Elevator button and its manufacture

A button and elevator technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of different processing methods, inability to apply elevator buttons, etc., to achieve the effect of durable and wear-resistant characters, simplified laser engraving operation process, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below.

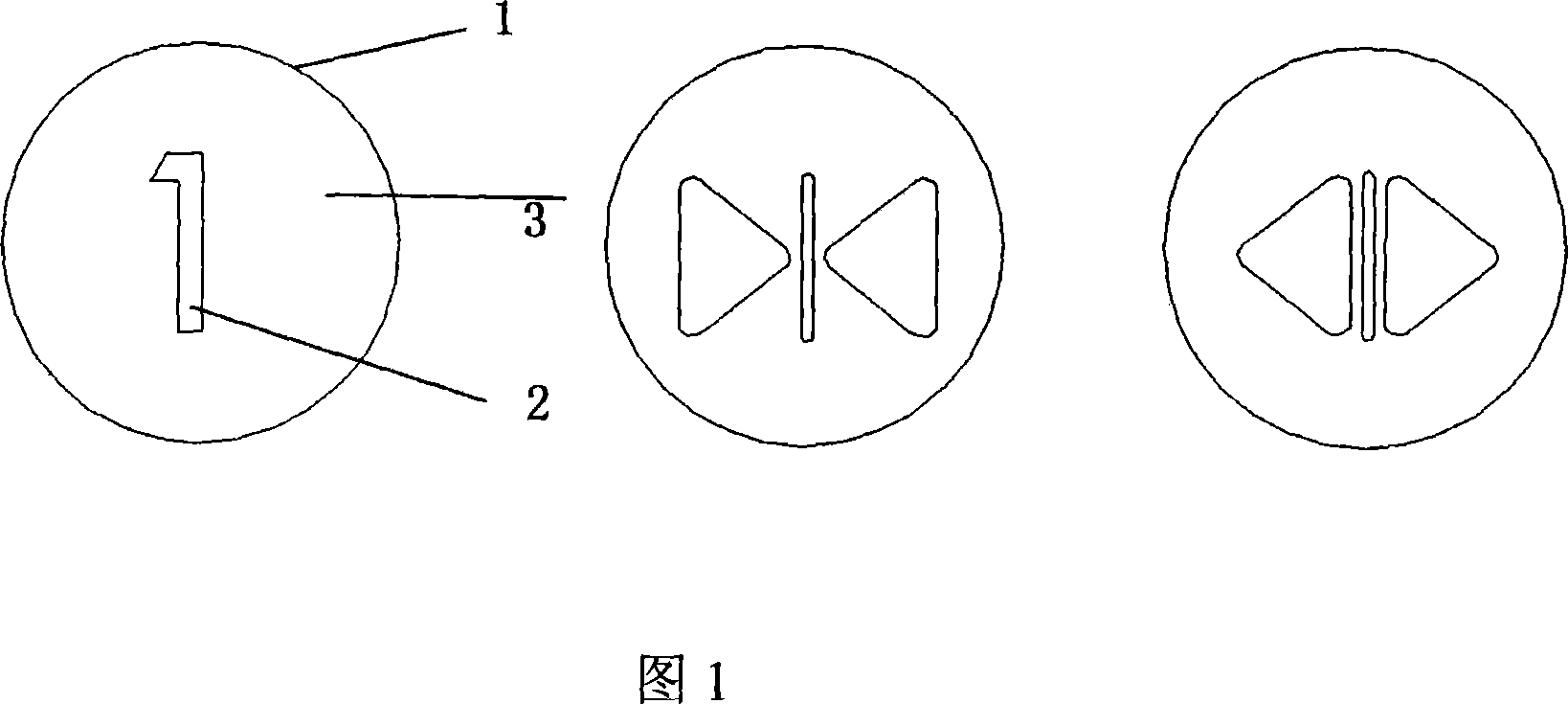

[0020] One embodiment of the preparation method of the elevator button is: first electroplate a layer of electroplating layer 3 on the stainless steel button 1, and the electroplating layer is copper layer, nickel layer, and chromium layer successively from the base material layer, wherein: the thickness of the copper layer is about 20 μm , the thickness of the nickel layer is about 10 μm, and the thickness of the chromium layer is 0.2 μm-1 μm; after the laser beam emitted by the YAG laser is focused, the copper layer, nickel layer and chromium layer of the high-temperature high-temperature electroplating layer generated in the spot area are vaporized, and the stainless steel The surface is partially oxidized, resulting in a dark colored oxide layer. The laser beam emitted by the YAG laser is focused to produce a spot of about 0.05mm, and the main output laser mode is TEM 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com