PCB plate double-face drilling and positioning method

A technology of PCB board and positioning method, which is applied in positioning devices, drilling/drilling equipment, components of boring machines/drilling machines, etc., can solve the problems of misalignment of zero points, easy breakage of drill bits, affecting product quality, etc., and achieve positioning accuracy. High, reduce deviation, improve the effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

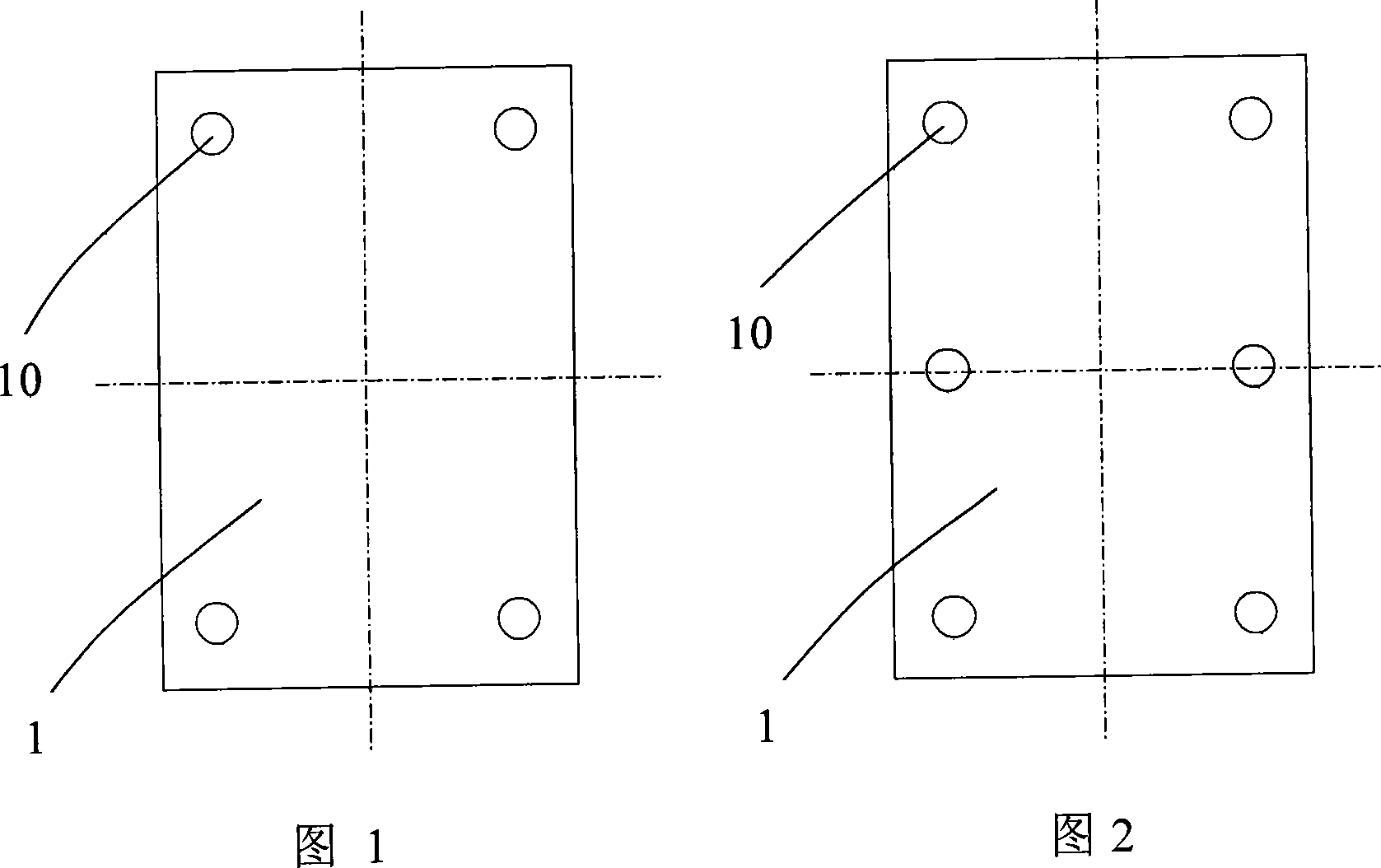

[0009] As shown in Fig. 1, the present invention provides a kind of PCB board double-sided drilling positioning method, it is provided with at least 4 positioning holes 10 on the PCB board 1, and one-to-one correspondence between the drilling jig and the positioning holes Positioning pins are provided, and when holes are drilled from the front and back sides of the PCB board, the positioning pins and the positioning holes are matched one by one to position the PCB board. The positioning holes are distributed symmetrically. According to the size of the PCB board, the number of the positioning holes is generally 4-16, preferably 4-6. In the embodiment shown in FIG. 1 , four positioning holes are arranged symmetrically on the circuit board; while in another embodiment shown in FIG. 2 , six positioning holes are arranged symmetrically on the circuit board.

[0010] The present invention increases the number of positioning holes through the cooperation of positioning holes and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com