Fan and impeller thereof

A technology of fan blades and fans, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., which can solve the problems of poor efficiency, reduce fan load and power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

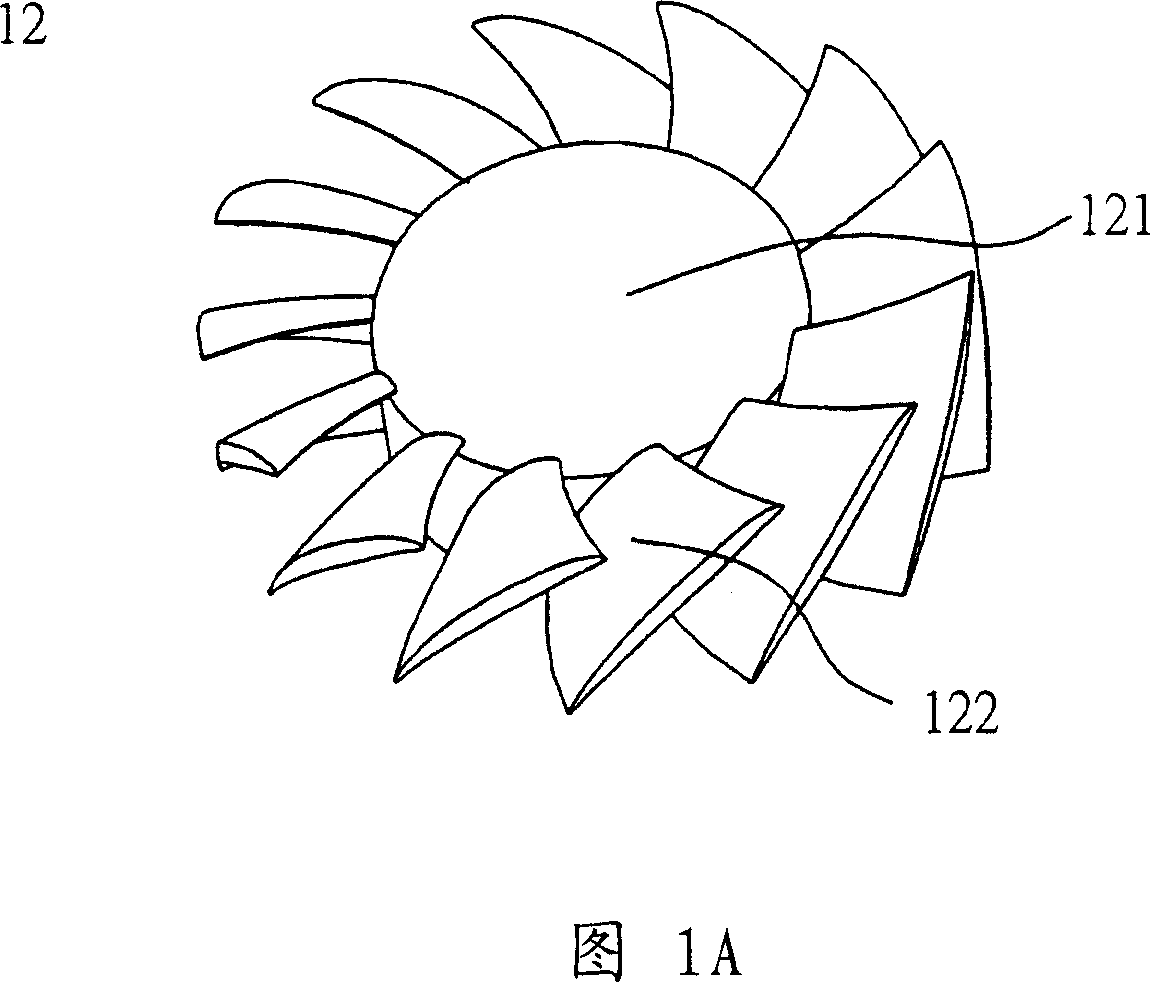

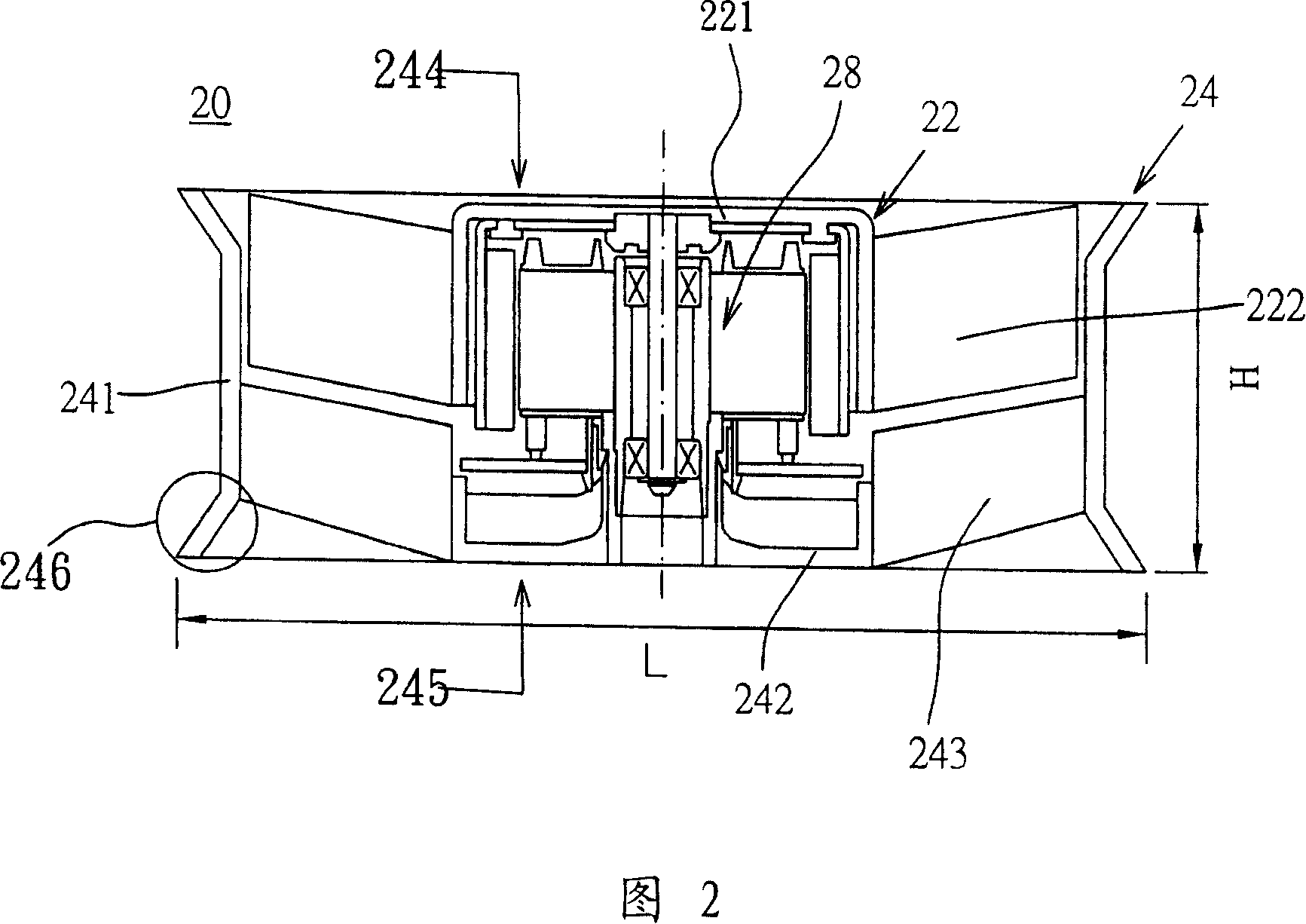

[0026] Please refer to FIG. 2 , which is a schematic cross-sectional view of a fan according to a preferred embodiment of the present invention. The fan 20 of the present invention is, for example, an axial fan, including a fan frame 24 , an impeller 22 , and a motor 28 . The fan frame 24 has a frame body 241 , a base 242 and at least one support member 243 , and the base 