Multi-connecting board bad-product detecting device and method

A detection device and detection method technology, which is applied in the field of multiple boards, can solve the problems of increasing production capacity, unsustainable component placement operations, waste, etc., and achieve the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

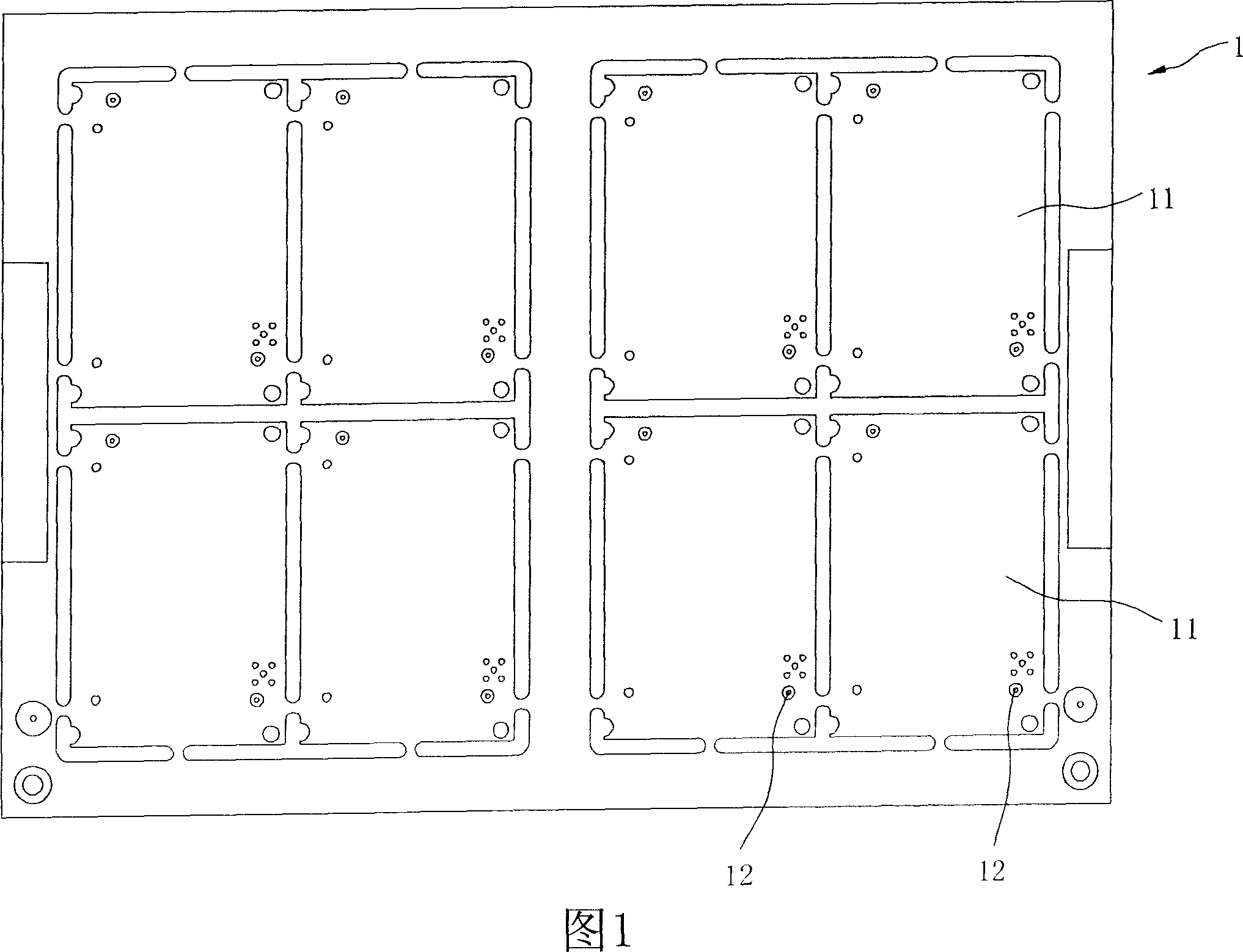

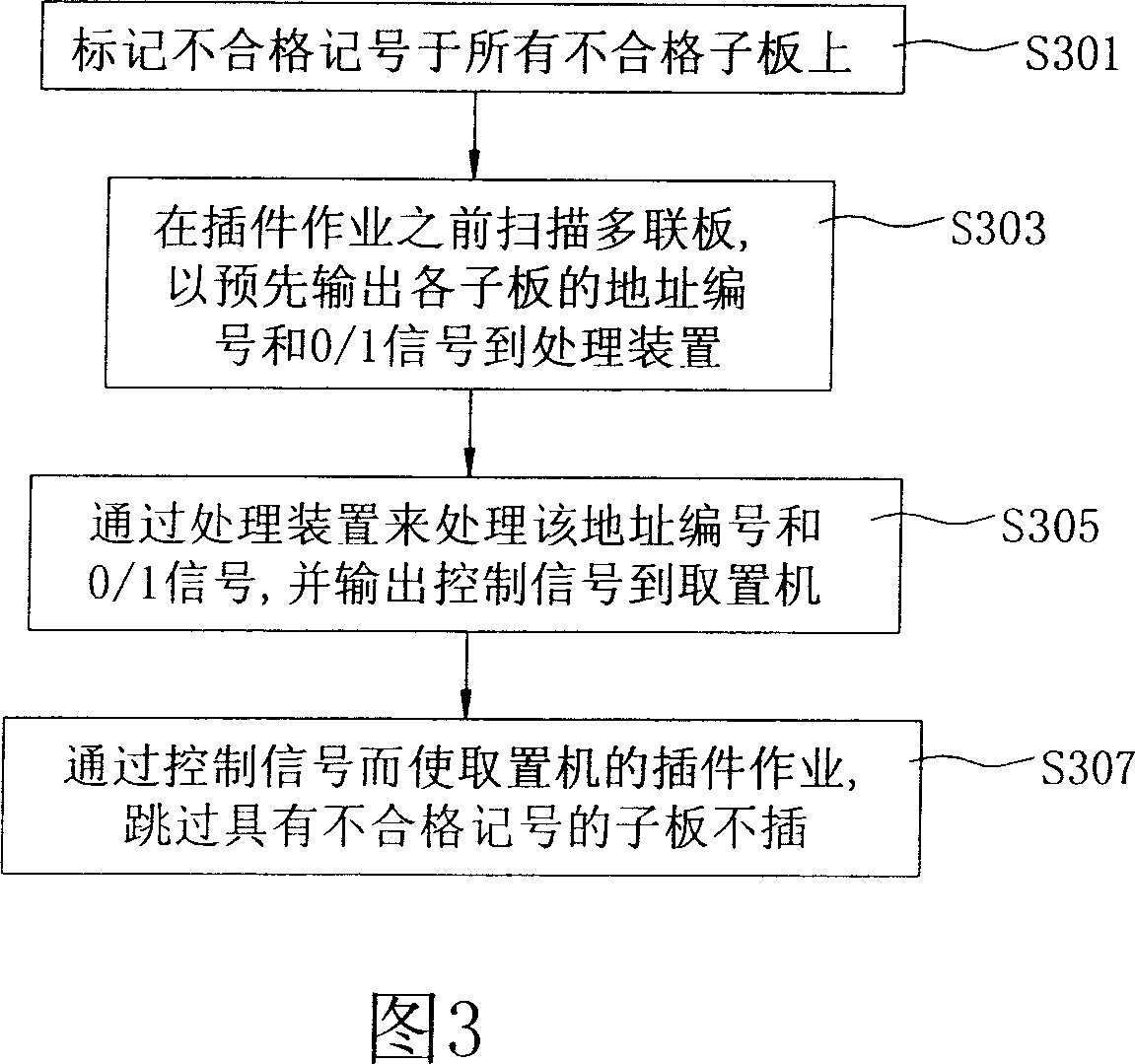

