Method for making synthesized leather with metal luster

A technology of metallic luster and manufacturing method, which is applied in metal layered products, chemical instruments and methods, lamination devices, etc., can solve the problems of large performance differences, short lifespan, different lifespans, etc., and achieves simple and practical manufacturing methods. Long life and soft properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

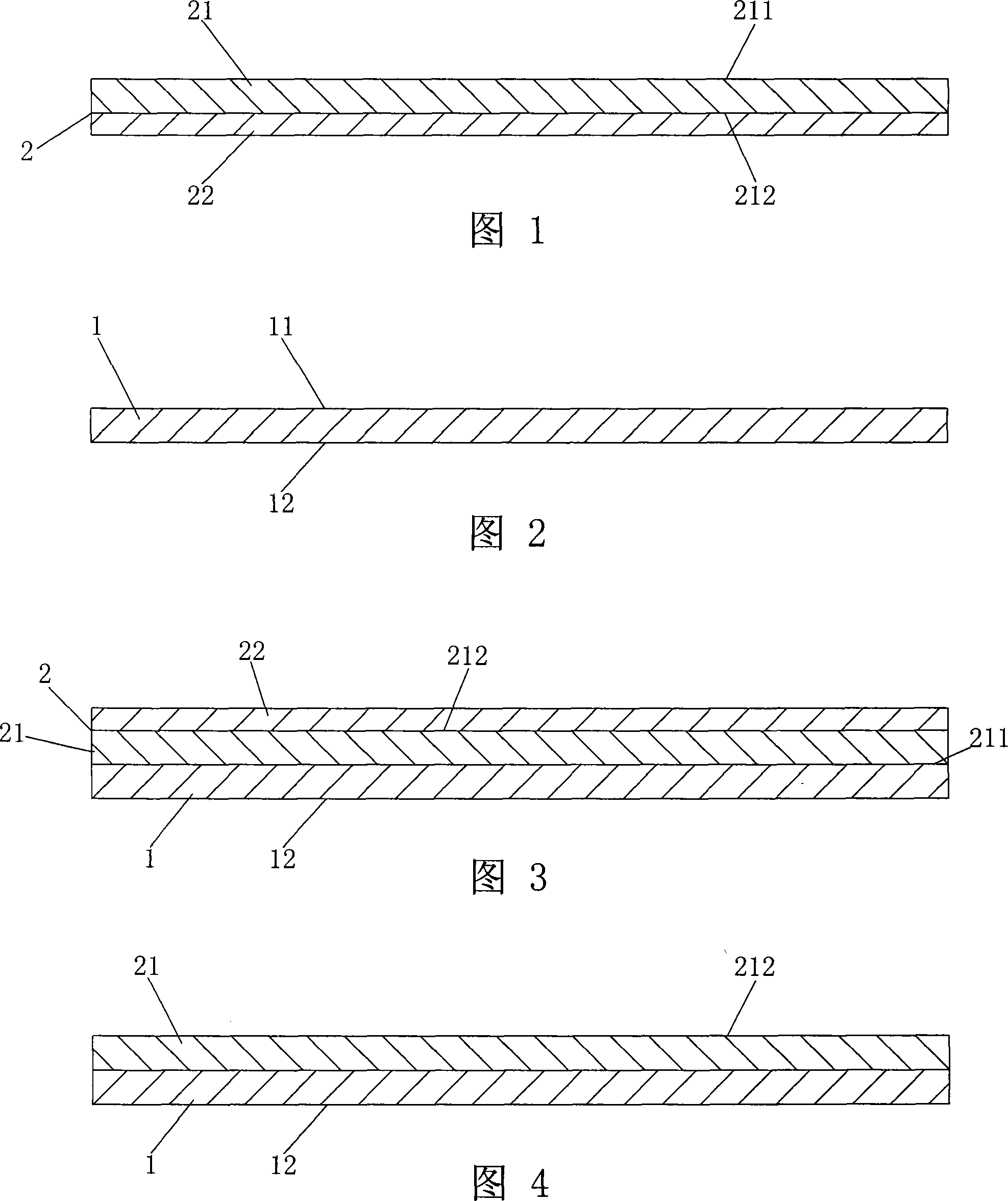

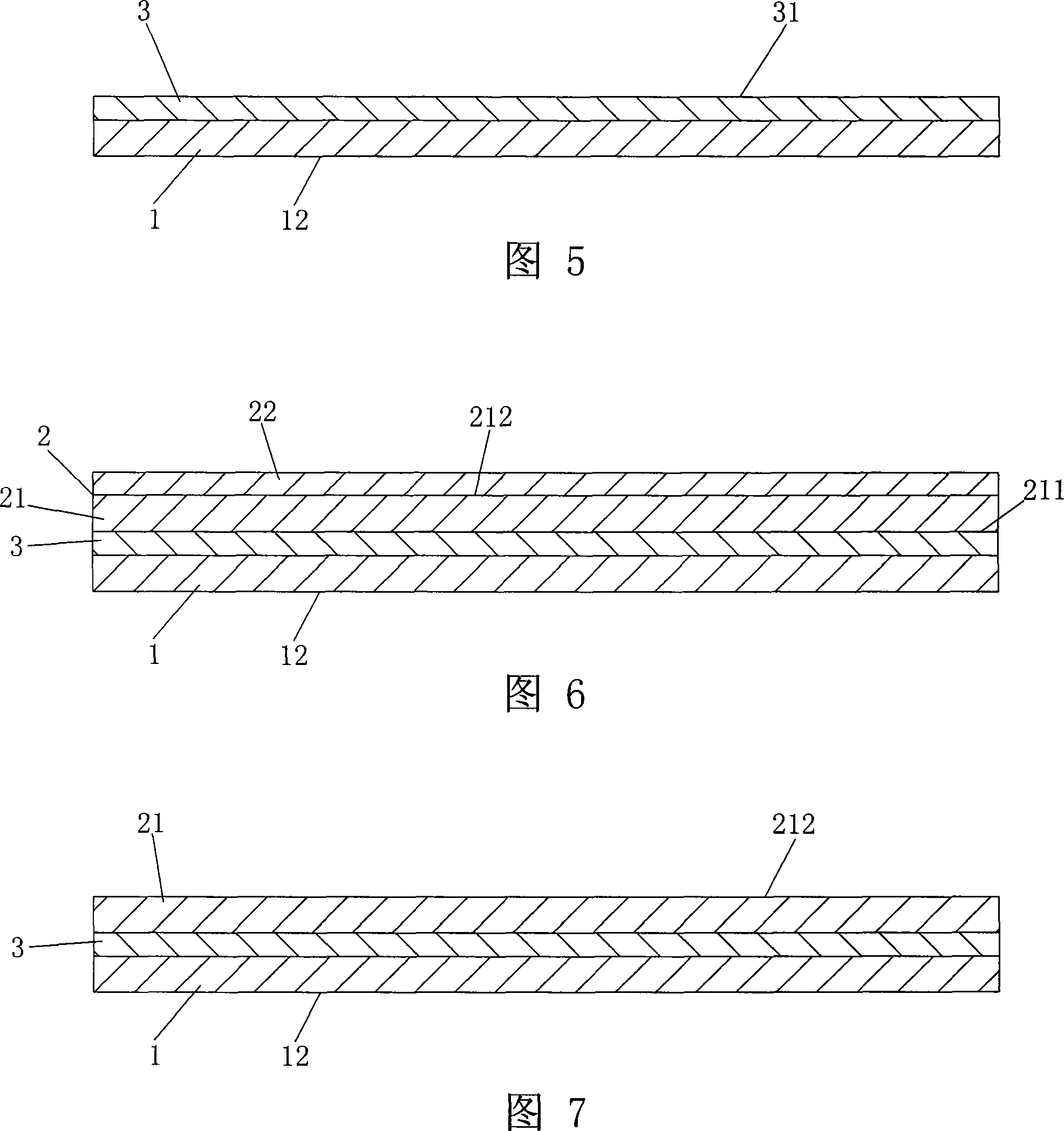

[0019] As can be seen from Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention includes the base material 1 that has also processed top surface 11 and bottom surface 12 and the full metal film 21 and base material 22 that also contain metal film 21 and substrate 22 through vacuum plating. Mask 2, base material 1 and full-face film 2 first transfer full-face film 2 to base material 1 by transfer method, wherein the top surface 211 of metal film 21 is transferred to the top surface 11 of base material 1; then tear off the base material 22. Make the contact bottom surface 212 of the metal film 21 and the substrate 22 face outward, thereby forming a synthetic leather with metallic luster. Some substrates 1 (such as materials such as PVC) can directly use the transfer method without being provided with a glue layer 3 (as shown in Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com