Thermometer calibration by immersion in non-electrically conductive liquid

A non-conductive, electronic temperature technology used in the field of calibration systems to solve problems such as increased calibration time, package leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

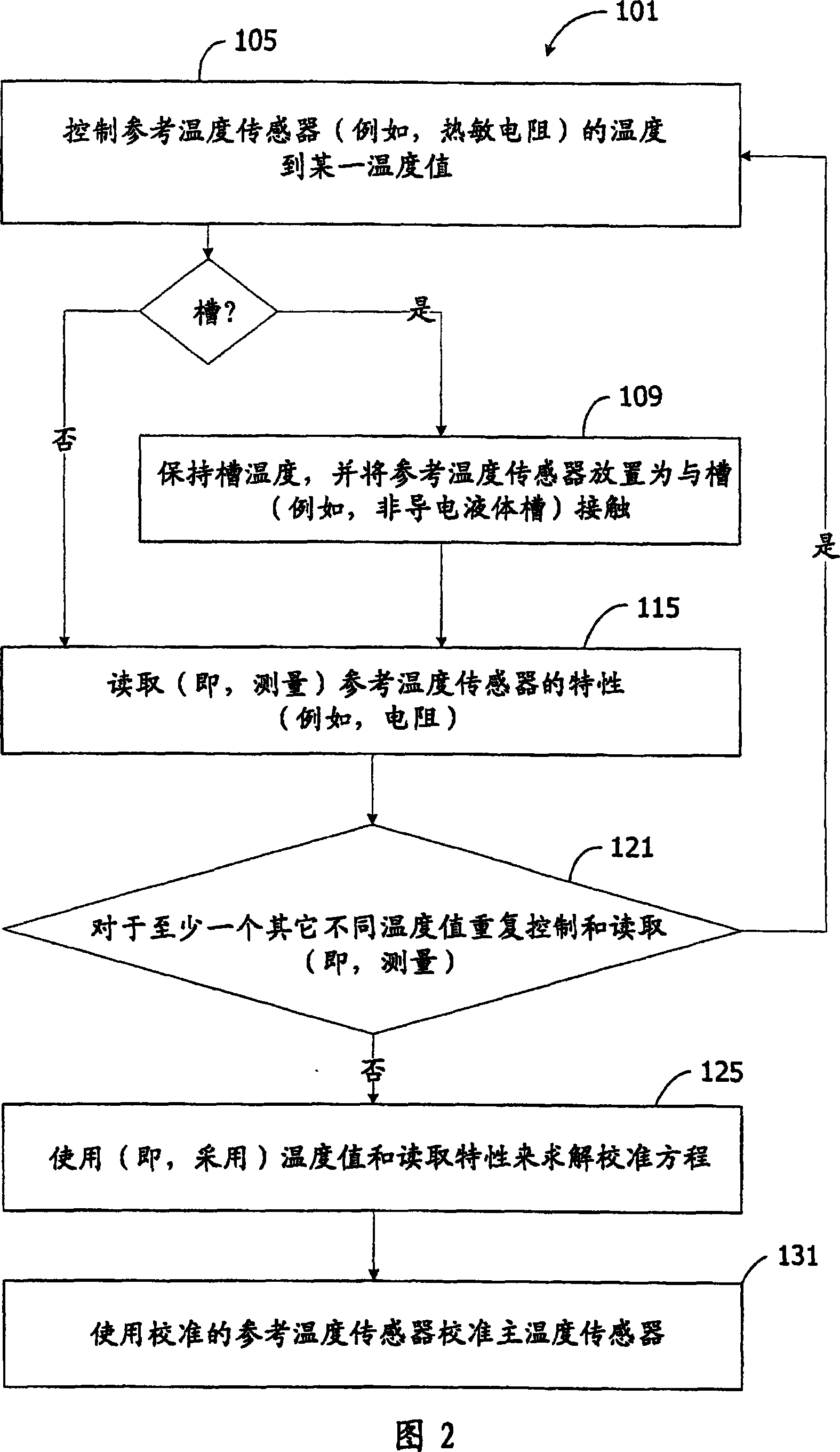

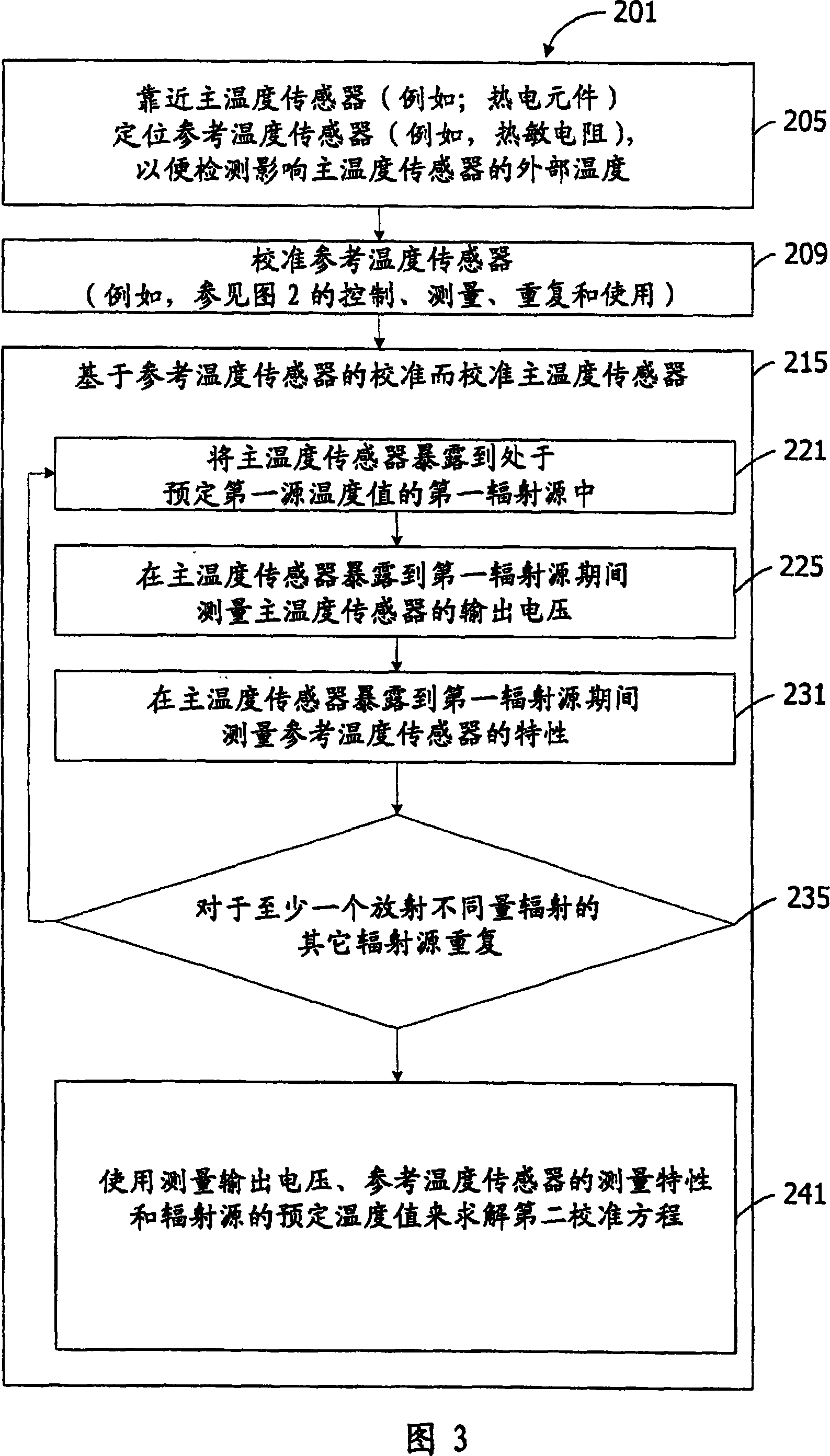

Method used

