Compressor intercooling system

A cooling system and compressor technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of consuming scarce resources, increasing equipment costs, complex structure, etc., to reduce workload, simplify operation, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

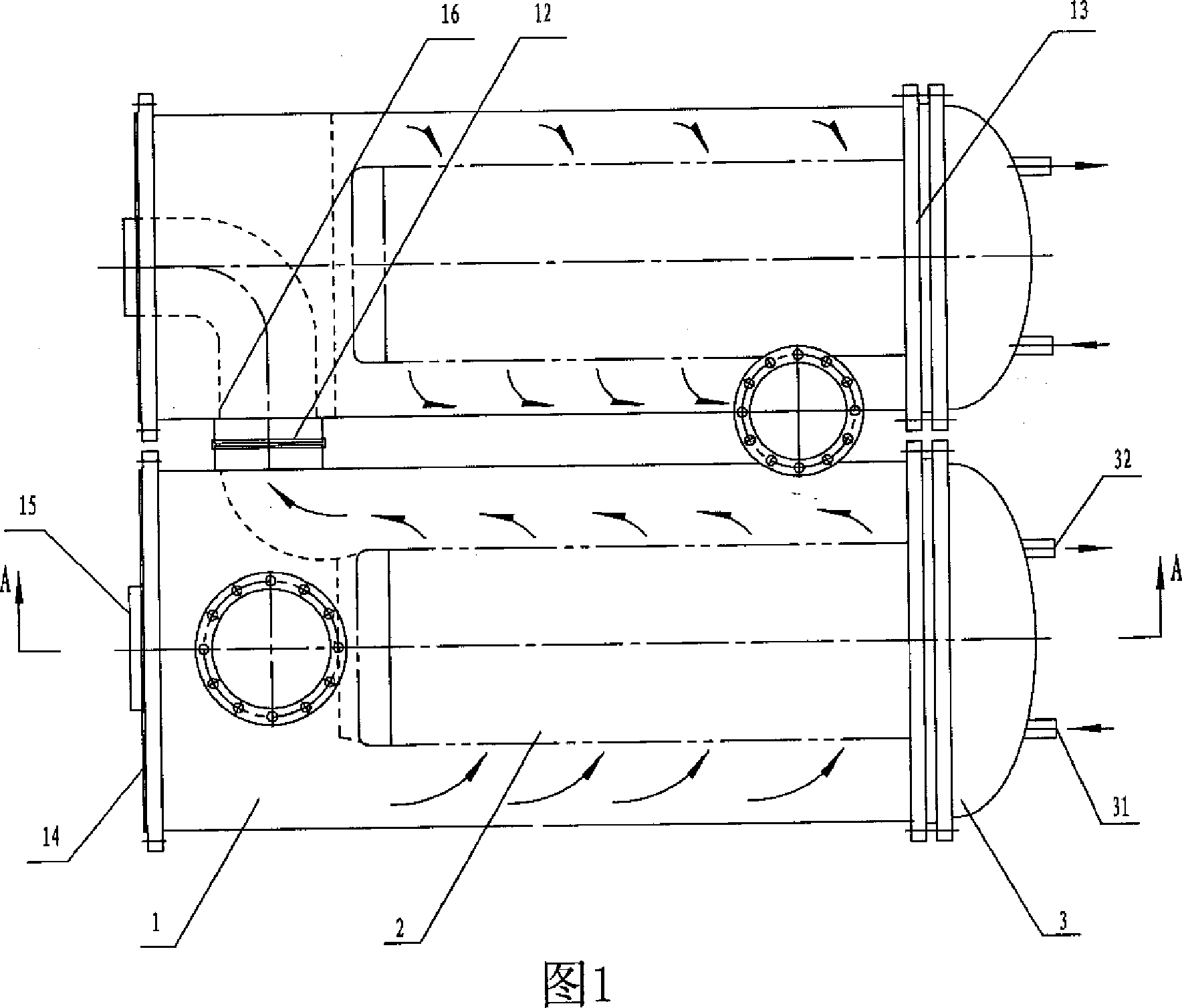

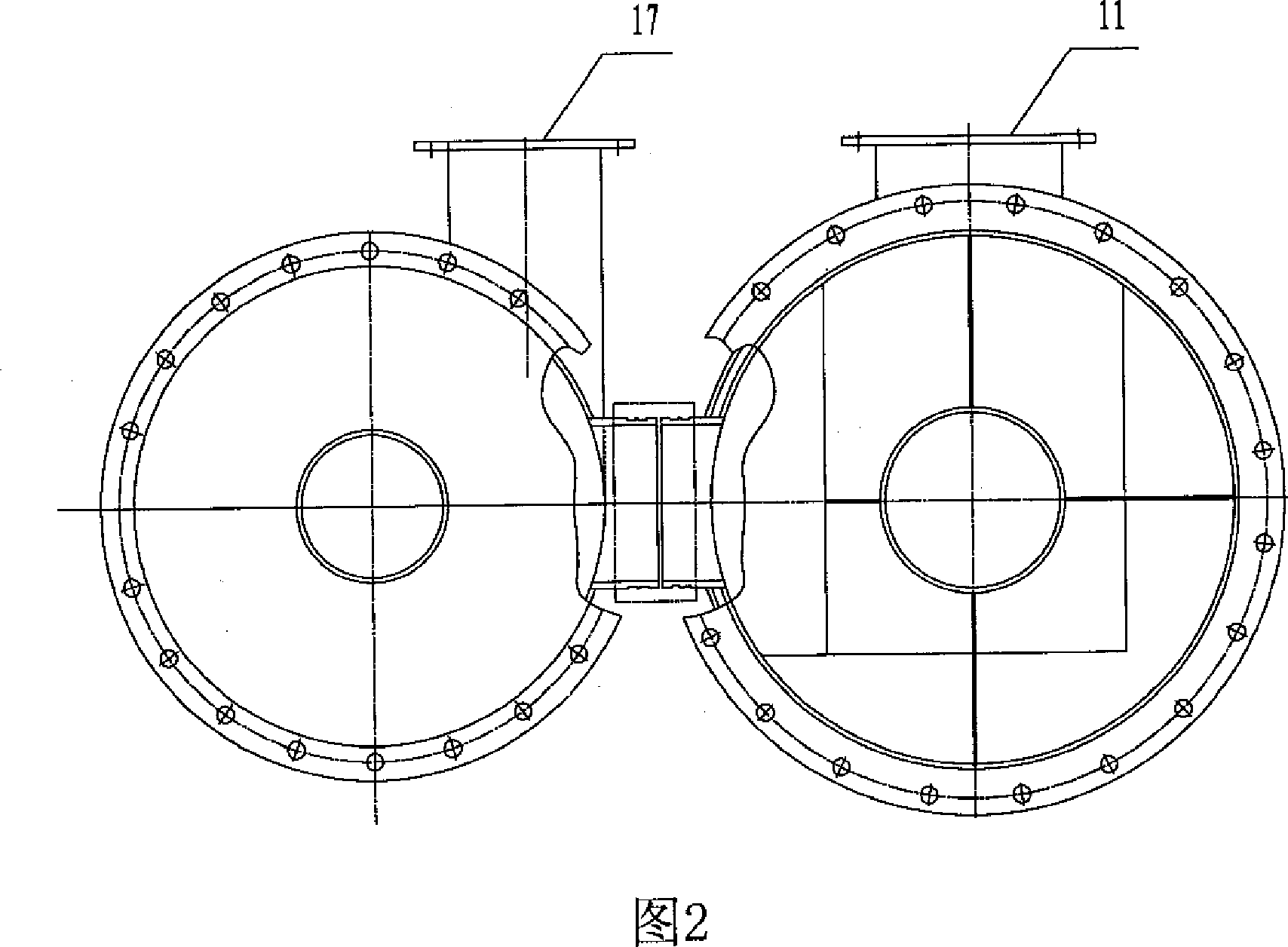

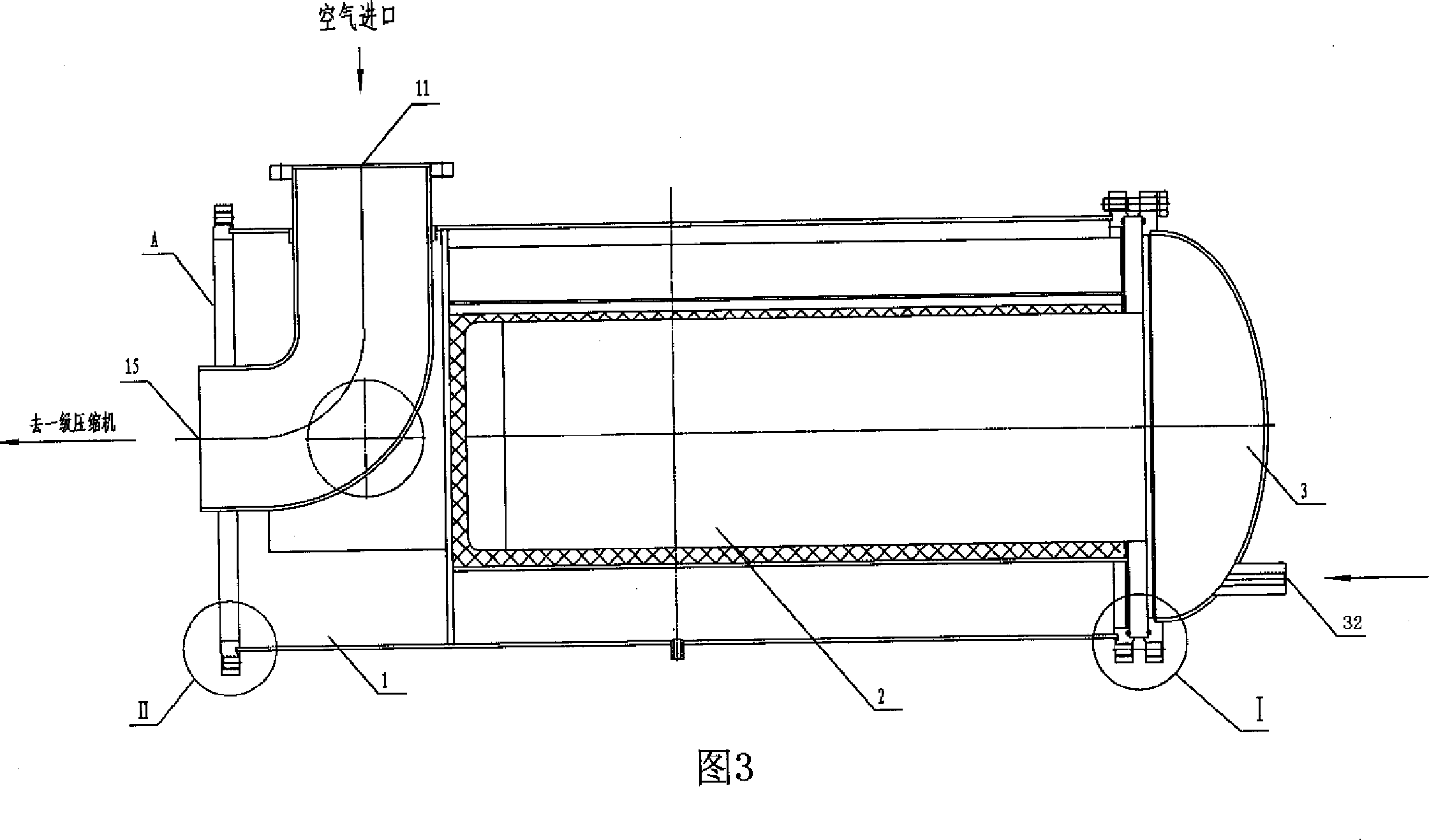

[0013] It can be seen from Figures 1 to 7 that the present invention includes a shell 1, a core body 2, a water diversion cover plate 3, and its feature is that the shell 1, a core body 2, and a water diversion cover plate 3 form an intercooler unit, and At least two intercooler units make up the compressor intercooling system; the first-stage intercooler is provided with an air inlet 11 for introducing ambient air into the first-stage compressor inlet, and the first-stage intercooler is also provided with a row The air port 12 is used to discharge the cooled air to the air inlet of the secondary compressor; the secondary intercooler is also provided with an air inlet 16 and an exhaust port 17, and the exhaust of the primary and secondary intercoolers The ports are connected with the next-stage air inlets to form a system in series; the core 2 adopts circulating water cooling mode, the core 2 tube passes circulating cooling water, the heat transfer fins pass through the tube, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com