Sheet feeding device and image forming apparatus

A technology for paper feeding devices and imaging devices, applied in printing devices, transportation and packaging, printing, etc., can solve the problems of troublesome insertion of mandrel parts, increase of manufacturing costs, and increase in the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

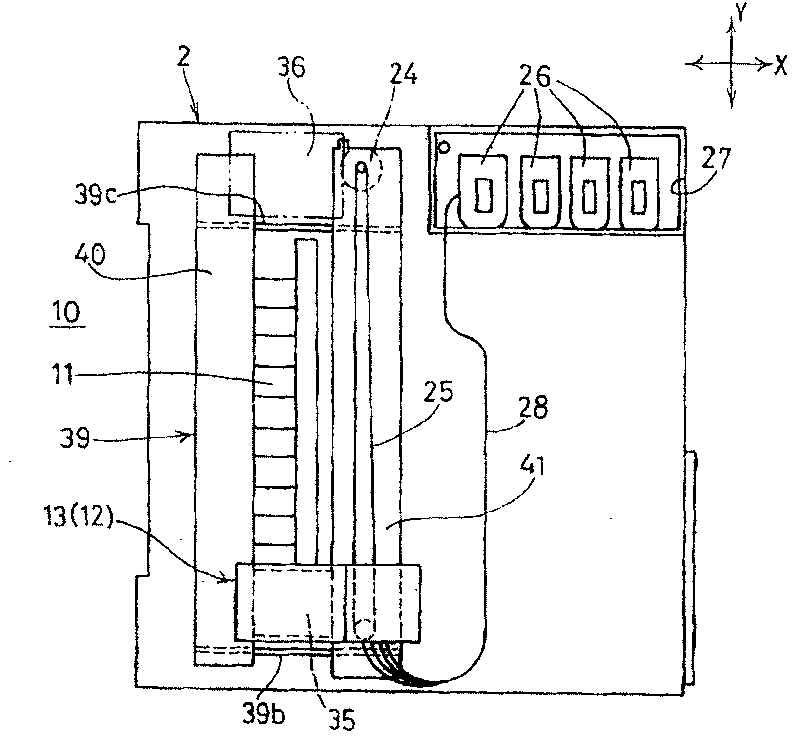

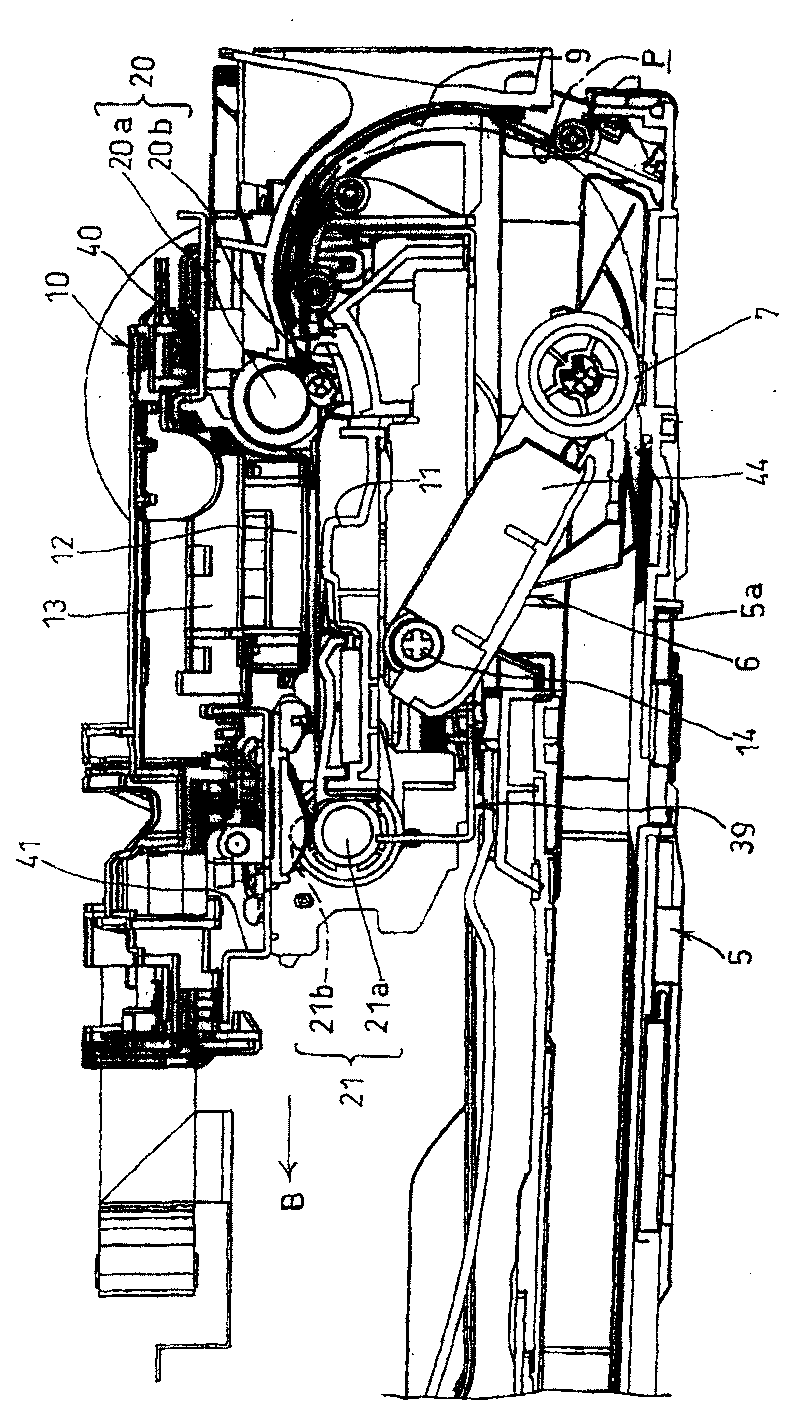

[0031] Examples of the present invention will be described below with reference to these drawings.

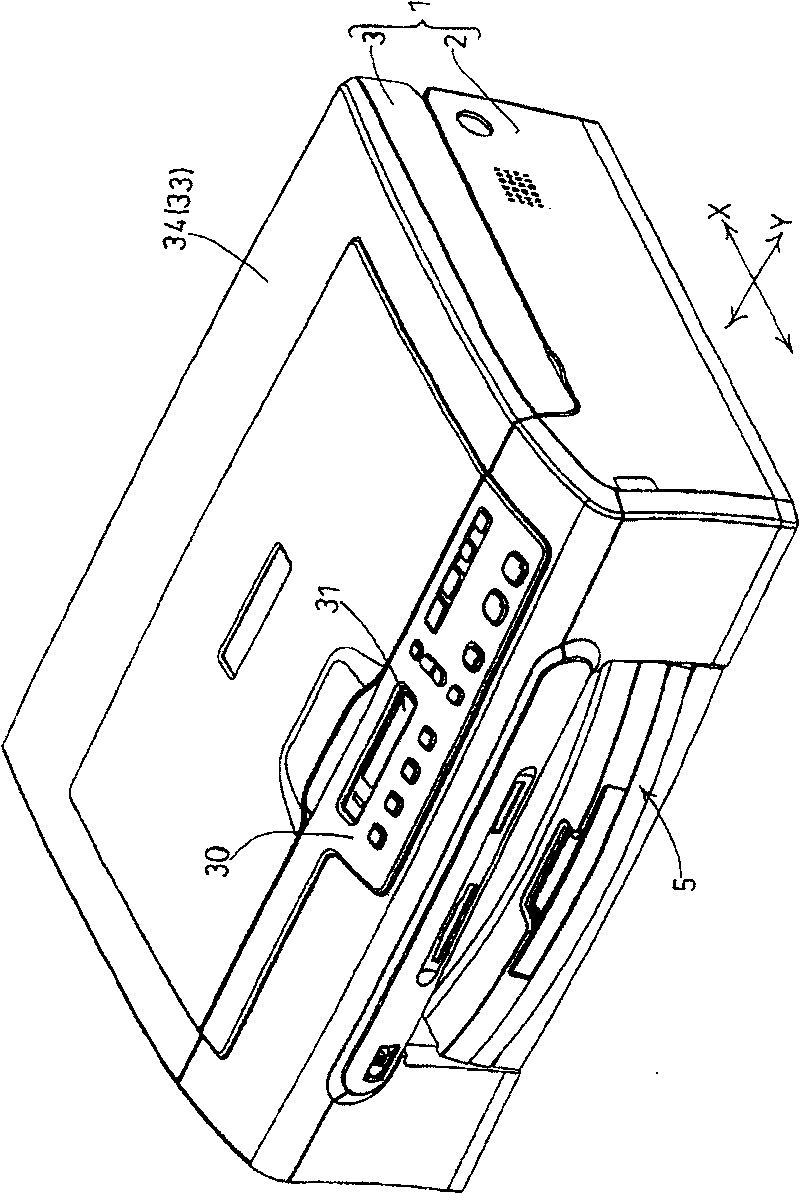

[0032] exist figure 1 An image forming apparatus 1 according to an example of the present invention is shown in . This image forming apparatus 1 has various functions, such as a facsimile function, a printing function, a copying function, and a scanning function, so as to function as a multifunction device (MFD). The image forming apparatus 1 includes: a substantially box-shaped main body casing 2 opened at its upper portion; and an upper casing 3 which is pivotally mounted on the main body casing 2 so as to rotate vertically around a rotation shaft (not shown). , the rotation axis is constituted by a hinge provided at the rear side along the rear surface of the main body casing 2 .

[0033] In the description here, the near side (the side facing the user) of the imaging apparatus 1 is determined as the front side. The left-right direction (main scanning direction or Y-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com