Method for founding main regulation valve body of steam turbine

A steam turbine and regulating valve technology, applied in casting equipment, casting molding equipment, casting molds, etc., can solve the problems of difficult cleaning of inner cavity core sand, poor feeding conditions, and difficult mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

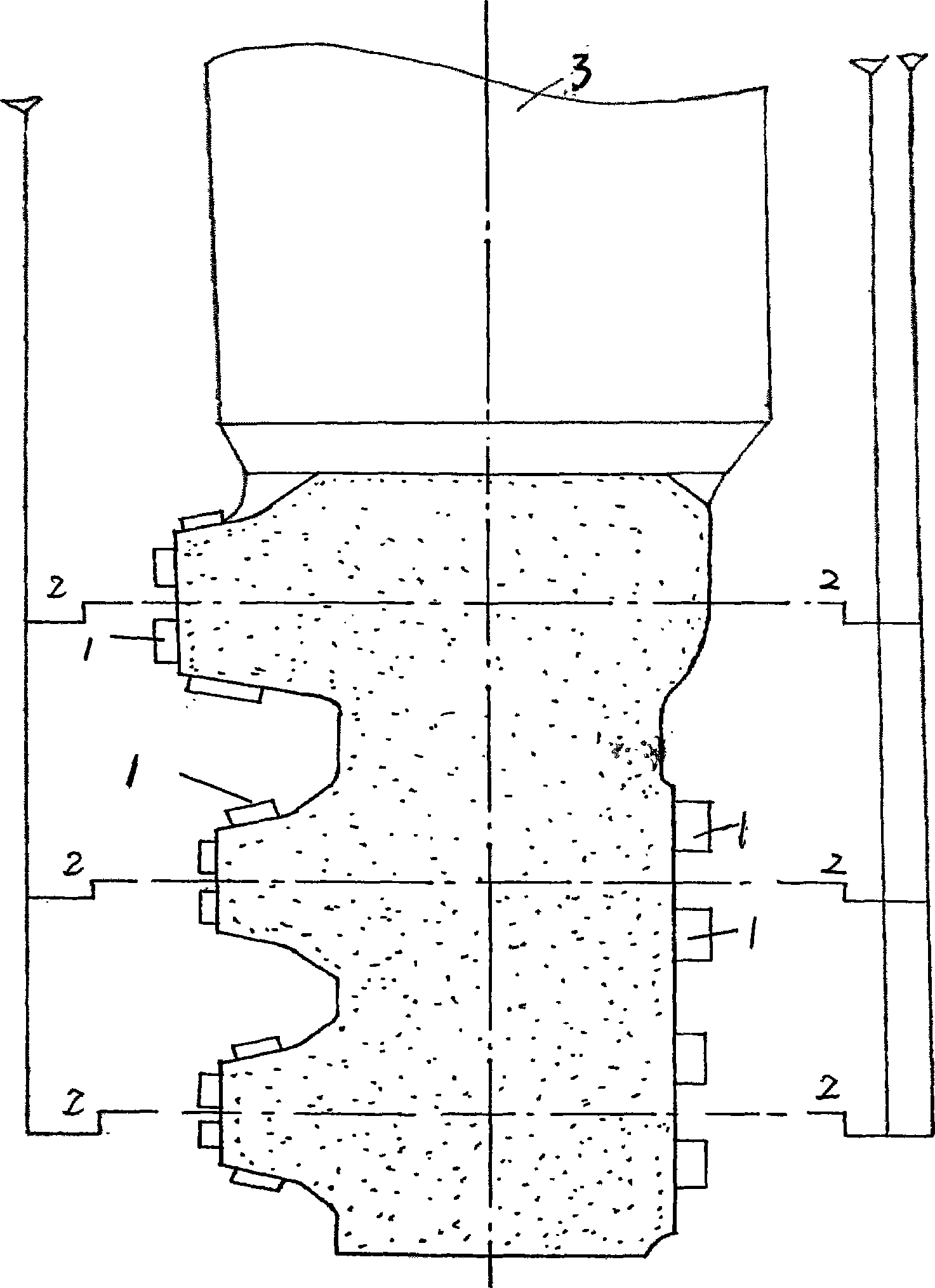

[0025] The casting method of the main steam regulating valve body of the steam turbine adopts the process of horizontal casting and vertical casting and two-stage heat treatment:

[0026] 1. Flat pouring:

[0027] a) Flat casting: place the mold flat, cover the surface of the mold with magnesia carbon sand of 50-100mm as the surface layer, and fill the rest of the back sand; place a spacer of 10-30mm at an interval of 50-100mm on the flange part (end face and circumference) Sand cold iron sand barrier layer 1; blow carbon dioxide gas to harden the mold, take out the mold, put the mold in a drying kiln at 150-300°C for 12-16 hours, and paint the zircon powder water-based paint after leaving the kiln ;

[0028] b) Vertical pouring: After assembling and tightening several parts of the mold, stand it up for pouring. There are several layers (generally three to four layers or depending on the specific situation) on both sides from bottom to top. Gate 2 , a riser 3 made of insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com