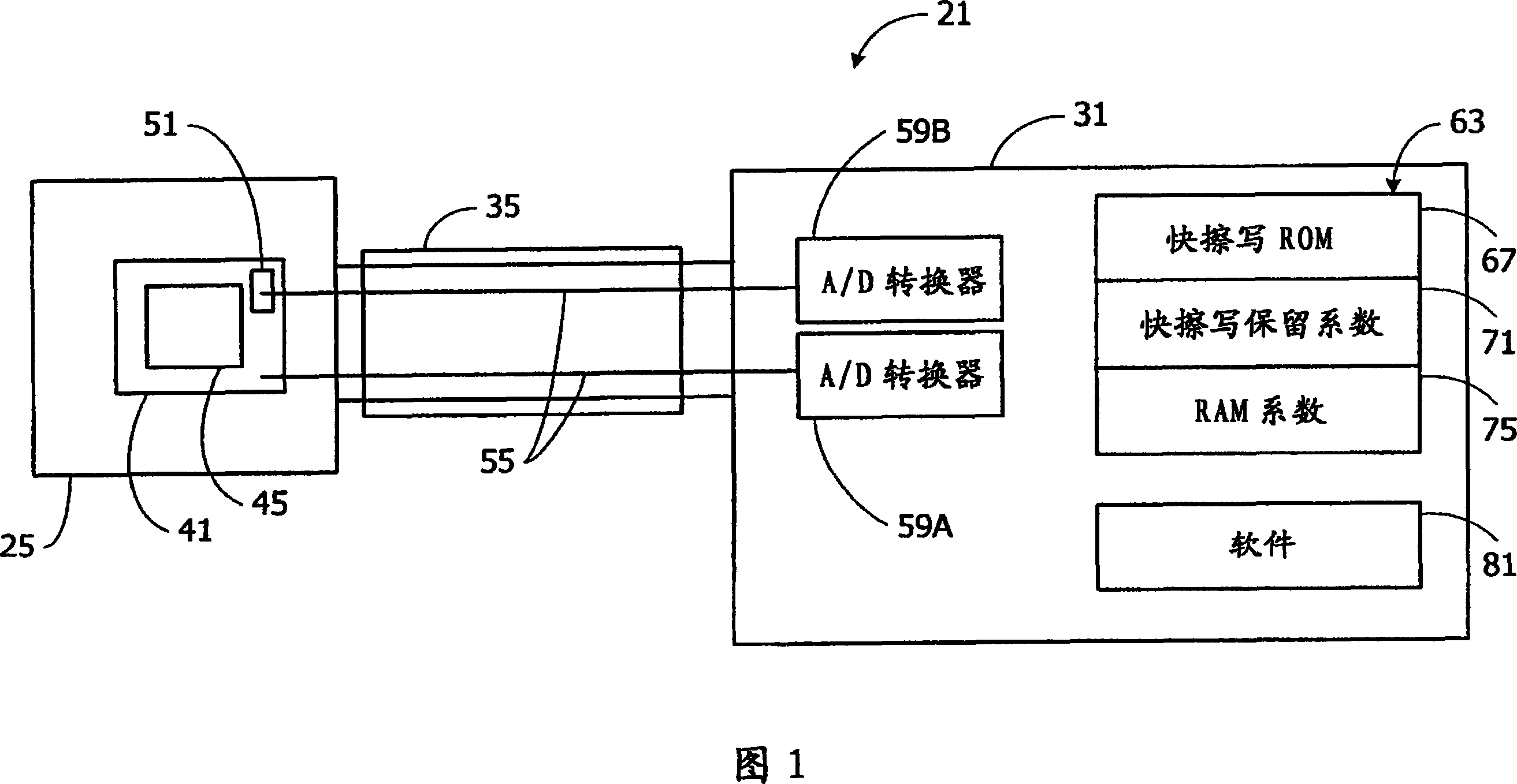

Image

Examples

example

[0053] The following example demonstrates the application of the first and second calibration equations to a Dexter ST60 polysilicon resistor. This example uses the following equation, where the temperature is converted to absolute temperature:

[0054] T s = a + b R + c R 2

[0055] Specifically, the temperature of the reference temperature sensor may be controlled to a first temperature value of 10°C (50°F), a second temperature value of 25°C (77°F), and a third temperature value of 40°C (104°F). With these three temperatures, these three equations and three unknowns can be solved for a, b and c as follows:

[0056] a = T 10 · R 10 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com