[0045] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

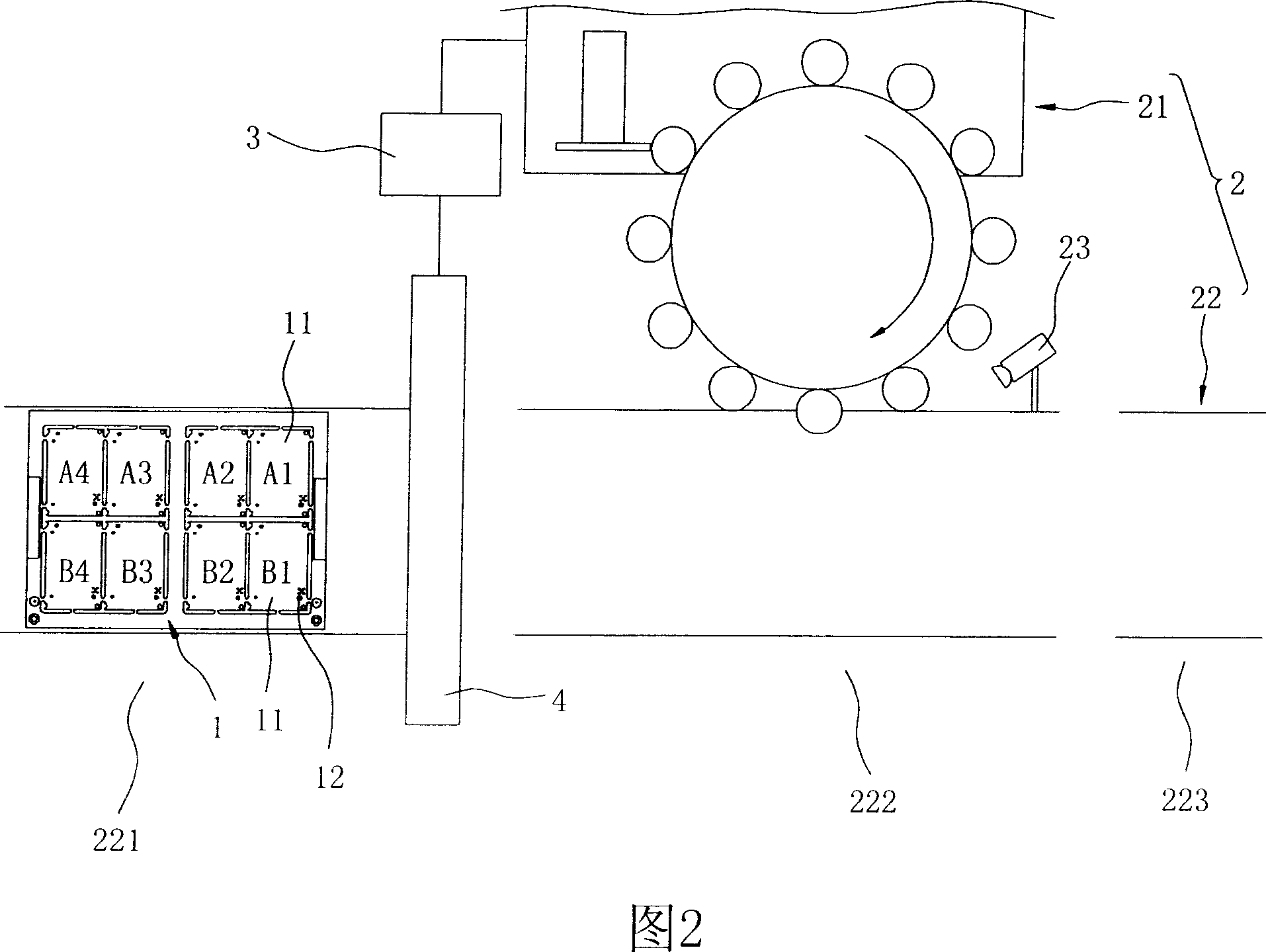

[0046] Please refer to FIG. 2 and FIG. 3 , the present invention provides a first embodiment of a multi-board defective detection device and method.

[0047]As shown in FIG. 2 , the detection device of the first embodiment is applied to a component placement device 2 . The device 2 includes a pick-and-place machine 21 and a conveying member 22, the pick-and-place machine 21 can be a rotary (Rotary, as shown) or a gantry (Gantry, not shown); the conveying member 22 can be each The component that can be conveyed, or the conveyor belt as shown in the figure, the conveying component 22 has a preparation area 221, a completion area 223 and a placement area 222 between the two areas, and the pick-and-place machine 21 is arranged in the placement area 222 on. The conveying member 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com