High-pressure-resistant wear-resisting contact type reciprocation sealing with washing ring

A high-pressure and wear-resistant technology, which is applied to parts of pumping devices for elastic fluids, variable displacement pump parts, machines/engines, etc., can solve the problems of easy failure of gland side packing, failure of solid particle wear, Problems such as uneven force distribution can avoid the failure of gland side packing, uniform contact stress and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

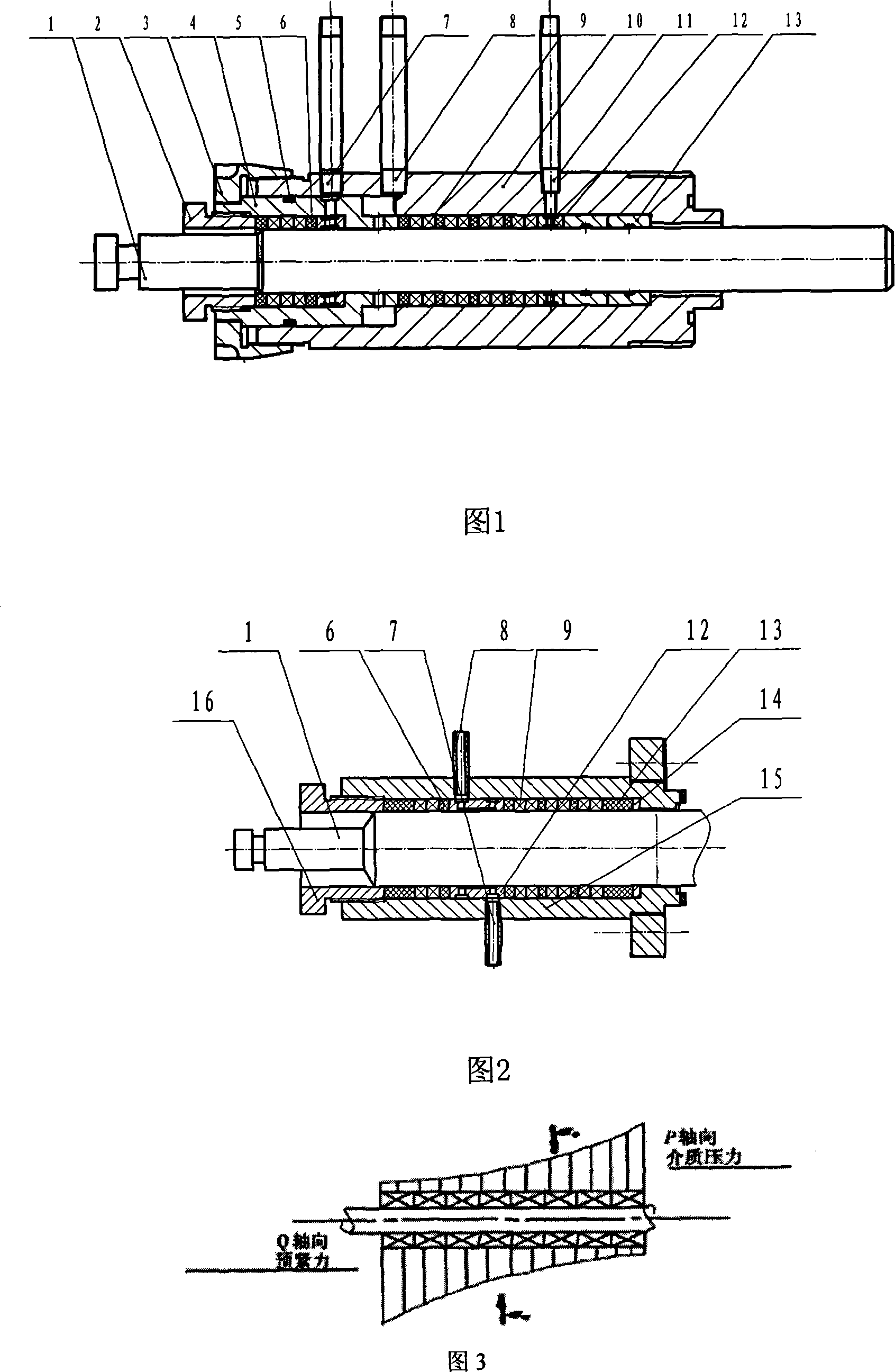

[0012] The sealing structure of the present invention is used as an intermediate prototype for the study of improving the sealing life of a reciprocating special pump for coal liquefaction. As shown in Figure 1, it is composed of a sleeve gap seal near the cylinder side, a main packing seal and a secondary packing seal near the atmosphere side. Composed in series, the front end of the main stuffing box 10 (that is, near the cylinder side) is equipped with two grooved guide sleeves 13, a flushing ring 12, a high-pressure flushing liquid inlet joint 11, two packings 9 and a backing ring 6 One group, four groups are housed in the main stuffing box, and the auxiliary stuffing box 4 is also the main stuffing gland at the same time. In the auxiliary stuffing box 4, a flushing ring 12 is installed, and a backing ring 6 is added on both sides of the three packings 9, and then it is compressed by the auxiliary stuffing gland 2, and the auxiliary stuffing box 4 is compressed by the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com