Cable for boarding bridge

A boarding bridge and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of cables not conforming to environmental protection, cutting cable cores, fatigue cracking of cable sheaths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

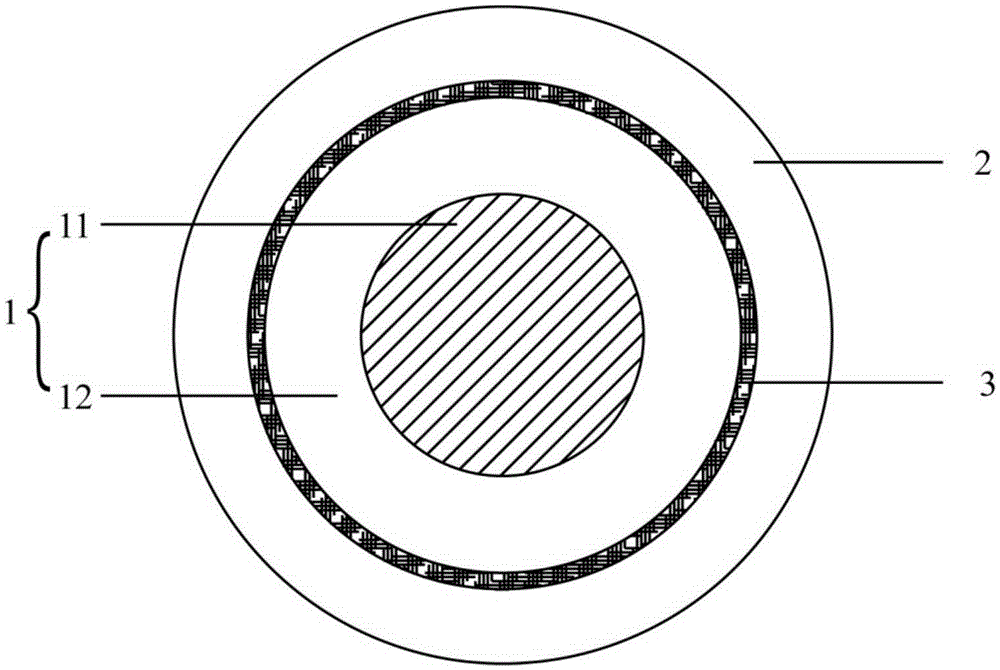

[0027] Such as figure 1 A kind of boarding bridge cable shown comprises a lead 1, and lead 1 comprises the insulation layer 12 of conductor 11 and cladding conductor 11; The outermost layer of cable is outer sheath layer 2; Described insulation layer 12 and A wrapping layer 3 is arranged between the outer sheath layers 2; the wrapping layer 3 is made of polyester material.

[0028] The diameter of the wrapping layer 3 is 2.4 mm, the thickness of the outer sheath layer 2 is 1.1 mm, and the thickness of the insulating layer 12 is 0.6 mm. The insulating layer 12 and the outer sheath layer 2 are all made of TPST; the TPST includes TPE, sulfluramid, and pyrethroids; the mass ratio of the TPE, sulfluramid, and pyrethroids is 100:1: 1. The surface of the conductor 11 is plated with a tin layer, and the conductor 11 is GB / T3956 with a cross section of 0.5mm 2 The sixth type of structural conductor. The cable can work normally at the working environment temperature of -50°C to 105°...

