Tensioning device for spinning machine lower leather collar

A tensioning device and spinning machine technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., to achieve the effects of reducing wrap angle, reducing probability, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

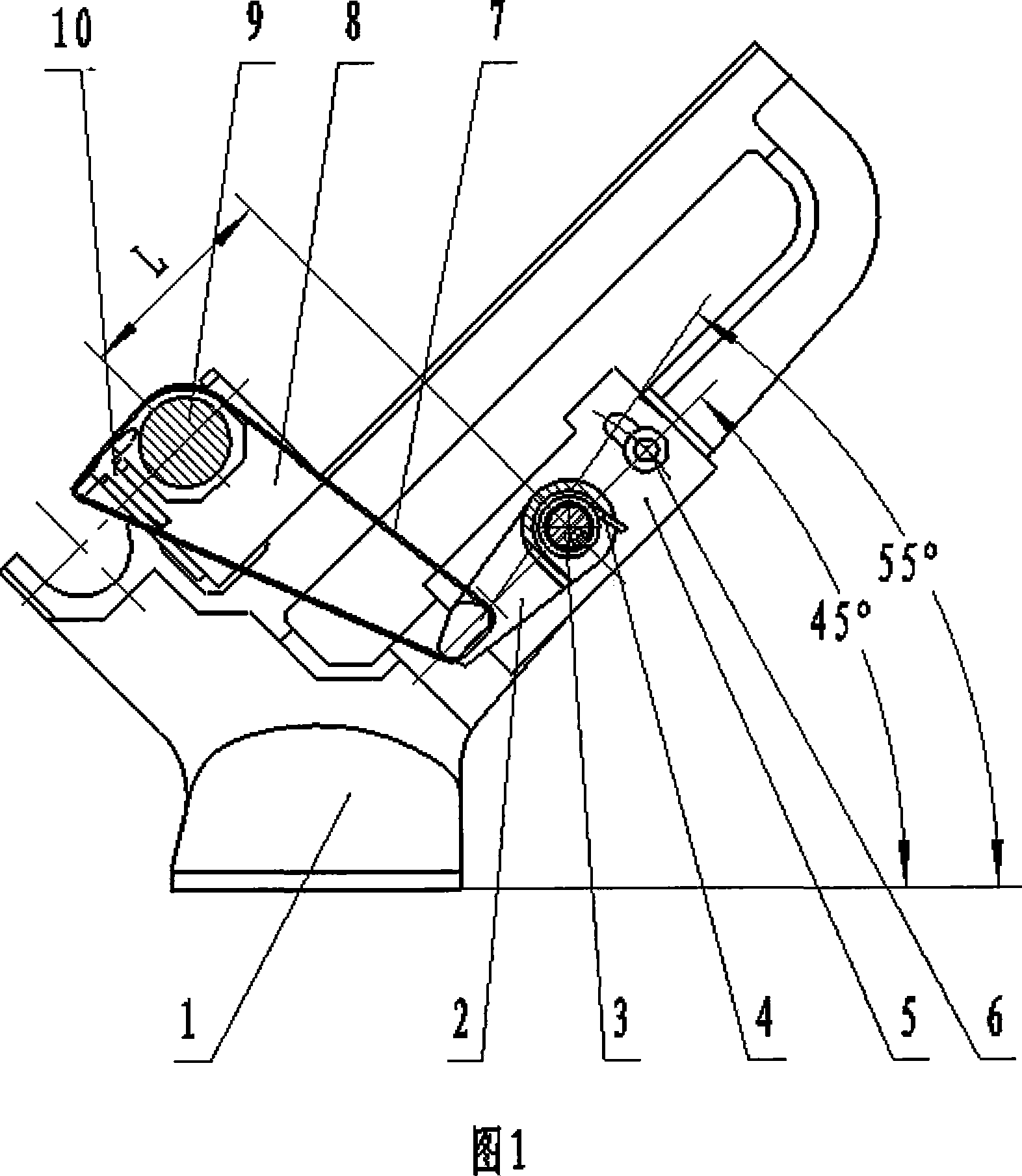

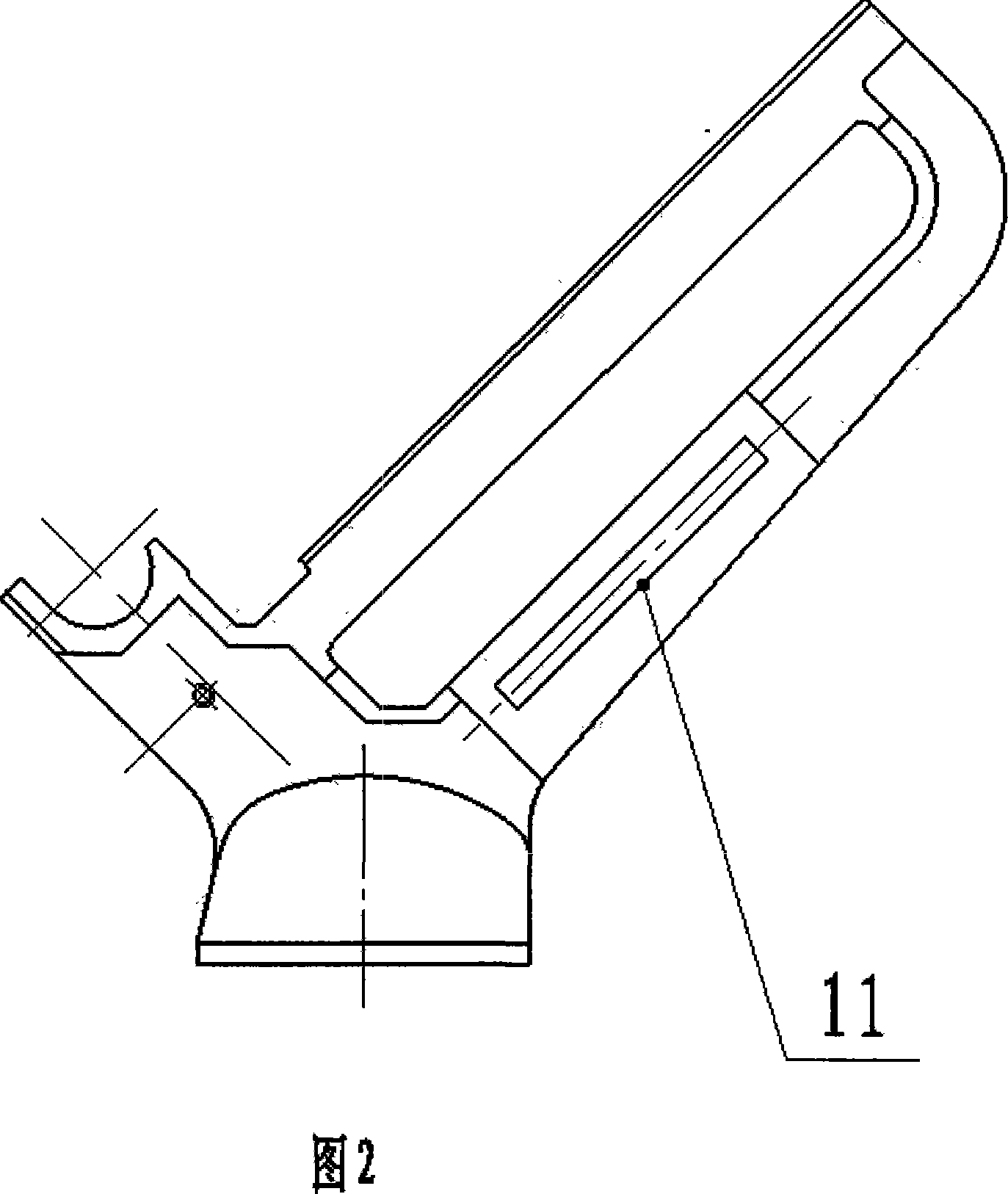

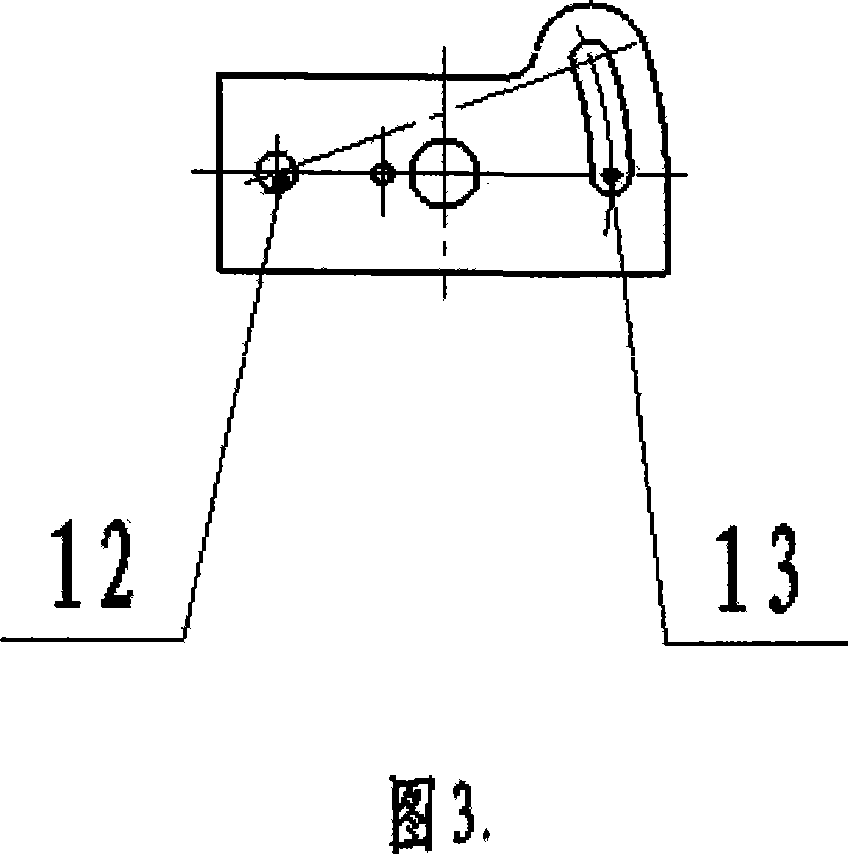

[0009] As shown in Figure 1: the apron tensioning device includes roller seat 1, tension frame 2, tension frame support rod 3, torsion spring 4, tension rod mounting plate 5, screw 6, lower apron 7, middle roller slide seat 8. The middle roller 9, the lower pin 10, the middle roller 9 and the lower pin 10 are arranged on the middle roller slide 8, the middle roller slide 8 is arranged on the roller seat 1, the tension frame 2 connects the tension frame support rod through the torsion spring 4 3 connection, a long hole 11 is arranged on the reinforcing rib of the roller seat 1, a tension rod mounting plate 5 is arranged on the long hole 11, and two screw holes are arranged on the tension rod mounting plate 5, one is a round hole 12, and the other is a round hole 12. It is a long hole 13, and the tension rod mounting plate 5 is arranged on the roller seat 1 through the screw 6. The angle of the tension rod mounting plate 5 on the roller seat 1 is 45 degrees. The frame 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com