Automatic optimization control method of boiler air-supply volume

A control method and automatic optimization technology, applied in the combustion method, adjusting the air supply, controlling the combustion, etc., can solve the problems of high cost and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

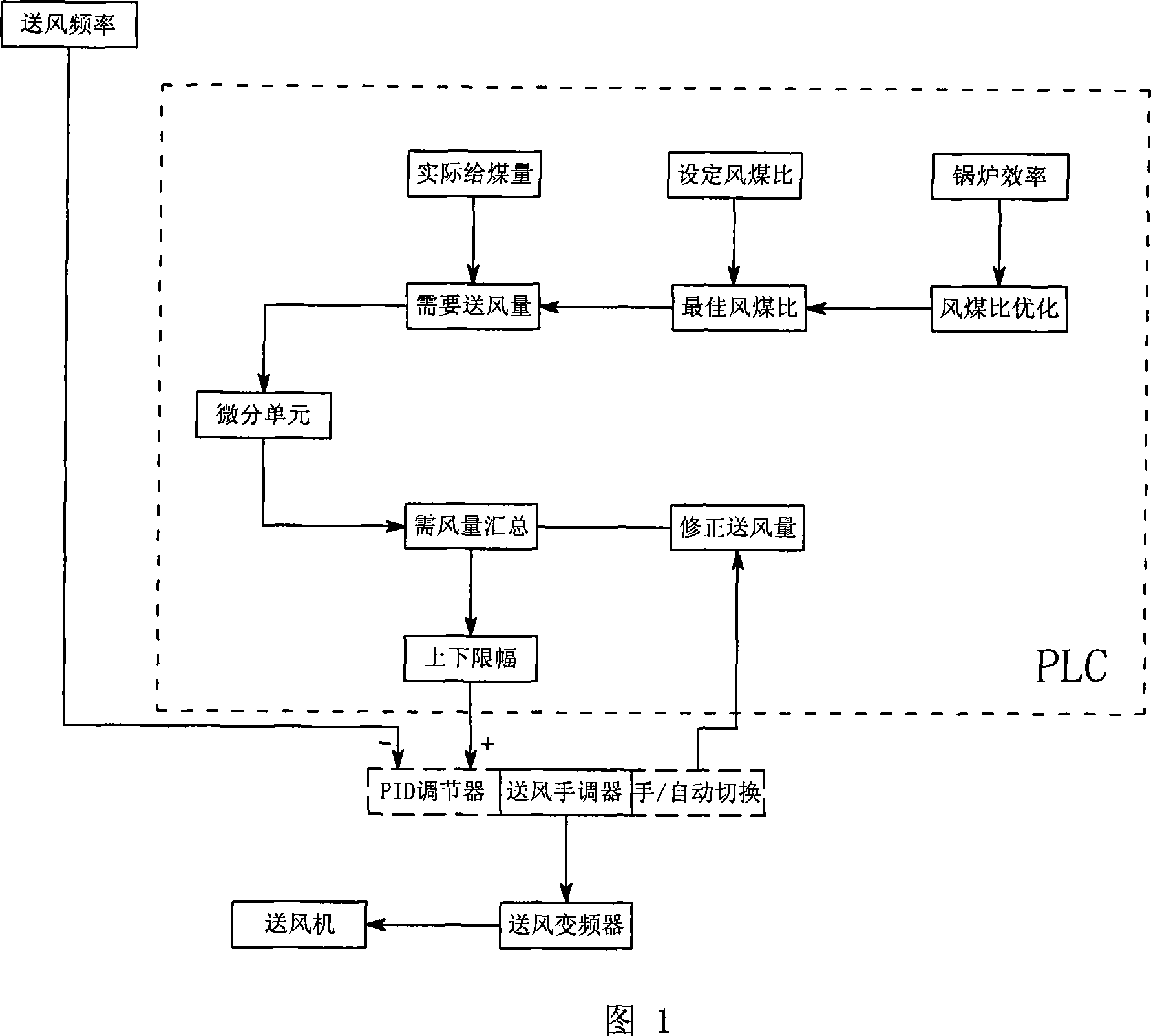

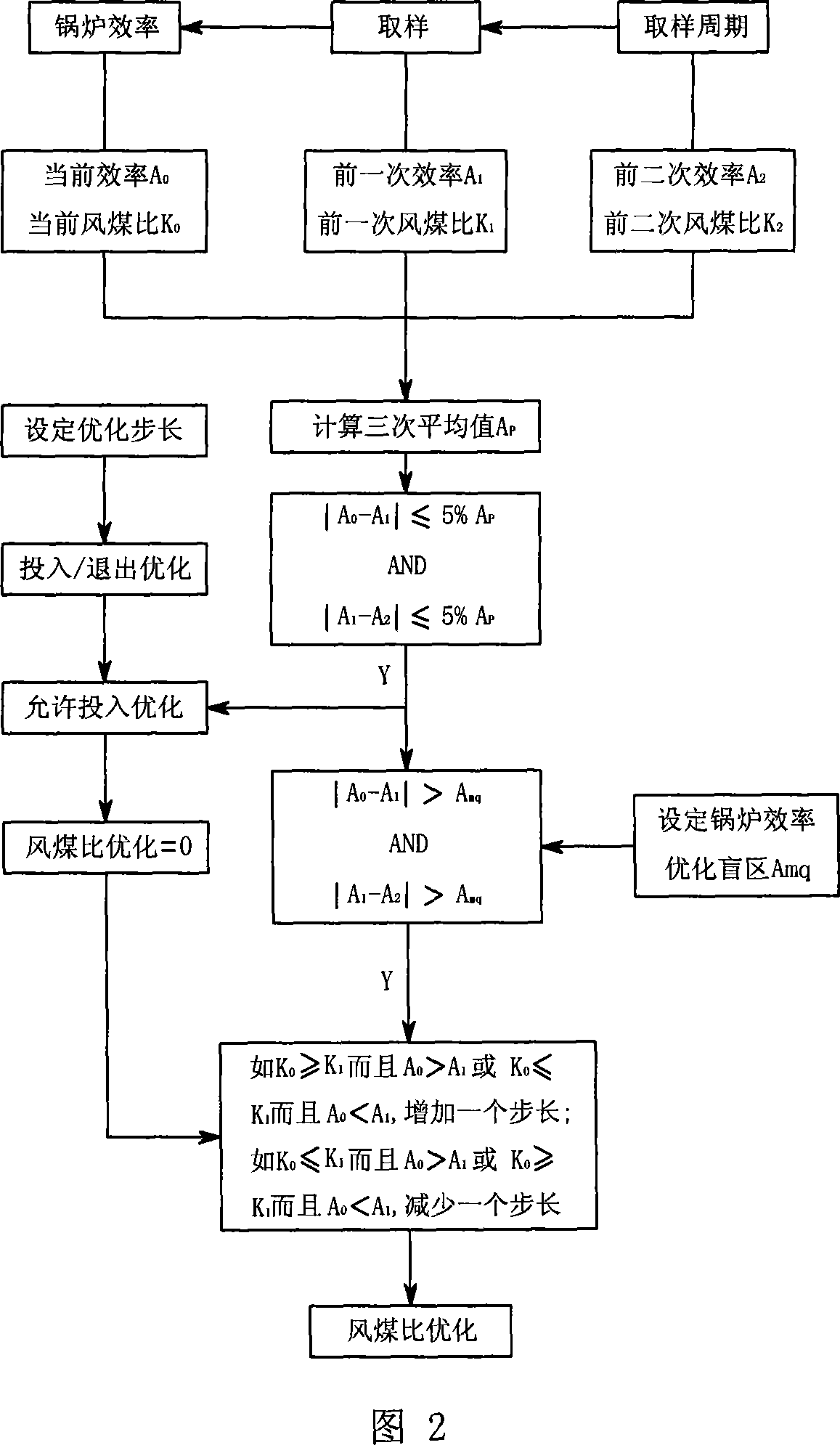

