Method and apparatus for eliminating filament meta-flint in heating fibre beam by radio-frequency

A technology of heating device and fiber bundle, which is applied in the direction of carbon fiber, fiber treatment, fiber chemical characteristics, etc., can solve the problems of different electromotive force induced by single filament, increased end breakage, silk and wool overlap and sparking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

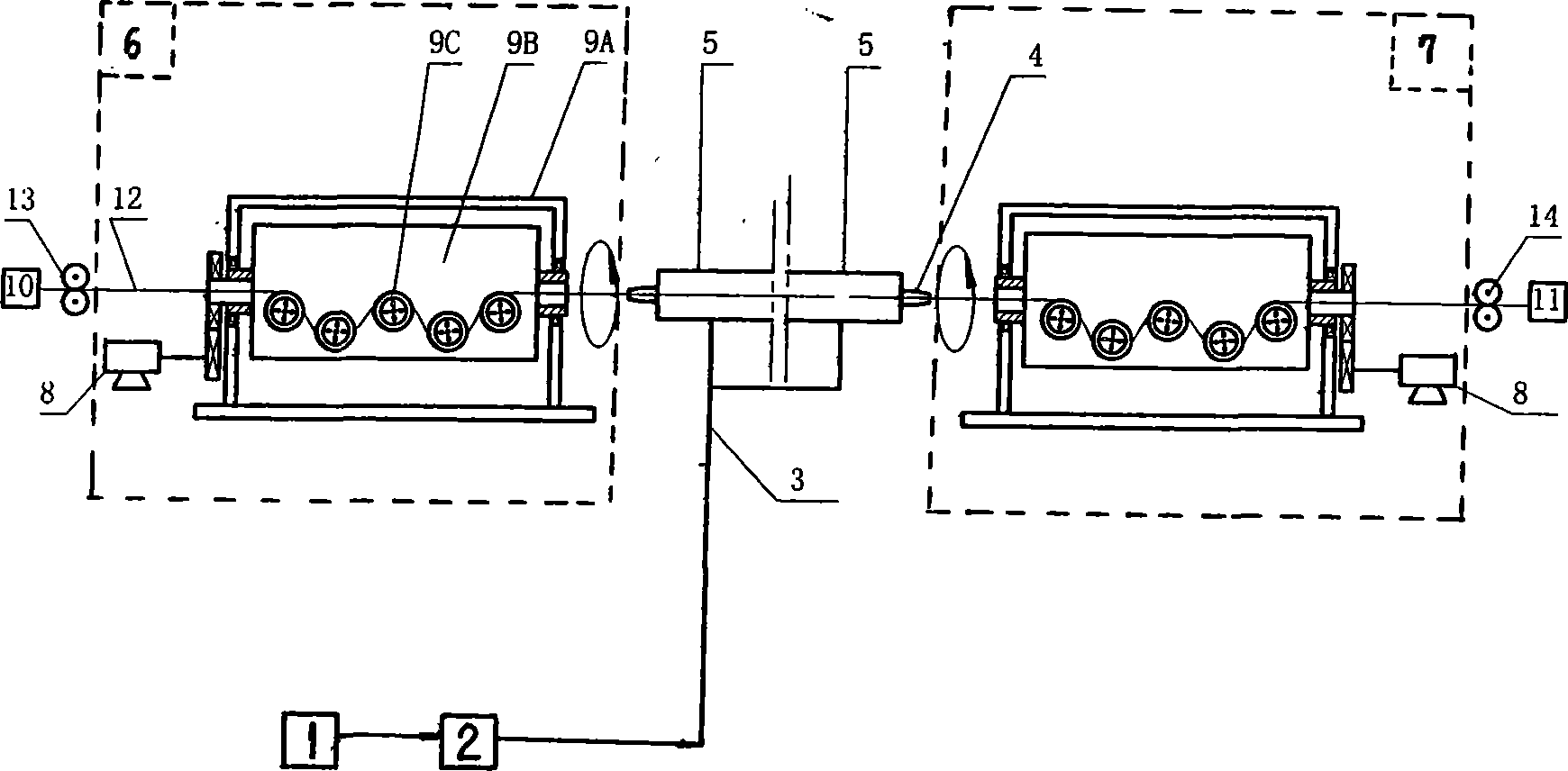

[0012] With reference to the accompanying drawings, it can be seen that the method of eliminating the sparking between monofilaments in the radio frequency method fiber bundle heating is realized through the following steps:

[0013] The radio frequency linear focus heating device used is modified, and after the tow twisting device 6 is set between the wire feeding mechanism 10 and the quartz tube thermal reactor 4, the heated fiber bundle 12 can be thermally reacted when it enters the quartz tube. Twisting treatment is carried out before the reactor 4, so as to effectively prevent sparking phenomenon after entering the quartz tube thermal reactor 4 and reaching the heating zone.

[0014] However, in most applications, the processed product is used to make composite materials. In order to ensure the bonding strength between the composite base material and the fiber generation monofilament, it is more desirable that the bundles are arranged in parallel rather than twisted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com