Delivery testing method for large hoist engine

A factory test, winch technology, applied in the direction of hoisting device, clockwork mechanism, etc., can solve the problems of high construction difficulty and large investment, and achieve the effect of saving equipment investment and test site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

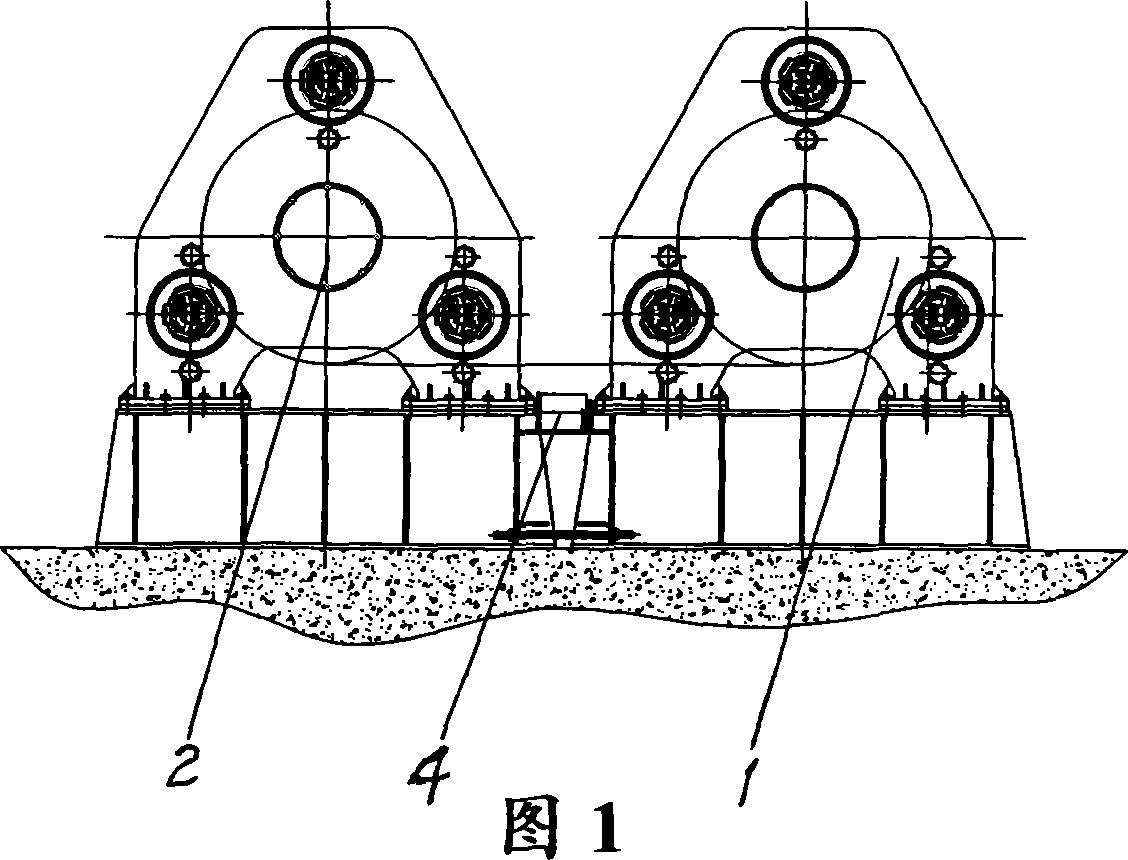

[0020] Referring to Fig. 1 and Fig. 2, according to a factory test method of a large-scale hoist of the present invention, two test hoists are used, one of which is the tested hoist 1 and the other is the loading hoist 2, or two test hoists are used in the test. The hoists alternate with each other. Two identical hoist prototypes are used to facilitate mutual loading during type testing.

