Pneumatic tyre with improved bead structure

A technology of pneumatic tire and carcass structure, applied to the reinforcement layer, tire parts, tires and other directions of pneumatic tires, can solve the problem that the stability of the geometric structure of the bead cannot be guaranteed, and achieve increased geometric structure stability, The effect of reducing time and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0124] Two types of tires (Tire A and Tire B) were manufactured, the size of which was 315 / 80 R22.5.

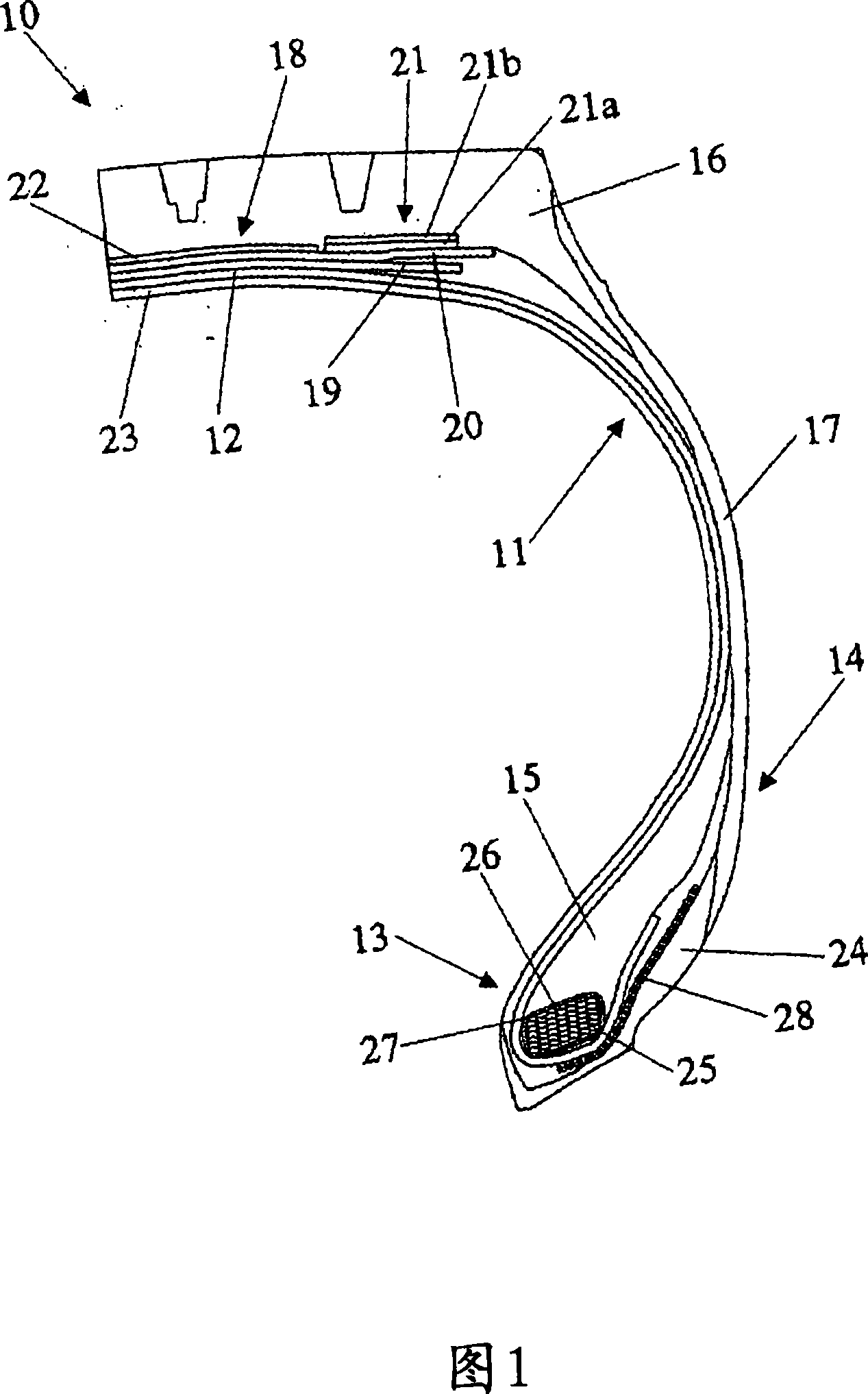

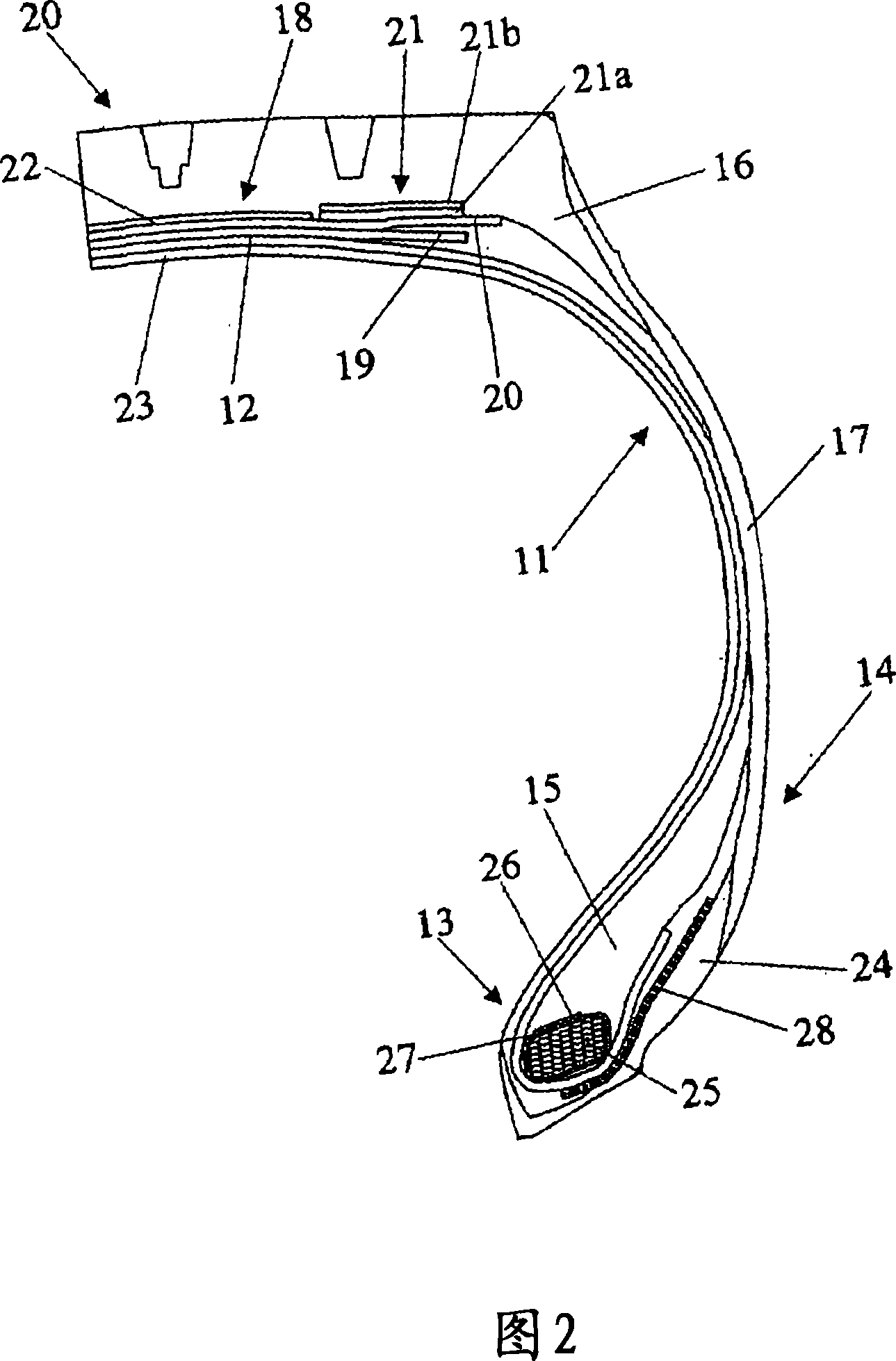

[0125] Tires A and B have the same structural elements, namely the same carcass (a carcass ply), two intersecting belt layers, two transverse reinforcing strips (zero degree reinforcing strips, which are positioned at the radially outer, and consists of two radially overlapping layers, as shown in Figures 1 and 2), a buffer layer (which overlaps radially on the radially outer belt layer and is located between the transverse reinforcing strips), likewise tread belt.

