Manual tool with vibration reduction device

A technology of hand-held machine tool and connecting device, which is applied in the direction of manufacturing tools, striking tools, portable drilling rigs, etc., can solve the problems of large assembly cost and high manufacturing cost, and achieve the effect of preventing locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

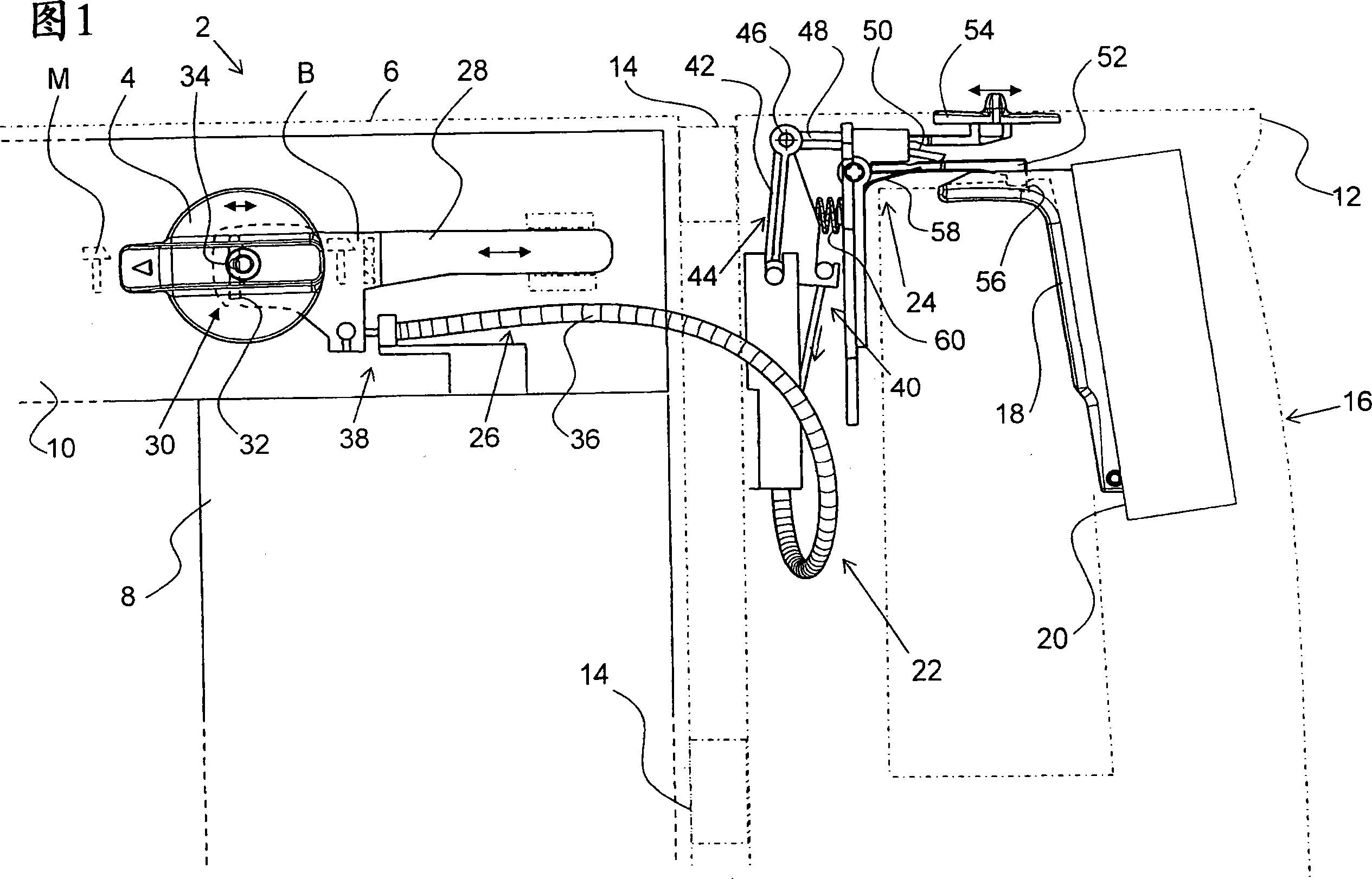

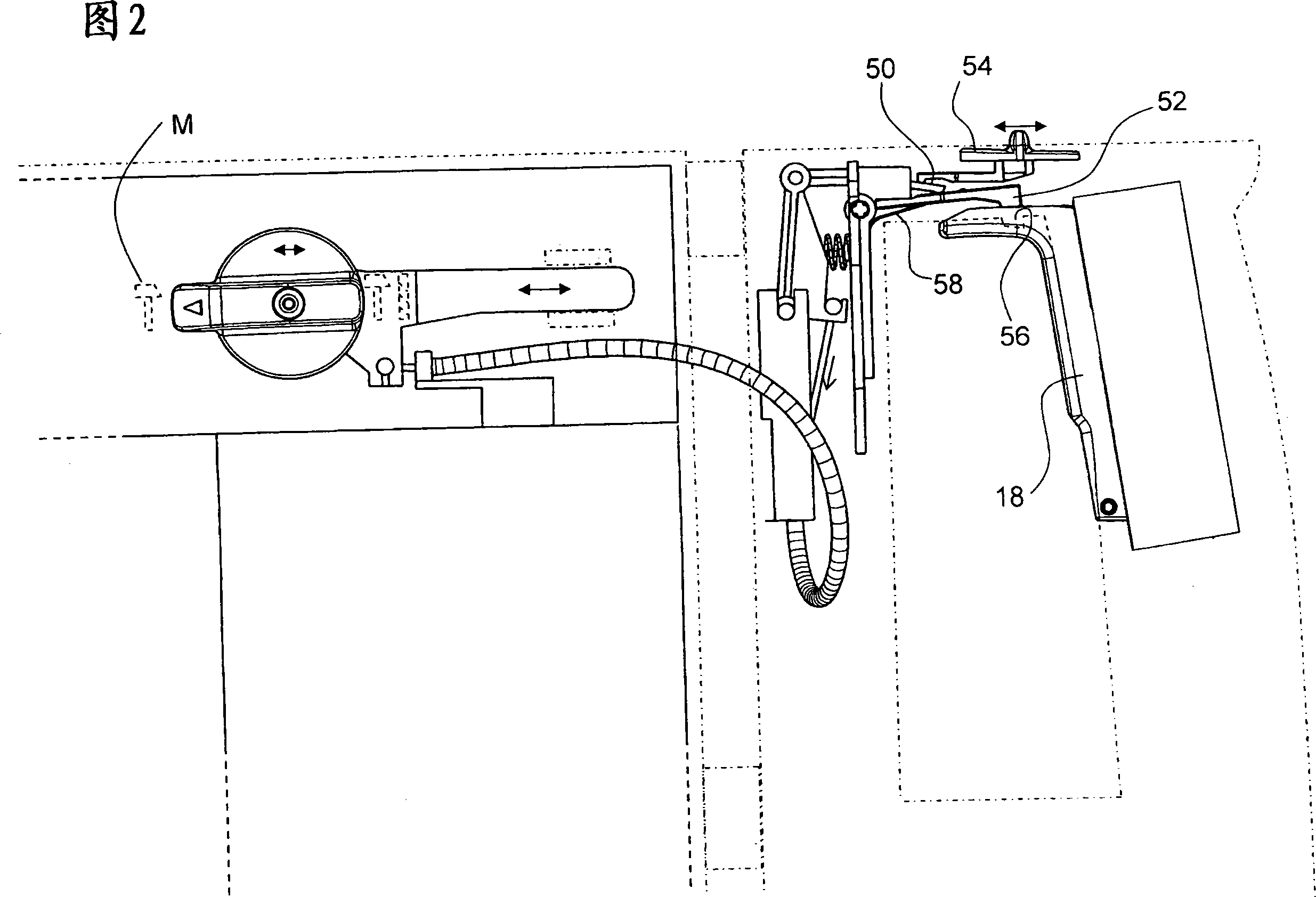

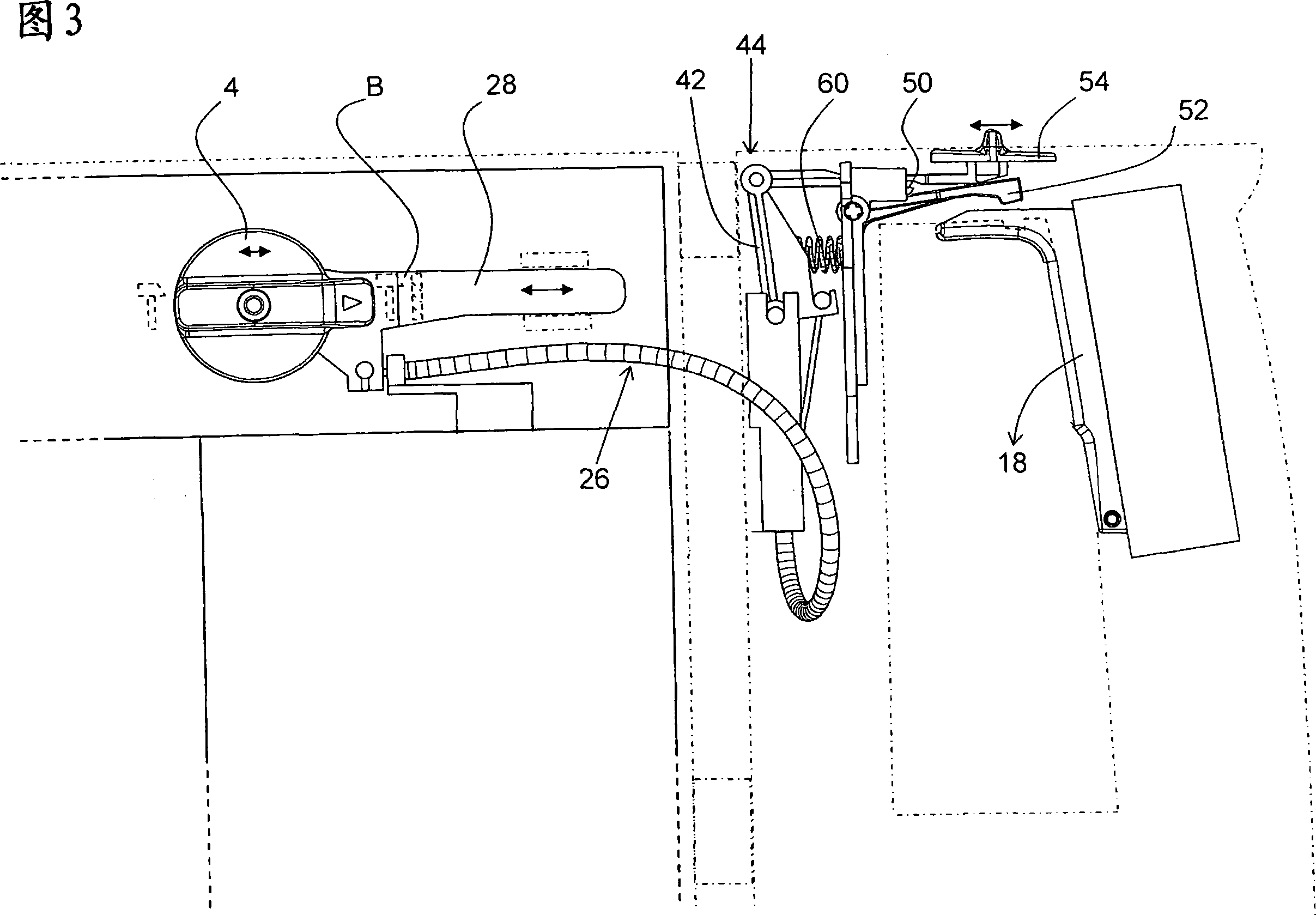

[0018] FIG. 1 partially shows a hand-held power tool 2 in the form of an electrically operated combination hammer. By means of the mode switch 4, the hand-held power tool can be switched between a chisel function with pure percussion operation and a drilling function, as indicated by a chisel position M and a drilling position B for the hammer percussion drilling or simple drilling.

[0019] The hand-held power tool 2 has a main housing 6 in which a motor unit 8 and a transmission unit 10 are accommodated. A further handle housing 12 is held on the main housing 6 with an intermediate layer of a damping device 14 having, for example, a spring mechanism not described in detail. The handle housing 12 forms a handle 16 which can be grasped by hand, and at the same time the switching pawl 18 of the motor switch 20 can be actuated by hand in order to actuate the motor unit 8 or the hand-held power tool 2 as a whole.

[0020] During operation, vibrations are generated at the main h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com