Static-pressure supporting spherical self-aligning bearing seat

A self-aligning bearing and hydrostatic support technology, applied in the direction of bearing components, shafts and bearings, and rigid supports of bearing components, can solve the problems of large sliding friction resistance, insufficient lubrication, and unsatisfactory self-aligning effect, and achieve guaranteed Alignment effect, the effect of reducing sliding frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

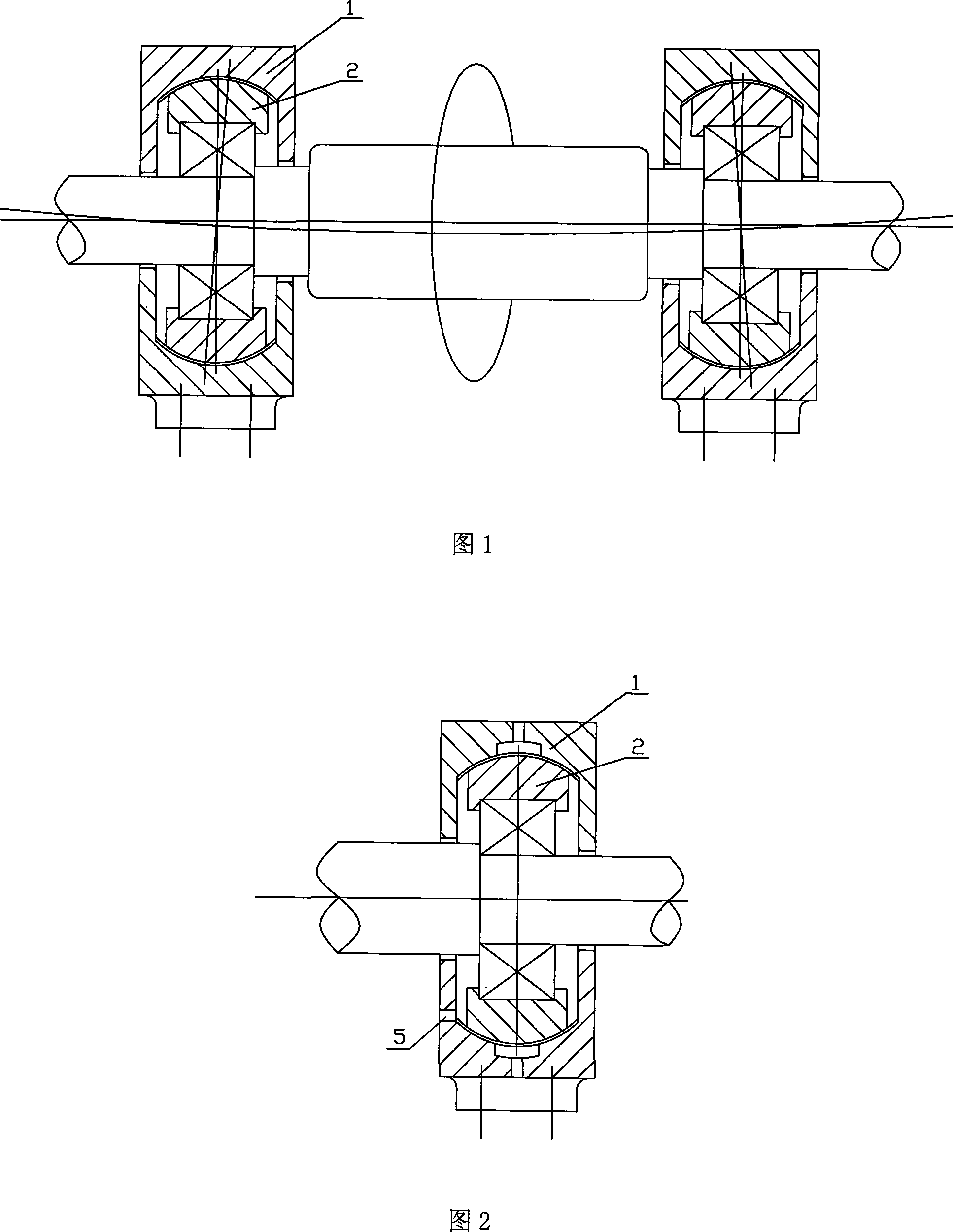

[0019] As shown in Figures 2 and 3, a spherical self-aligning bearing seat with static pressure support includes a fixed seat 1 and a moving body 2, and three oil chambers are arranged on the upper and lower concave spherical surfaces within the range of 180° of the fixed seat 1. 3. The oil chamber 3 is connected with the oil passage 4 connected to the external oil source, and the pressure oil is provided by the external oil source, forming a complete oil film between the fixed seat 1 and the moving body 2, and the bearing seats can be flexible when they work in groups Automatic centering. An oil return circuit 5 is arranged in the fixed seat, and the oil return circuit 5 is connected to the oil source through a pipeline connected thereto, so that the oil flowing out from the gap between the fixed seat and the moving body returns to the oil source through the oil return circuit.

