Visual inspection device and method

A visual inspection device and technology for visual inspection, which are applied to measurement devices, optical devices, instruments, etc., can solve the problems of large size, increase in the number of parts, and decrease in reliability, and achieve the effect of a simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

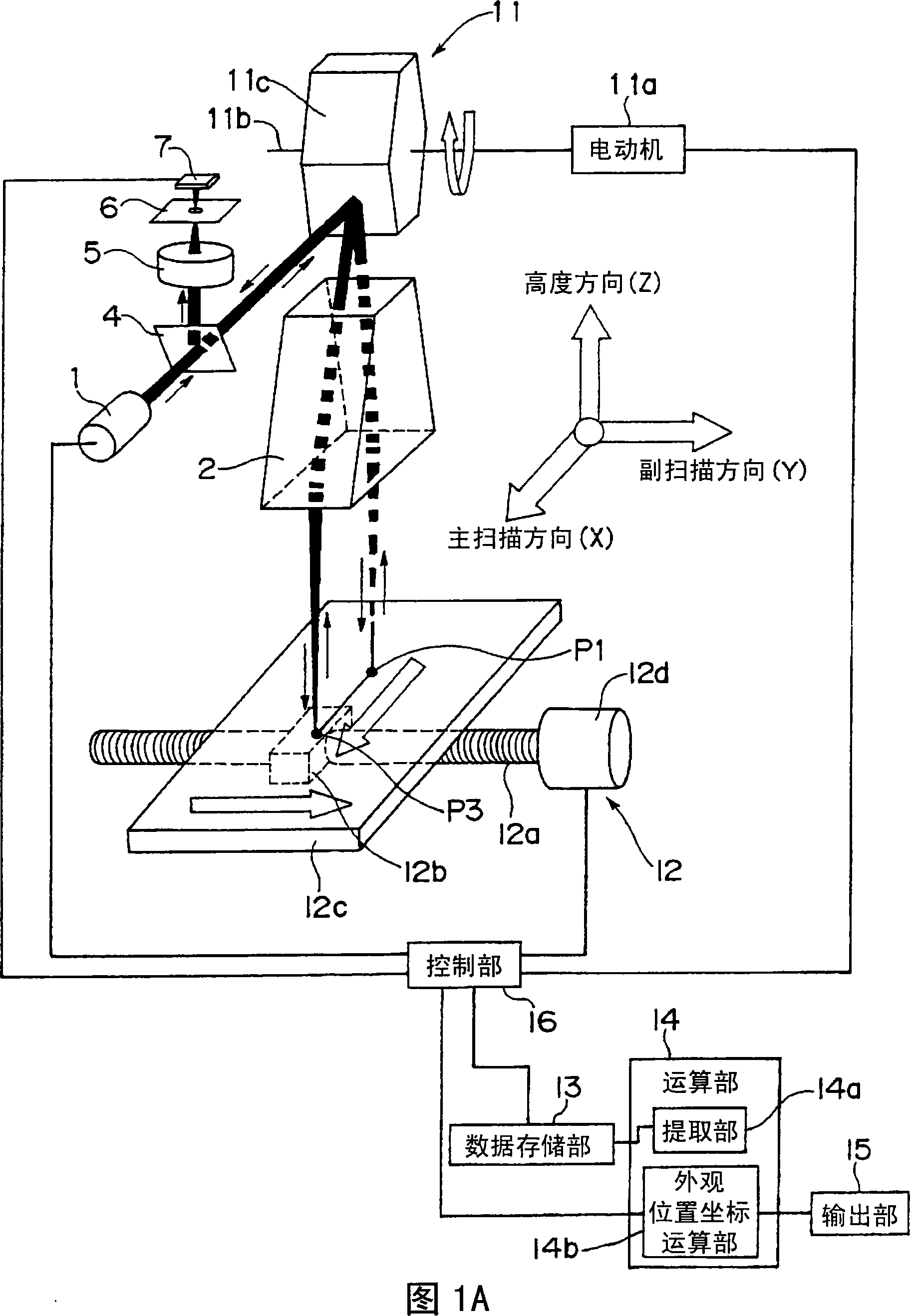

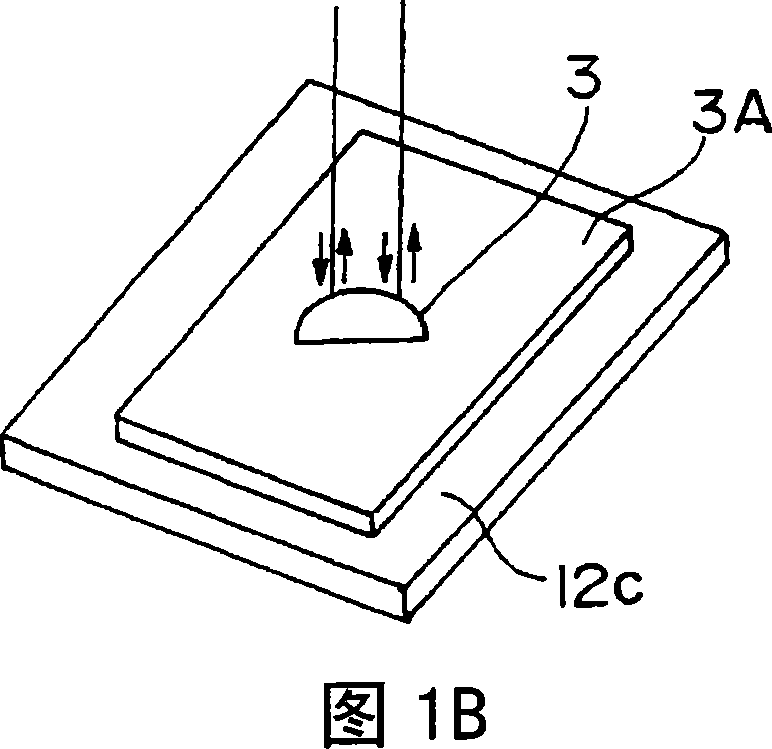

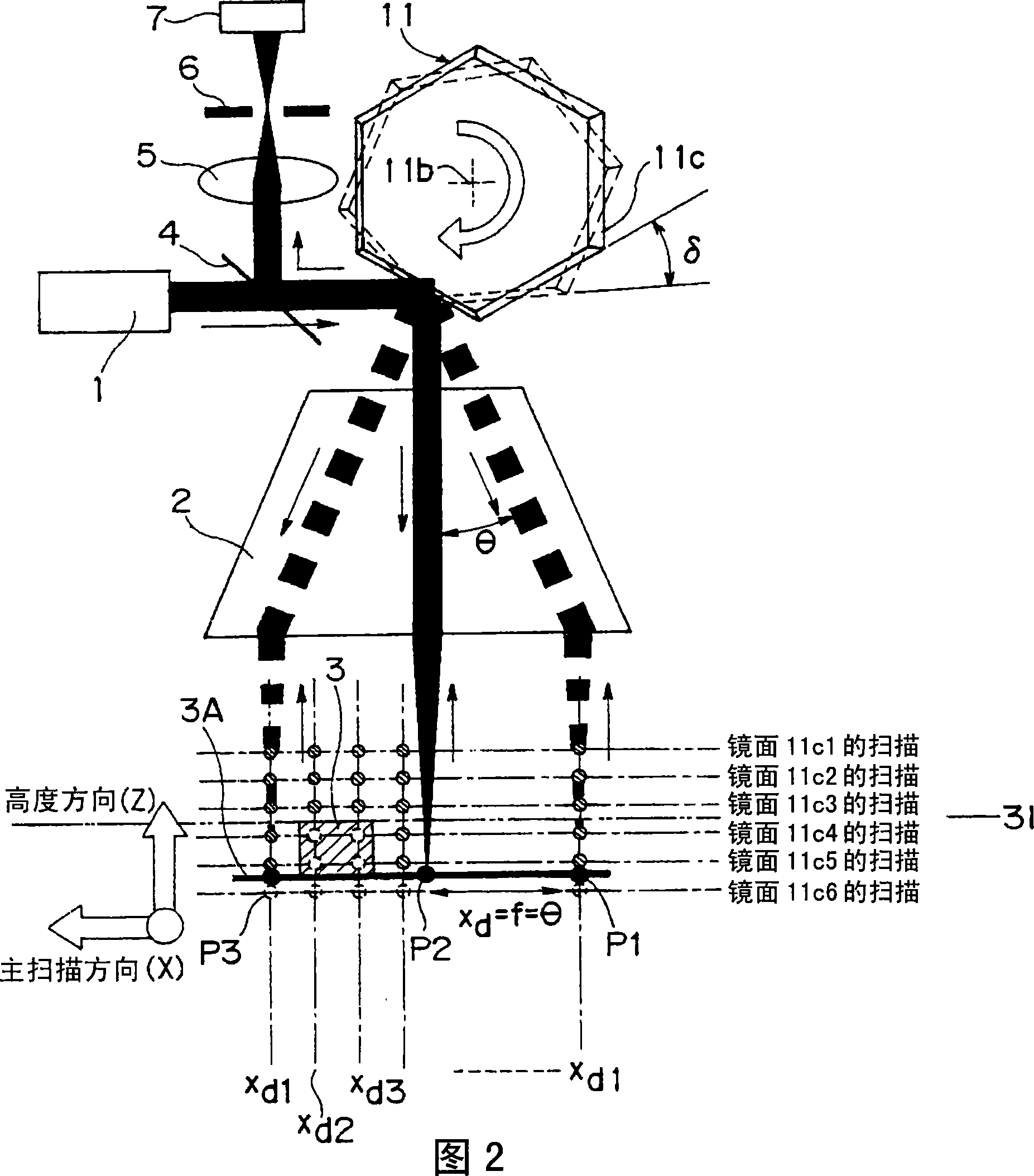

[0064] 1A is a schematic perspective view showing the configuration related to the optical system and the mechanical system of the visual inspection device in the first embodiment of the present invention, and FIG. 1B is a partially enlarged perspective view of FIG. 1A showing the inspection object 3 . In addition, FIG. 2 is a schematic diagram of the same optical system viewed from the sub-scanning direction.

