Frame comprising a vibration-damping device, which is intended for the outside rear-view mirror assembly of a motor vehicle

A technology of rearview mirror assembly and vibration damping device, which is applied to vehicle components, transportation and packaging, optical observation devices, etc., can solve the problems of inflexibility, instability, and insufficient damping of the moving plate, and achieve increased reliability and failure The effect of risk elimination and metal noise prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

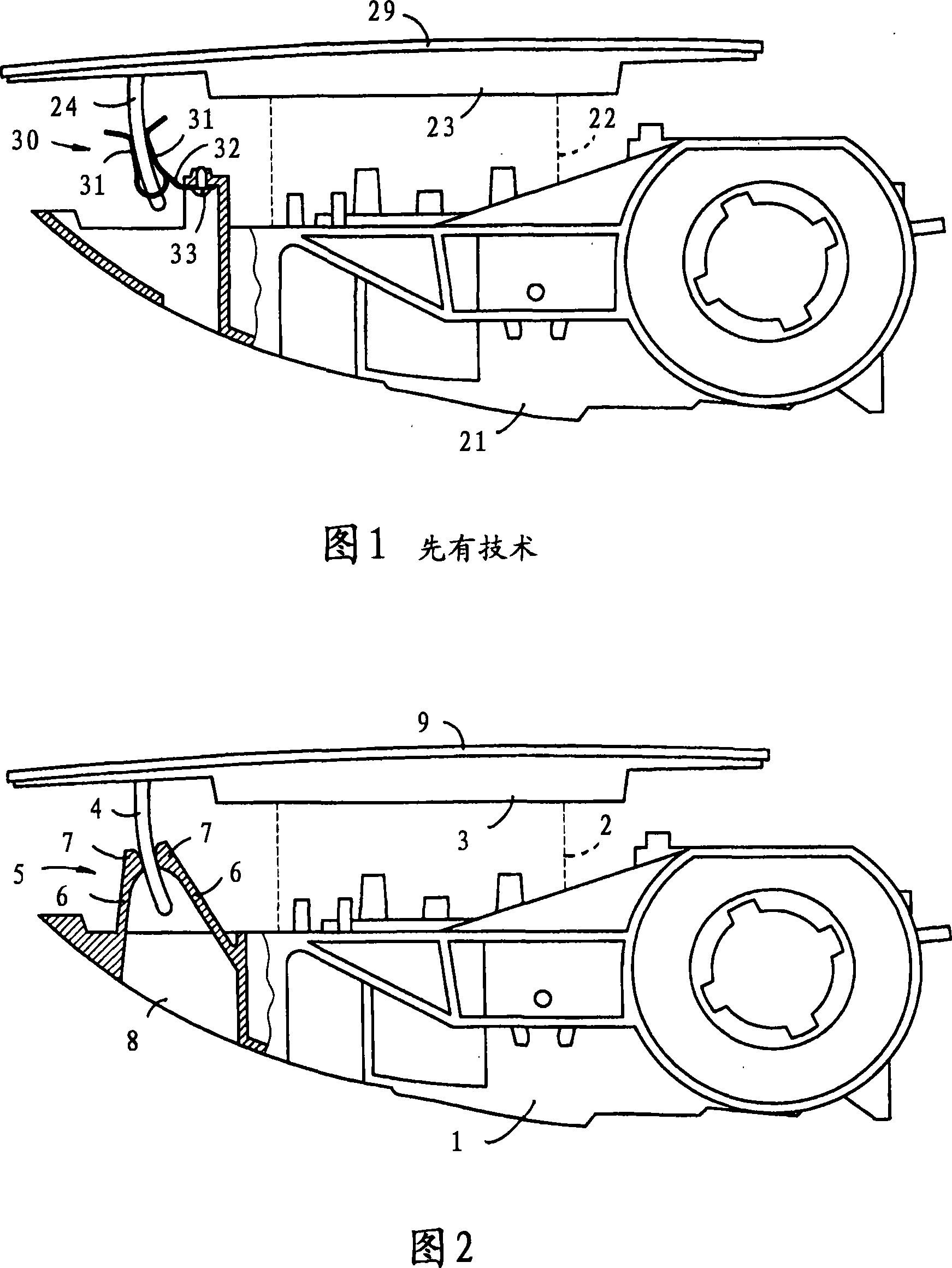

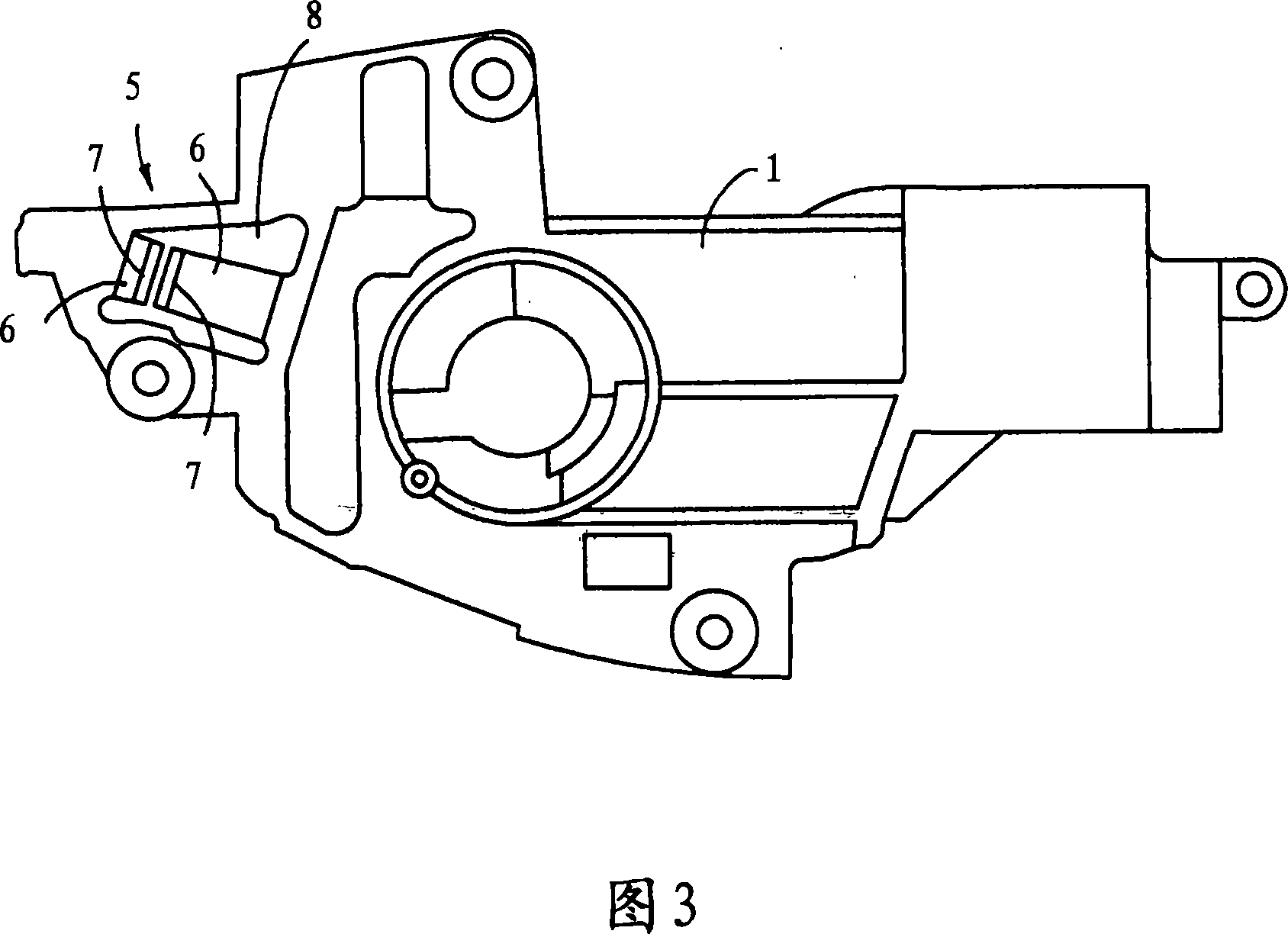

[0014] Reference is made to Figure 1, which shows a frame 21 including vibration damping means for an exterior rearview mirror assembly of a motor vehicle according to the closest state of the art. The aforementioned frame 21 is adapted to support a mobile plate 23 to which at least one mirror 29 is fixed. The above-mentioned mobile plates 23 are assembled by means of joints of the joint type that allow joint rotation of the mobile plates 23 on two coordinate axes. A box is generally mounted on the frame 21, the box housing the adjustment mechanism including movement transmission means connected to the moving plate 23 for changing its position. The box houses said adjustment mechanism, said knuckle-type joint being conventional and schematically shown as a whole by dashed line 22 in FIG. 1 .

[0015] In order to attenuate possible vibrations transmitted from the frame 21 to the mobile plate 23 , the mobile plate 23 comprises tabs 24 protruding outwards from the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com