[0020] The concave spherical surface of the seat 1 is a 360° annular spherical surface.

Embodiment 2

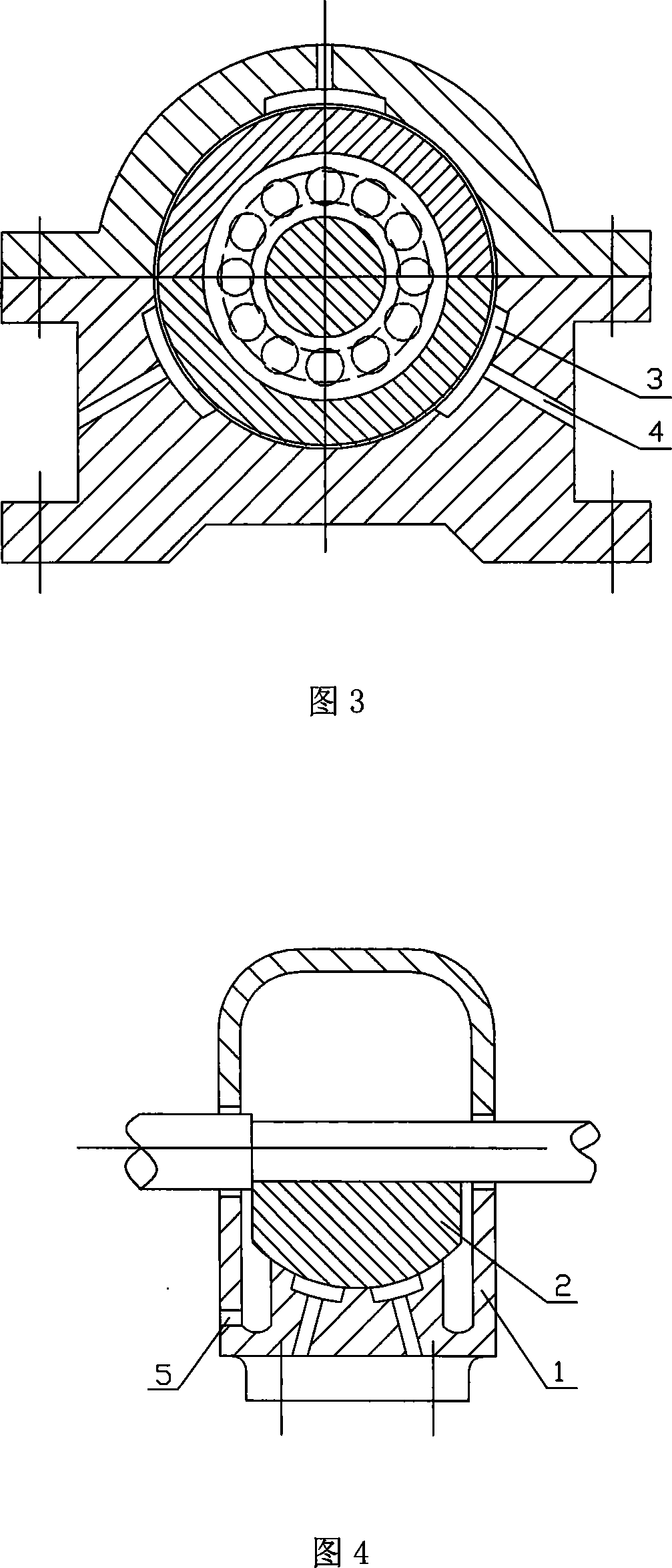

[0022] As shown in Figures 4 and 5, a spherical self-aligning bearing seat with static pressure support includes a fixed seat 1 and a moving body 2, and a plurality of oil chambers 3 are arranged on the concave spherical surface within 180° of the fixed seat 1. The cavity 3 is connected with an oil passage 4 connected to an external oil source, and the pressure oil is provided by the external oil source, forming a complete oil film between the fixed seat 1 and the moving body 2, and the flexible and automatic centering can be realized when the bearing seats work in groups . An oil return circuit 5 is arranged in the fixed seat, and the oil return circuit 5 is connected with the pipeline.

