Non-positive fit elastic rail connection device for track systems

A technology of fixing devices and elastic rails, applied in the direction of rails, fixed rails, roads, etc., can solve the problem of increasing bolt load and achieve the effect of small structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

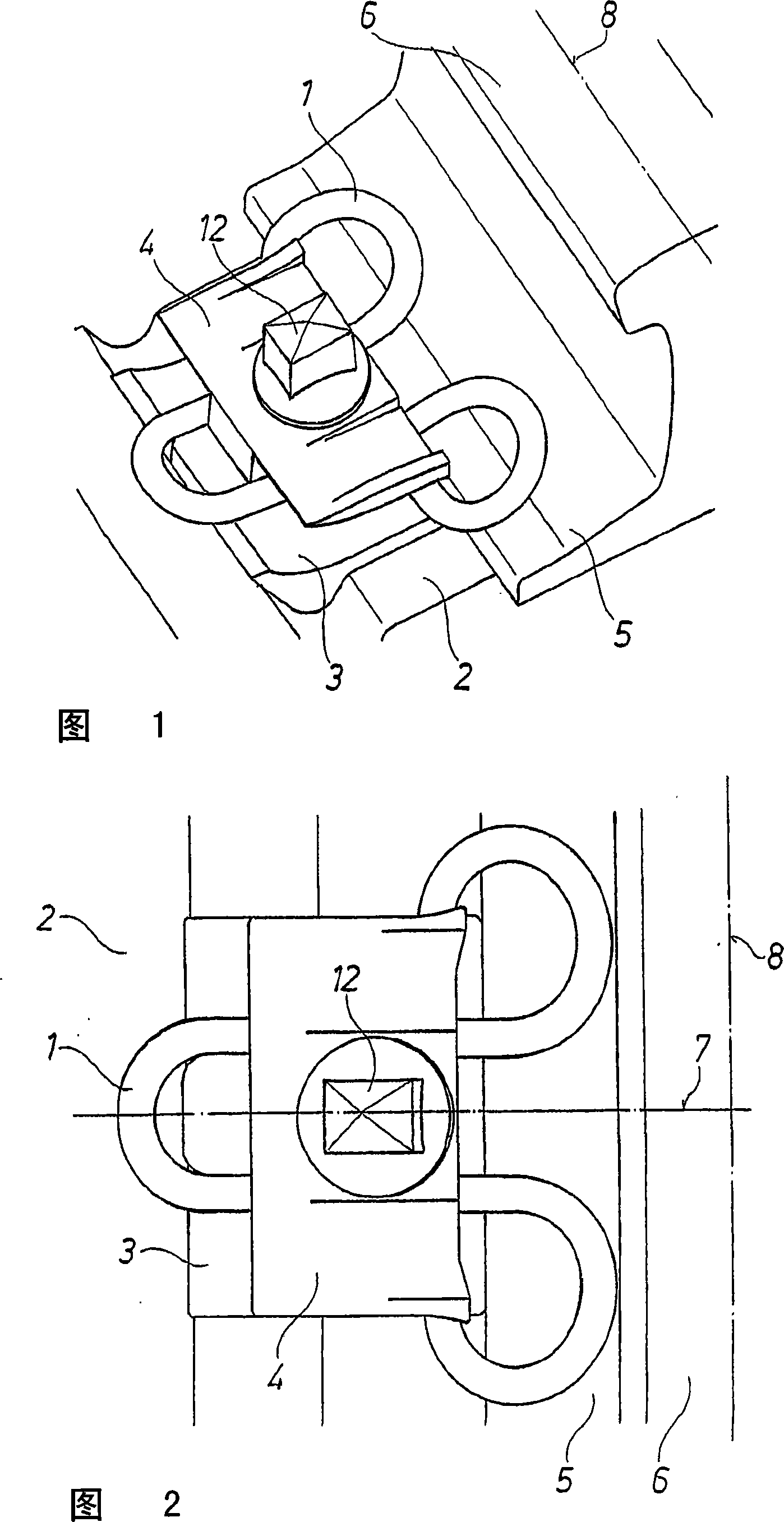

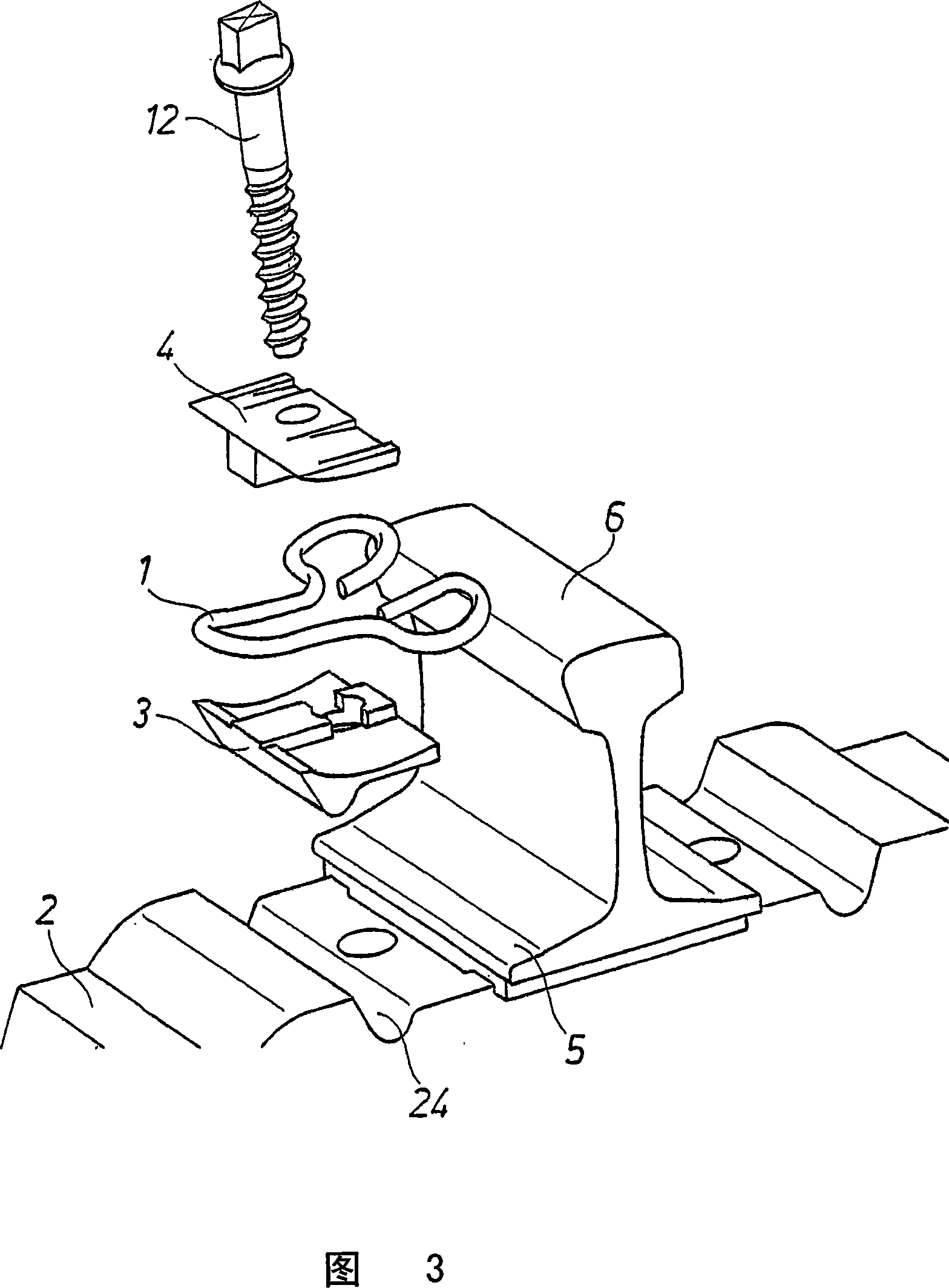

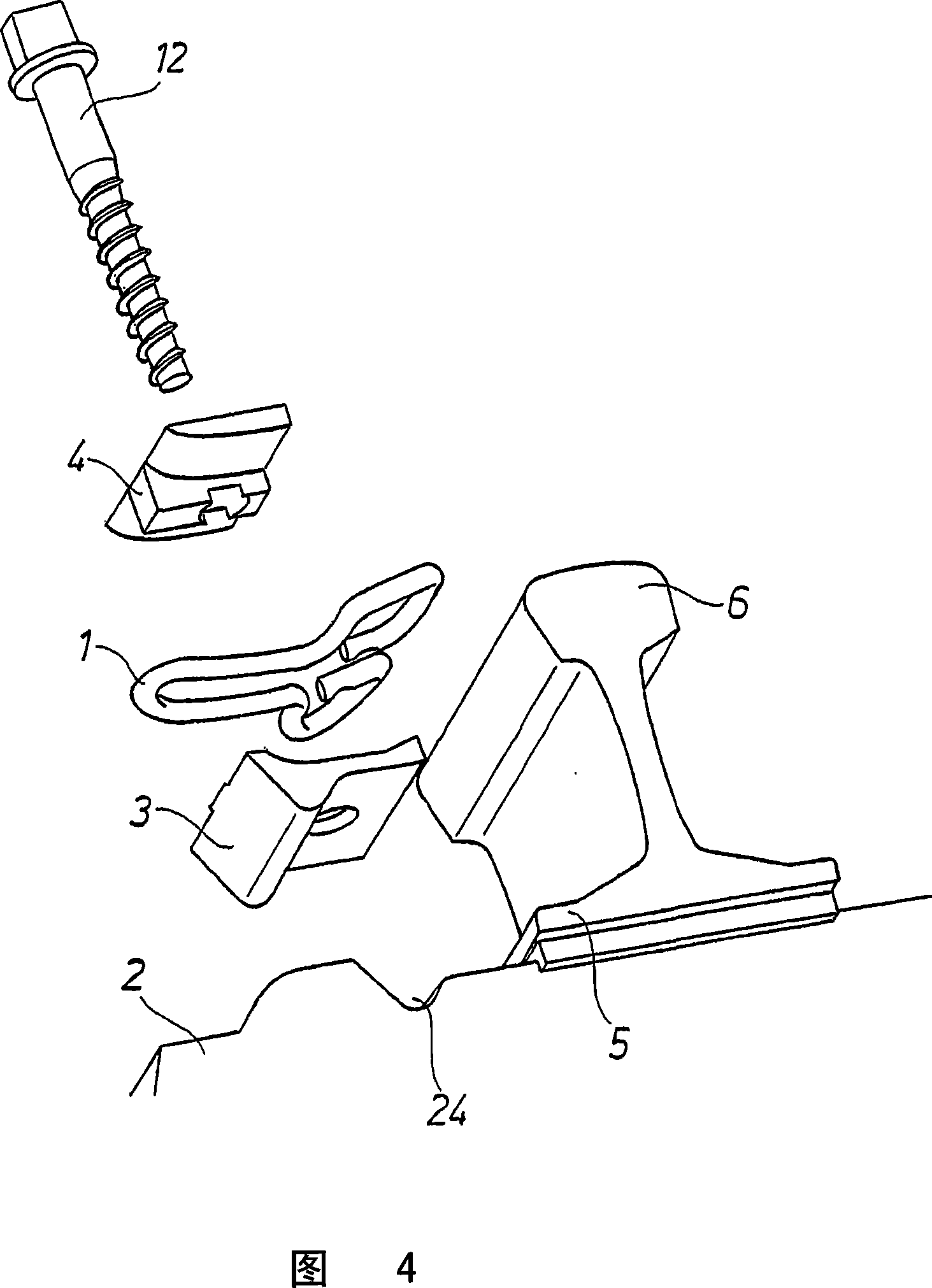

[0079] The basic structure of a non-positive connection elastic rail fastening for rail installations can be seen in FIGS. 1 to 4 . The track 6 must be fastened to the sleeper 2 or the track pad (see Figure 23). For this purpose, recesses 24 in the sleeper 2 are provided on the sleeper 2 , the shape of which corresponds to the protrusion of the support plate 3 resting on said sleeper 2 . The recesses 24 can be designed accordingly in the form of known angled guides or in other ways. The plate-shaped fastening anchor 4 is fastened to the support plate 3 or to the sleeper 2 by means of the sleeper bolt 12 . Arranged between the fastening anchor 4 and the support plate 3 is a clamping part 1 which, in its mounted state, exerts pressure on the rail foot 5 and thus fixes the rail 6 in the desired position.

[0080] As can be seen in FIG. 2 , the clamping part 1 is designed symmetrically, wherein the plane of symmetry 7 is arranged vertically and is perpendicular to the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com