Device for heating using residual heat of sulfuric acid production

A technology for low-temperature waste heat and sulfuric acid production, which is applied in hot water central heating systems, household heating, applications, etc., to achieve the effects of easy transformation, energy and cost saving, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

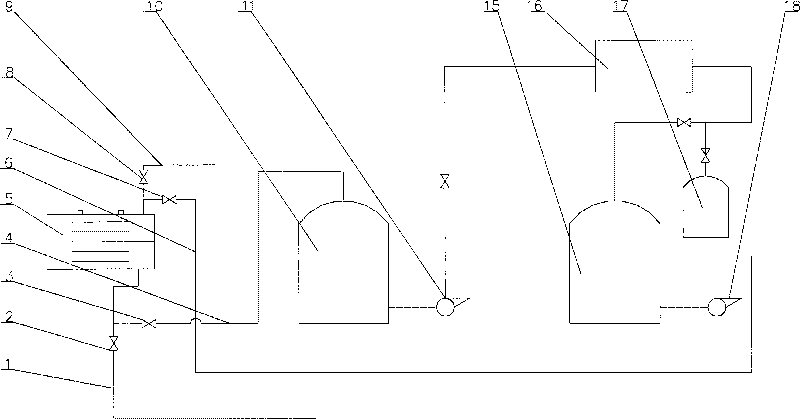

Embodiment 1

[0020] Such as figure 1 As shown: the acid cooler is an anode-protected shell-and-tube acid cooler 5, and the tube side of the anode-protected shell-and-tube acid cooler 5 is connected to the circulating water inlet pipe 9 and the circulating water outlet pipe 1, and the anode-protected shell-and-tube acid cooler The shell side of the device 5 is connected with the acid inlet pipe and the acid outlet pipe. The circulating water inlet pipe 9 and the circulating water outlet pipe 1 are respectively provided with a valve 8 and a valve 2. The tube-side outlet of the protective shell-and-tube acid cooler 5 is connected, the outlet of the warm water tower 15 is connected to the tube-side inlet of the anode protection shell-and-tube acid cooler 5 through the heating water warm water pipe 6, and the heating water and hot water pipe 4 is provided with a valve 3 , the heating water warm water pipe 6 is provided with a valve 7, a hot water pump 11 is arranged on the hot water pipe betwe...

Embodiment 2

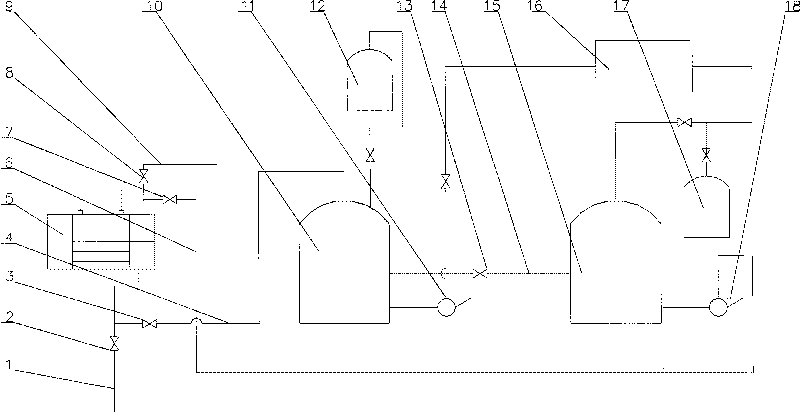

[0025] Such as figure 2 As shown: the heating circulating water warming device is provided on the hot water tower 10, the heating circulating water warming device is a steam boiler 12, a connecting pipe 14 is provided between the hot water tower 10 and the warm water tower 15, and the connecting pipe 14 is provided with Valve 13, other same figure 1 .

[0026] In the seasons of spring, summer and autumn when heating is not needed, this embodiment is the same as embodiment 1.

[0027] In winter when heating is required, this embodiment is the same as Embodiment 1 during normal heating.

[0028] In the winter when heating is required, when the sulfuric acid production equipment temporarily stops, in order not to affect the heating, the warm water pump 18 can be shut down, and the valve 13 can be opened at the same time, so that the hot water tower 10 is connected with the warm water tower 15, and the steam boiler 12 is sent to the hot water tower. A small amount of high-tem...

Embodiment 3

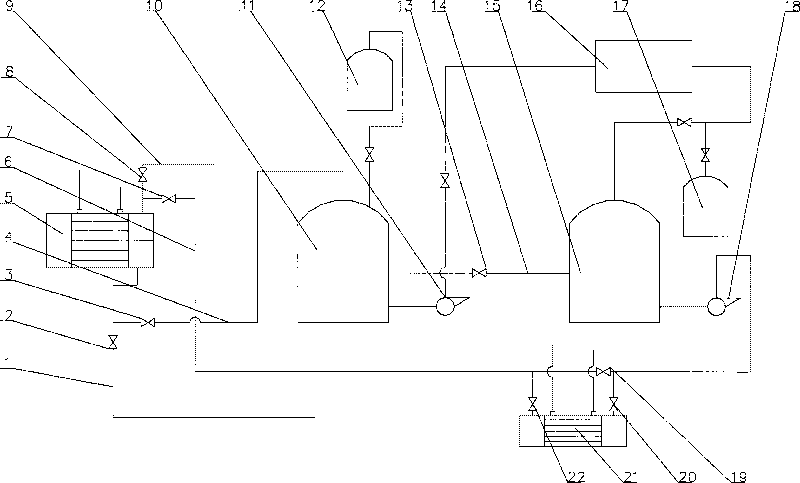

[0031] Such as image 3 As shown: the heating water temperature pipe 6 is provided with a heating circulating water cooling device, the heating circulating water cooling device is a shell-and-tube heat exchanger 21, a valve 19 is added on the heating water temperature pipe 6, and the tube of the shell-and-tube heat exchanger 21 The process is connected to the heating water temperature water pipe 6 through the water inlet pipe and the water outlet pipe. The water inlet pipe and the water outlet pipe of the tube side of the shell and tube heat exchanger 21 are respectively provided with a valve 20 and a valve 22. Others are the same figure 2 .

[0032] In the seasons of spring, summer and autumn that do not require heating, this embodiment is the same as embodiment 1.

[0033] In the winter when heating is required, during normal heating or when the sulfuric acid production equipment temporarily stops or when the heat provided by the low-temperature waste heat to the heating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com