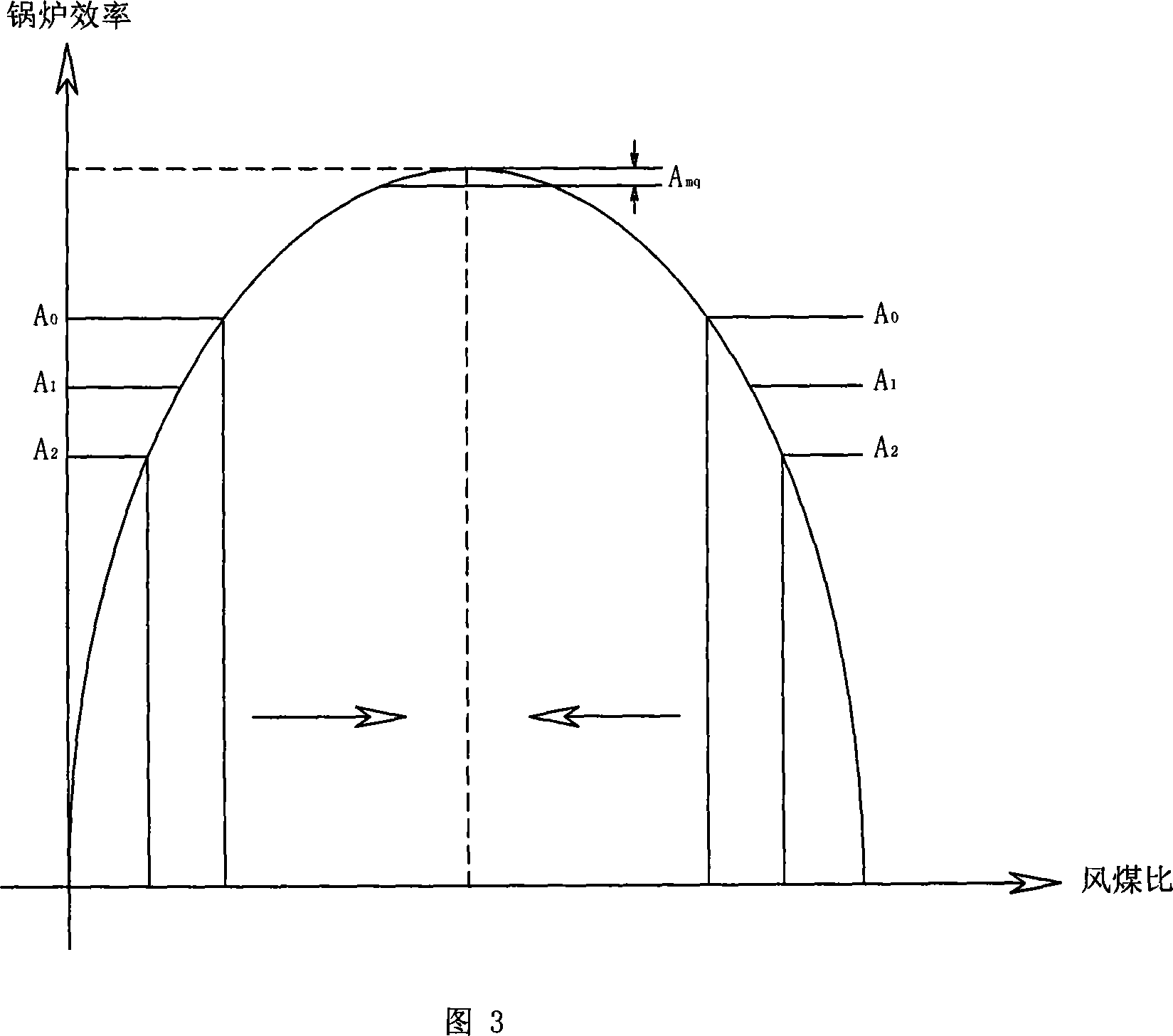

Method used

Image

Examples

Embodiment

[0038] In four 35T / h chain furnaces of Thermal Power Division of Shunde Jinfang Group, Foshan City, Guangdong Province, adopt the method of the present invention to carry out the automatic control of air supply volume, set air-to-coal ratio=0.6, sampling period=30 seconds, Optimization step length = 0.5; in use, the thermal efficiency of the boiler can be obtained through the measurement of the amount of coal and the flow of superheated steam. Compared with the manual control of the boiler worker with more than 10 years of operating experience, the thermal efficiency has increased by at least 2%, and the economy The benefits are very obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com