Track automatic locking press-board device

An automatic locking and pressing plate technology, applied in the direction of tracks, roads, fixed rails, etc., can solve the problems of lack of buffering and pressing, safety accidents, and high maintenance costs, so as to solve the problem of rail gnawing and pressing plate loosening and reduce accidents. The effect of generating and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

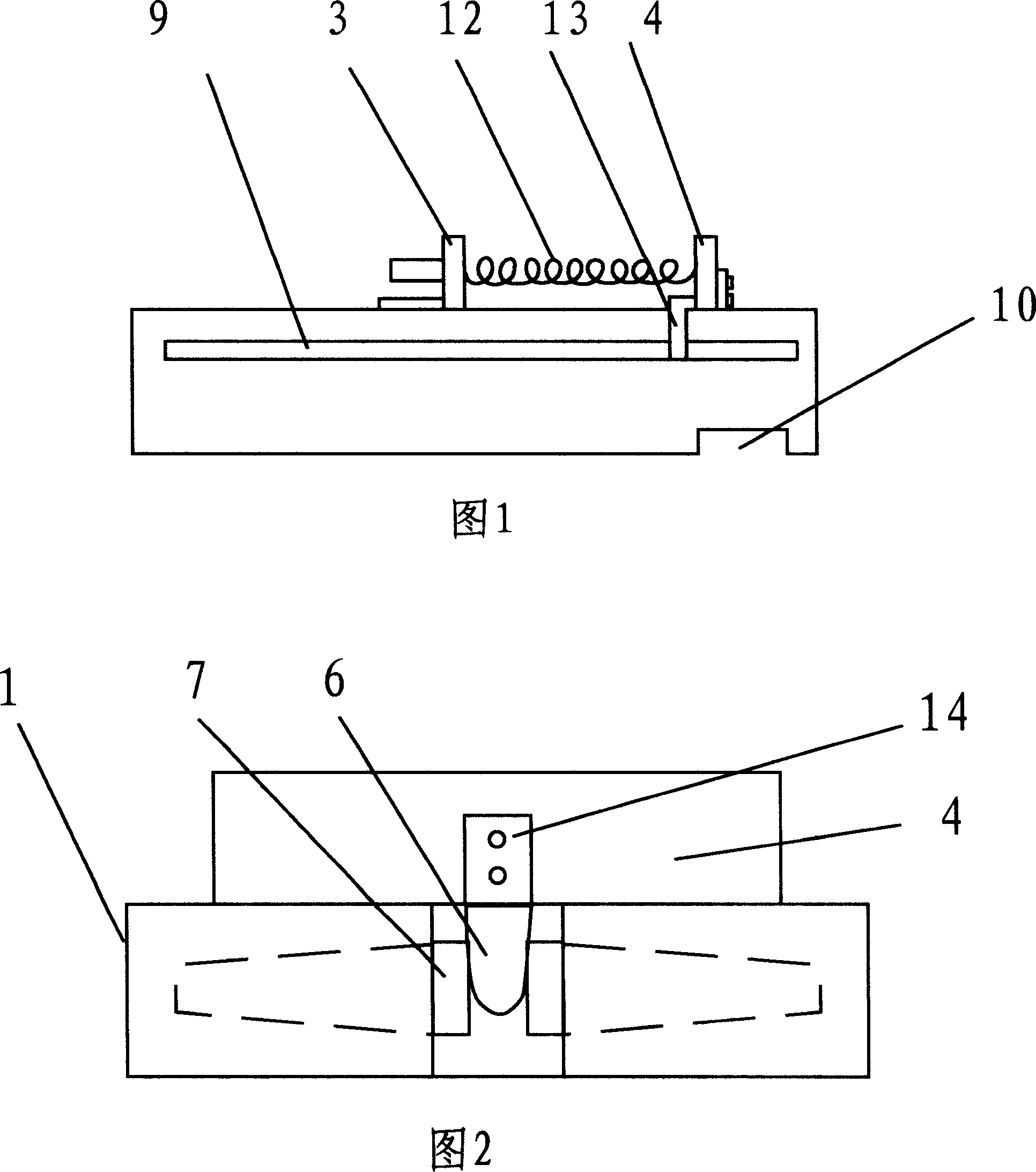

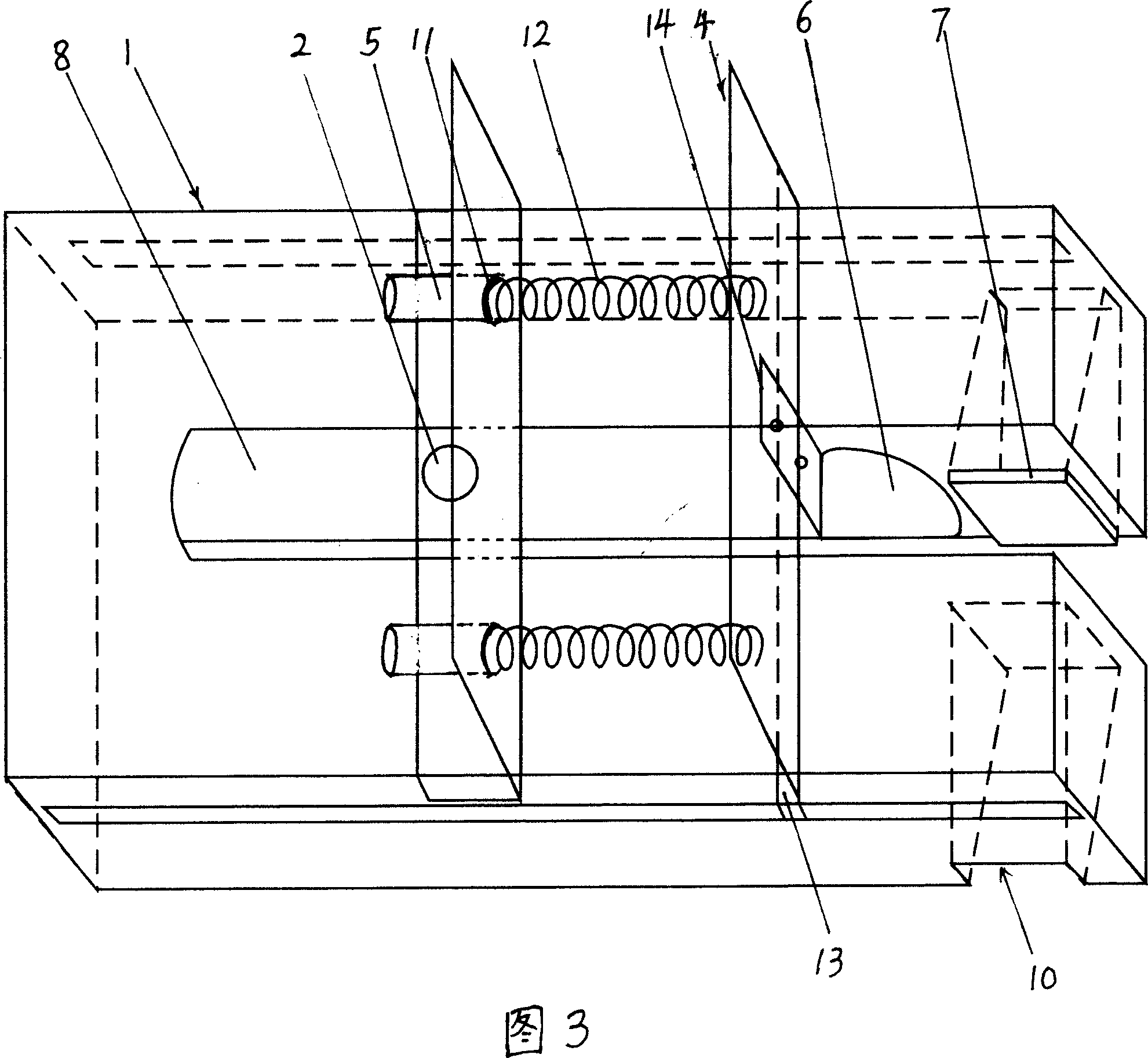

[0011] The track automatic locking pressure plate device includes a pressure plate 1, a fixing bolt 2 and an automatic positioning and locking mechanism. The pressure plate 1 is fixed on the sleeper through the fixing bolt 2. The automatic positioning and locking mechanism includes a spring fixed adjustment plate 3, a moving slide plate 4. Two spring positioning wire tubes 5, conical top block 6, and two locking wedge irons 7. The middle part of the pressure plate 1 is provided with a long opening 8 from the front end to the rear, and the two sides of the pressure plate are respectively provided with guides horizontally. The groove 9 and the bottom surface on both sides of the front end of the pressing plate 1 are respectively provided with locking grooves 10. The two locking wedge irons 7 are wedge-shaped with the upper end facing downward, and are arranged in the locking groove 10 and are adapted to the shape of the locking groove 10. , the spring fixed adjustment plate 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com