Embodiment 2

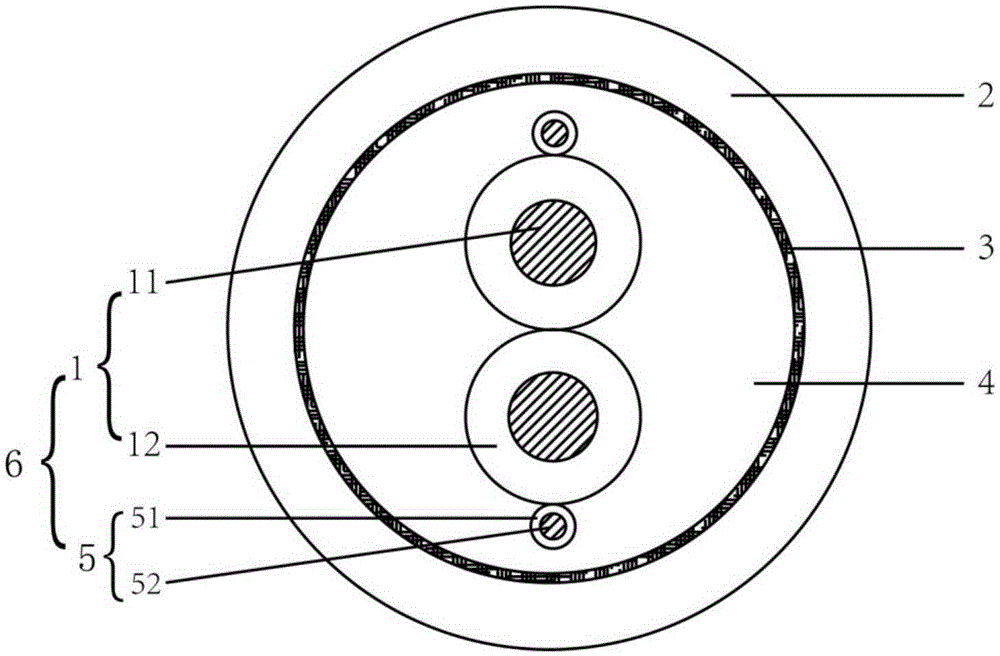

[0030] Such as figure 2 A boarding bridge cable shown includes two wires 1 , each wire 1 includes a conductor 11 and an insulating layer 12 covering the conductor 11 . Each wire 1 is wound with a monitoring wire core 5 , and the monitoring wire core 5 includes a monitoring wire core conductor 52 and a monitoring wire core insulating layer 51 tightly binding the monitoring wire core conductor 52 . The two wires 1 are intertwined, the wires 1 and the monitor wire core 5 form a wire layer 6 , and an inner sheath layer 4 is tightly bound on the wire layer 6 . The inner sheath layer 4 is tightly bound around the outer sheath layer 3 , and the outer sheath layer 2 is tightly bound around the outer sheath layer 3 .

[0031] The length ratio of the monitoring wire core 5 to the wire 1 is 1.1:1. The wrapping layer 3 is made of aramid fiber material. The diameter of the wrapping layer 3 is 48 mm, the thickness of the outer sheath layer 2 is 2.7 mm, and the thickness of the insulatin...

Embodiment 3

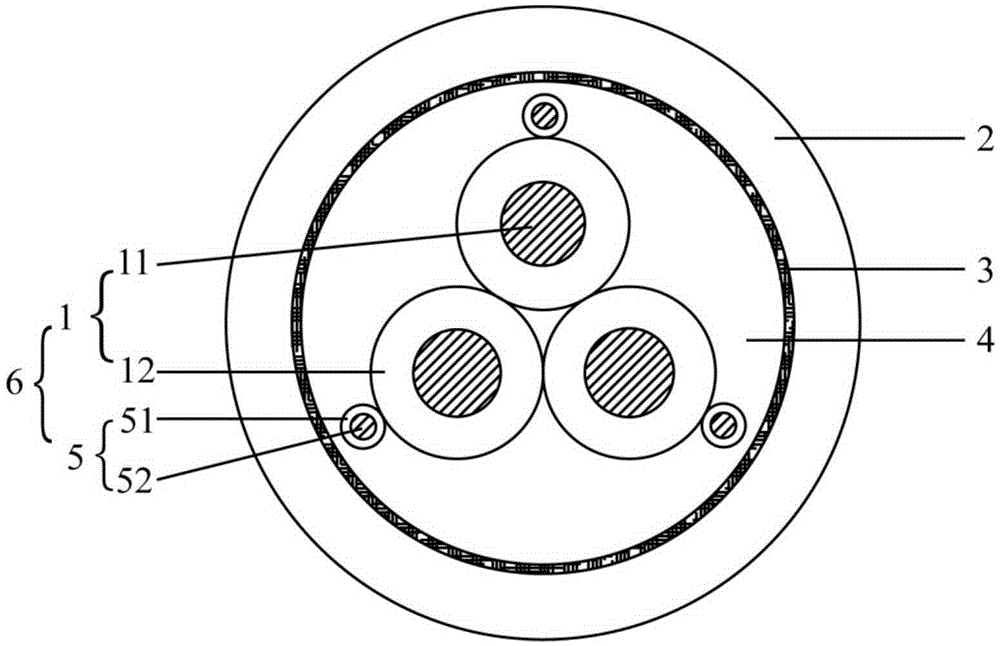

[0033] Such as image 3 A boarding bridge cable shown includes three wires 1 , each wire 1 includes a conductor 11 and an insulating layer 12 covering the conductor 11 . Each wire 1 is wound with a monitoring wire core 5 , and the monitoring wire core 5 includes a monitoring wire core conductor 52 and a monitoring wire core insulating layer 51 tightly binding the monitoring wire core conductor 52 . The three wires 1 are intertwined, the wires 1 and the monitoring wire core 5 form a wire layer 6 , and an inner sheath layer 4 is tightly bound outside the wire layer 6 . The inner sheath layer 4 is tightly bound around the outer sheath layer 3 , and the outer sheath layer 2 is tightly bound around the outer sheath layer 3 .

[0034] The length ratio of the monitoring wire core 5 to the wire 1 is 1.2:1. The wrapping layer 3 is made of aramid fiber material. The diameter of the wrapping layer 3 is 13.3 mm, the thickness of the outer sheath layer 2 is 1.5 mm, and the thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com