[0065] First, the basic structure of the visual inspection device in the first embodiment of the present invention will be described using FIGS. 1A and 1B .

[0066] The appearance inspection apparatus in the first embodiment of the present invention includes: a light source 1, a rotating polygon mirror 11, a motor 11a, a scanning condenser lens 2 constituting an example of an optical system for forming a focal point position, a light splitting mirror 4, a reflected light Condenser lens 5, shielding plate 6, photodetector 7, table transport device 12 as an example of i...

no. 2 approach 》

[0143] 9A is a schematic diagram of the configuration of the optical system of the visual inspection apparatus and method in the second embodiment of the present invention viewed from the sub-scanning direction Y. FIG. 9B is a schematic diagram of the configuration of the optical system of the visual inspection device in the second embodiment of the present invention viewed from the main scanning direction X. FIG.

[0144] The appearance inspection device and method according to the second embodiment of the present invention, as shown in FIGS. 9A and 9B , includes a method that does not tilt the optical axis of the scanning condenser lens 2 from a plane perpendicular to the rotation axis 11b of the rotating polygon mirror 11. The scanning condenser lens 2A is arranged parallel to the height direction Z at an angle β, and an example of an optical system for forming a focal point position is provided between the scanning condenser lens 2A and the object 3 to be inspected. 1. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com