[0021] The present invention adopts the following steps to carry out type and factory tests:

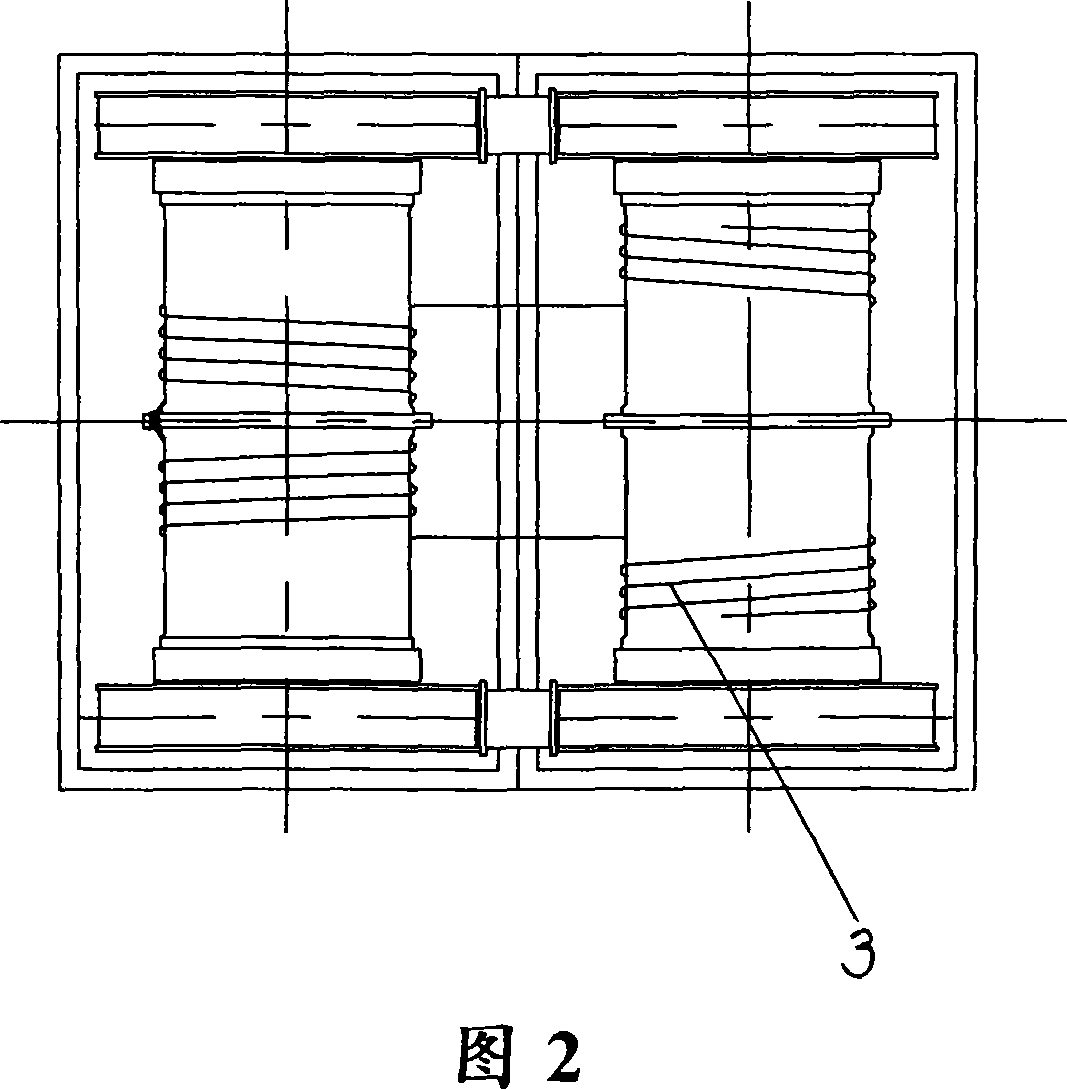

[0022] Place the two test winches face to face and close together, and connect the two drums of the winches with wire rope 3 (as shown in Figure 2), so that the tension of the steel wire rope becomes the internal force of the winch, and the winch does not need to be fixed to the ground.

[0023] An intermediate hydraulic cylinder support device 4 is added between the two test winches, preferably two sets of support devices for the connection between the winches are used to adjust the tension balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com