242 is connected to the frame body 241 through the support member 243 . The impeller 22 is disposed on the base 242 , and the impeller 22 includes a hub 221 and a plurality of fan blades 222 , and the plurality of fan blades 222 are disposed around the hub 221 . The motor 28 is connected with the impeller 22 and drives the impeller 22 to rotate.

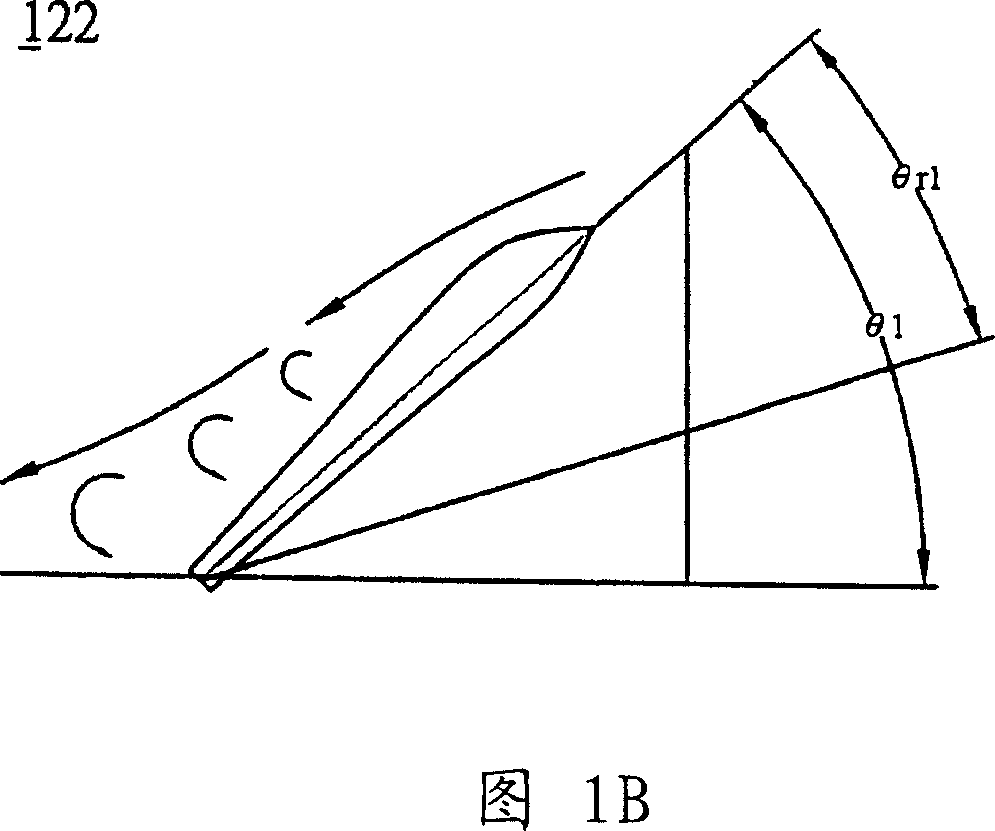

[0027] In order to improve the existing defect that the fan blades 222 are installed at an excessively large angle, the angle of the airflow entering the fan blades is too large and the airflow stripping phenomenon occurs, resulting in a large fan load and power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com