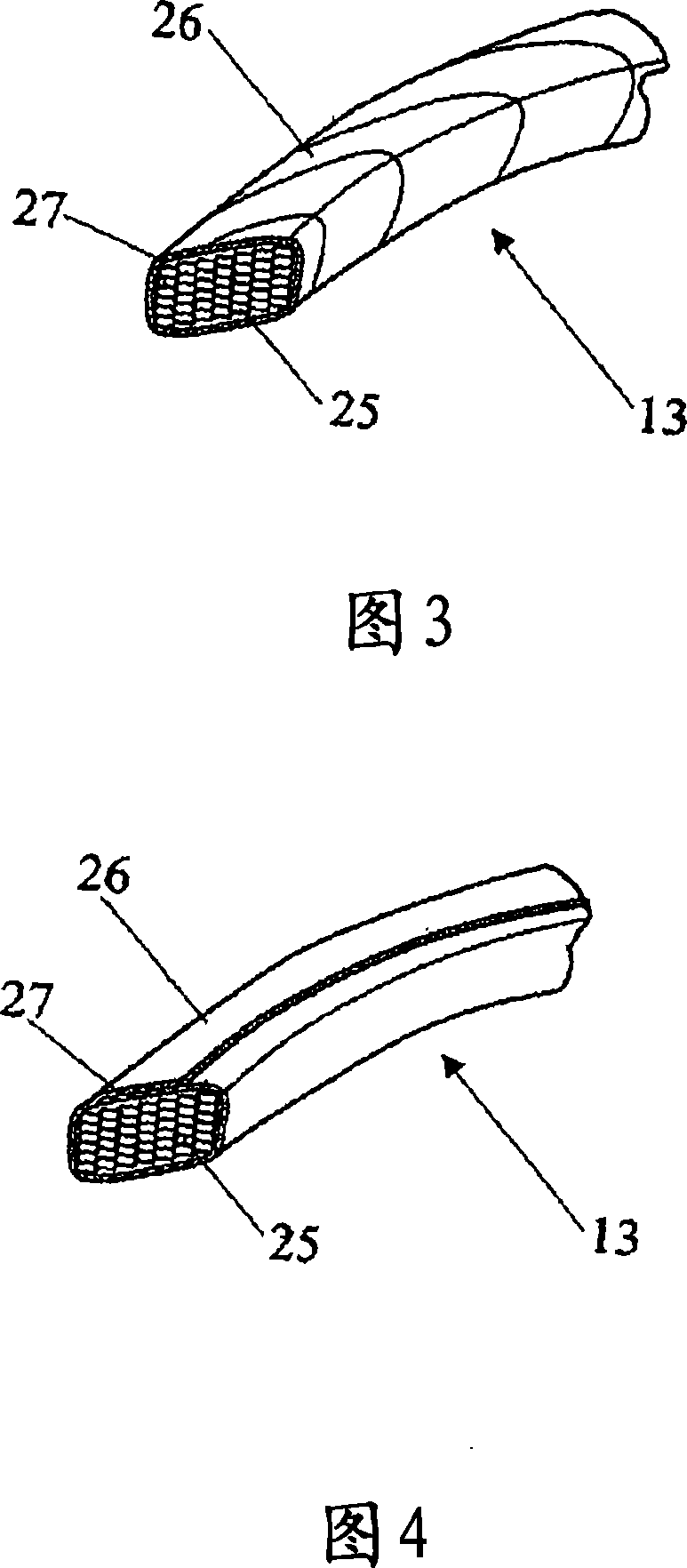

[0126] Tire A (a tire according to the invention) also comprises a bead core as shown in FIG. The bead core is obtained by forming seven axially adjacent columns, each column consisting of six radially overlapping coils. According to the invention, the bead core also comprises retaining means applied in the form of a sheet by folding the sheet around the peripheral contour of a plurality of coils constituted by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com