[0023] The concave spherical surface of the seat 1 is a partial annular spherical surface of 180°.

Embodiment 3

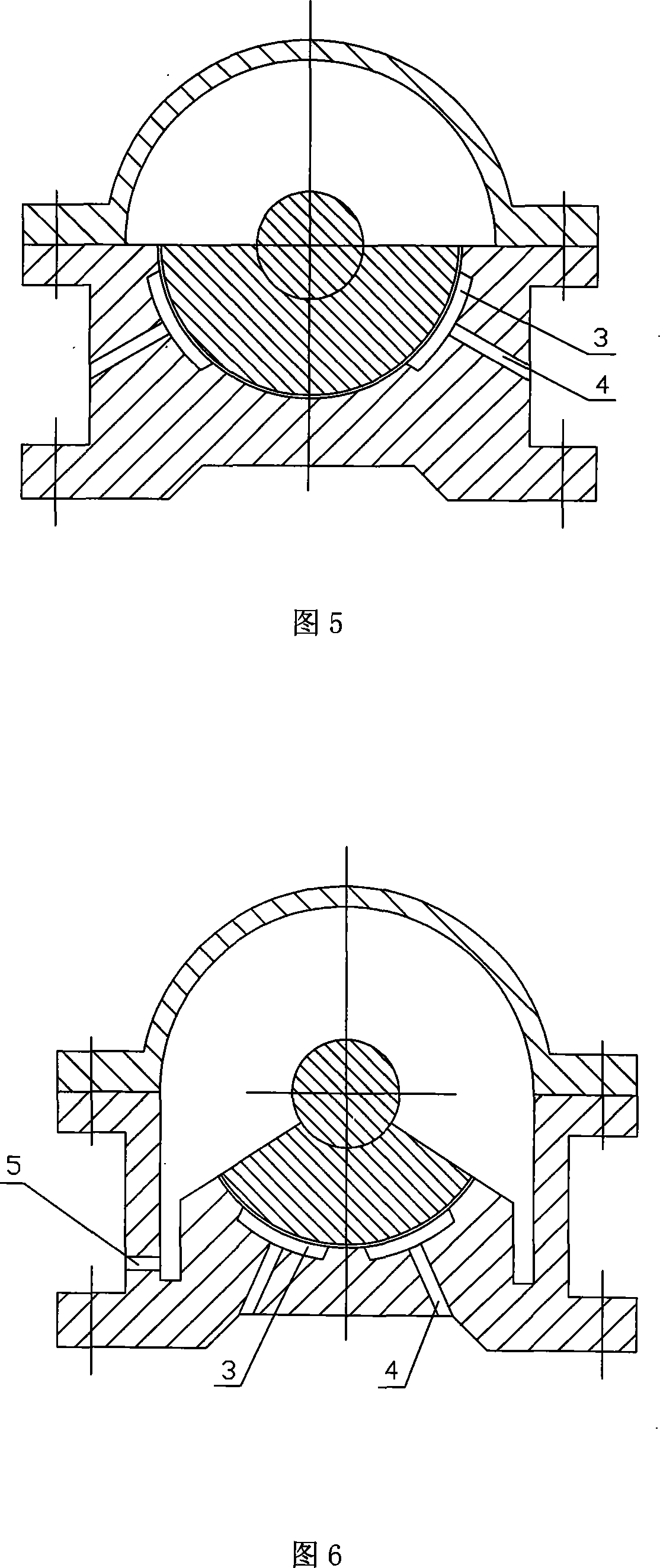

[0025] As shown in Figure 6, a spherical self-aligning bearing seat with static pressure support includes a fixed seat 1 and a moving body 2, and a plurality of oil chambers 3 are arranged on the concave spherical surface within the range of 180° less than the fixed seat 1. 3 is connected with an oil passage 4 connected to an external oil source, and the pressure oil is provided by the external oil source to form a complete oil film between the fixed seat 1 and the moving body 2, and the bearing seats can realize flexible and automatic centering when they work in groups. An oil return circuit 5 is arranged in the fixed seat, and the oil return circuit 5 is connected with the pipeline.

[0026] The concave spherical surface of the seat 1 is a partial annular spherical surface less than 180°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com