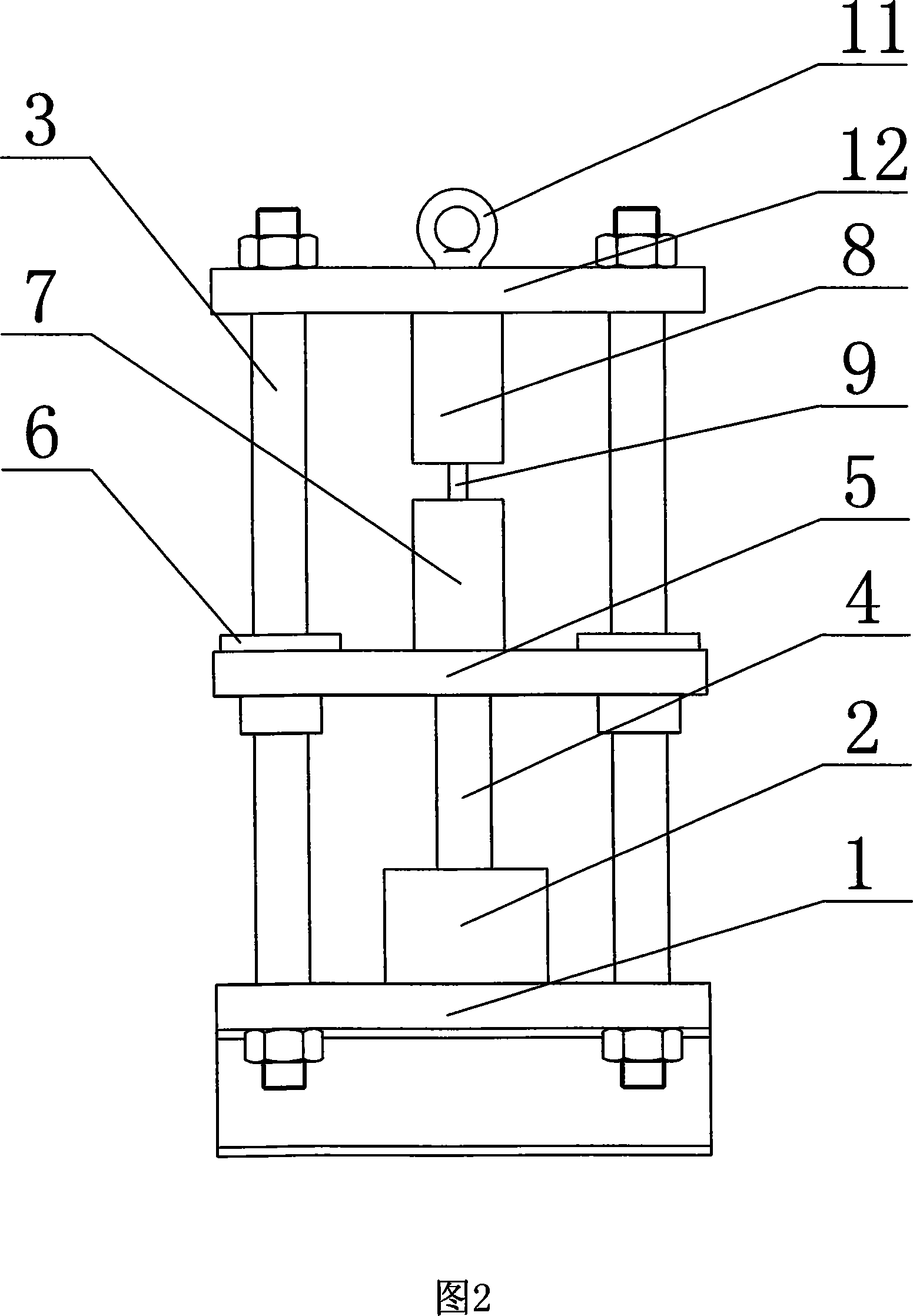

[0011] As shown in Figure 1 and Figure 2: a metal circular tube shaping device, including: a base 1, a jack 2 is arranged on the base 1, and a tension rod 3 and a piston rod 4 of the jack 2 are respectively arranged at both ends of the base 1 The middle lifting plate 5 is arranged on the top, and the two ends of the middle lifting plate 5 are movably arranged on the tension rod 3 through the bearing 6. The lower half mold 7 is arranged on the top of the middle lifting plate 5, and the lower half mold 7 is arranged on the top of the tension rod 3. 7 matched upper half mold 8, upper half mold 8 is arranged on the top plate 12 of tension bar 3 tops by eyebolt 11. In order to guide the metal round pipe shaping device accurately during the shaping process, a guide rod 9 is provided on the lower half mold 7 , and a guide hole 10 matched with the guide rod 9 is provided on the upper mold half 8 .

[0012] The working process of the metal tube shaping device with the above structure i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap