Glass fibre primary warping machine winding tension control method

A technology of tension control and glass fiber, which is applied to warping machines, manufacturing tools, textiles and papermaking, etc., to achieve the effects of small investment, balanced winding tension and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

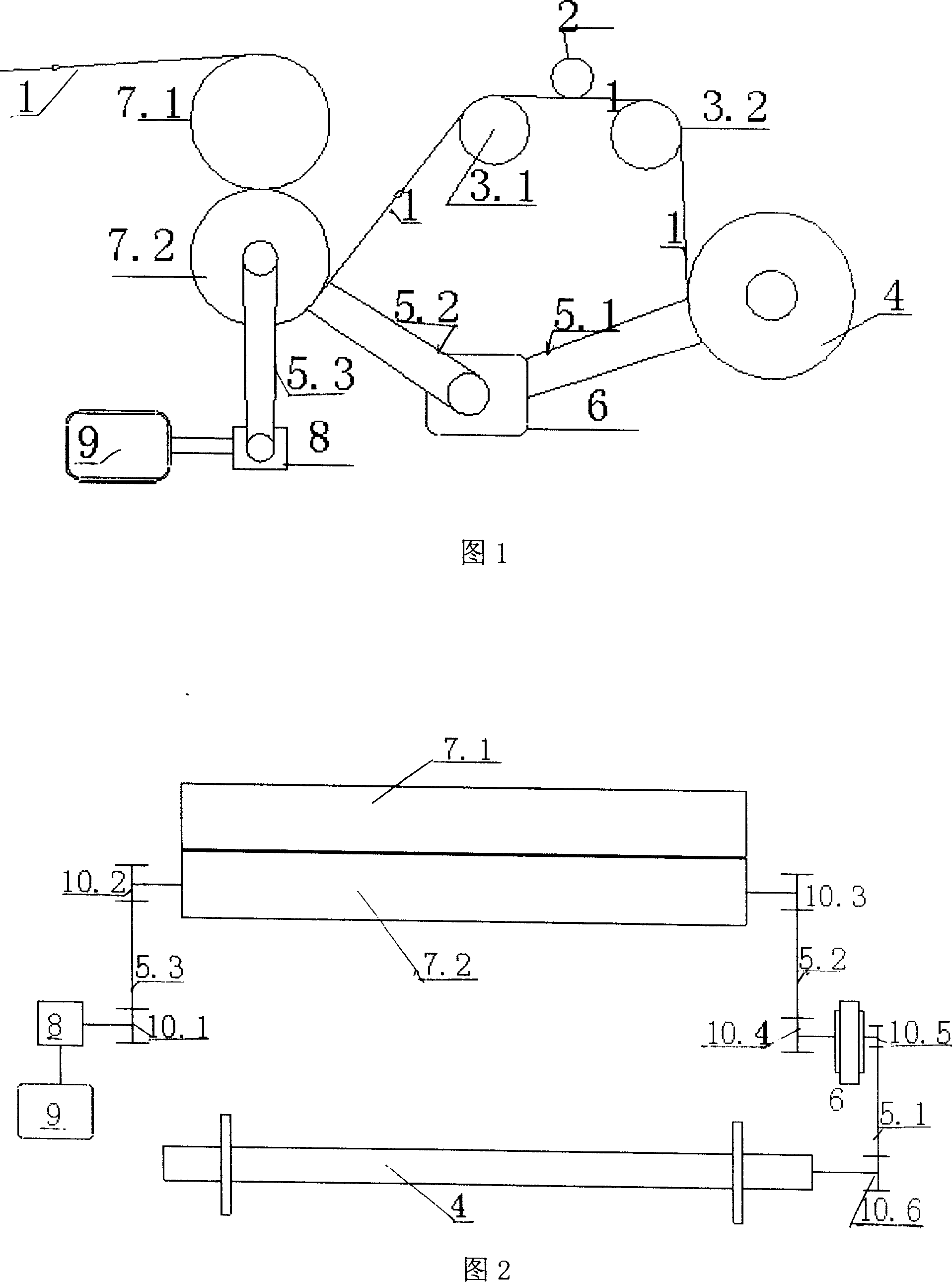

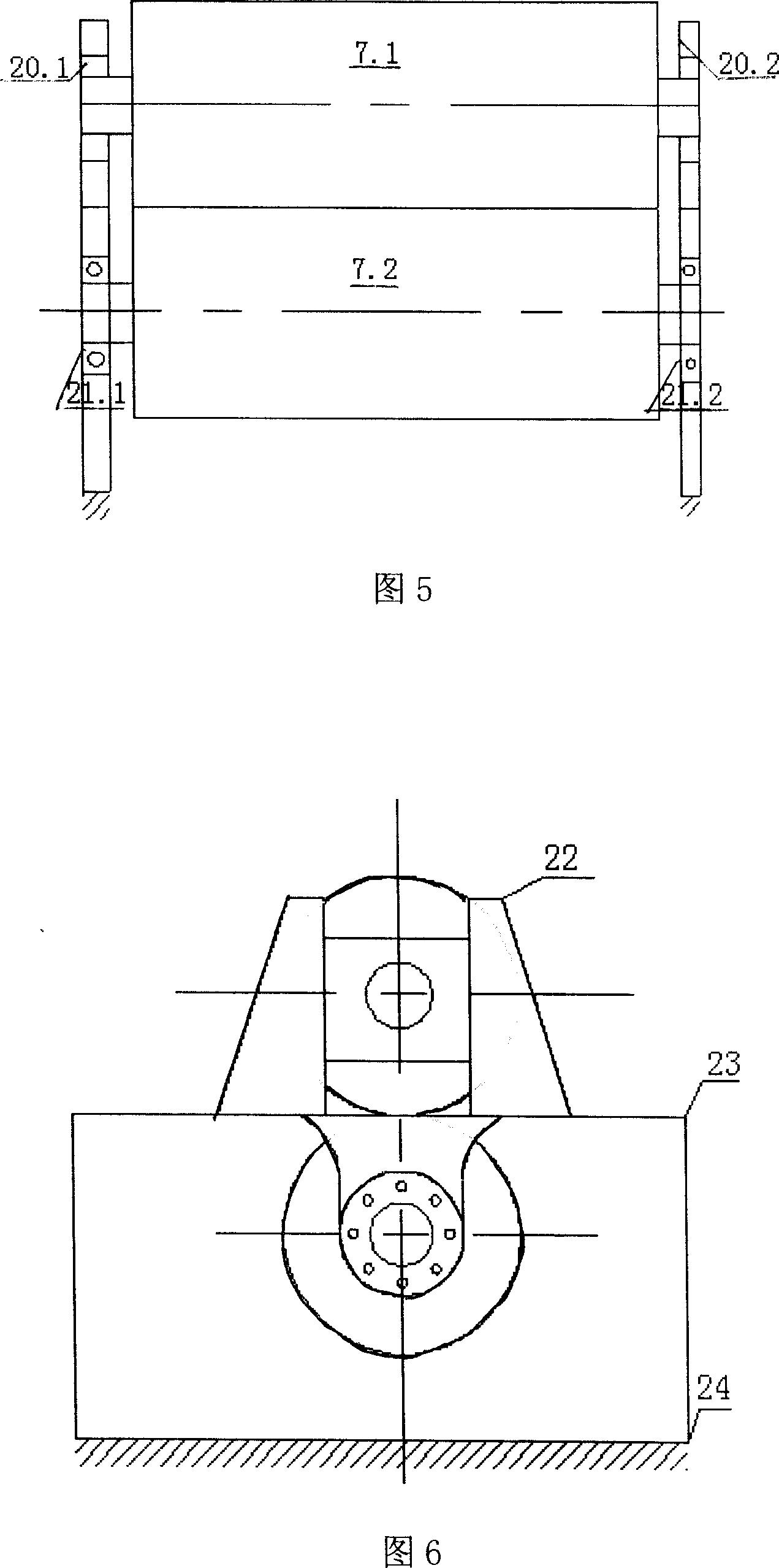

Method used

Image

Examples

Embodiment Construction

[0033] Take the SPAP120 warping process as an example:

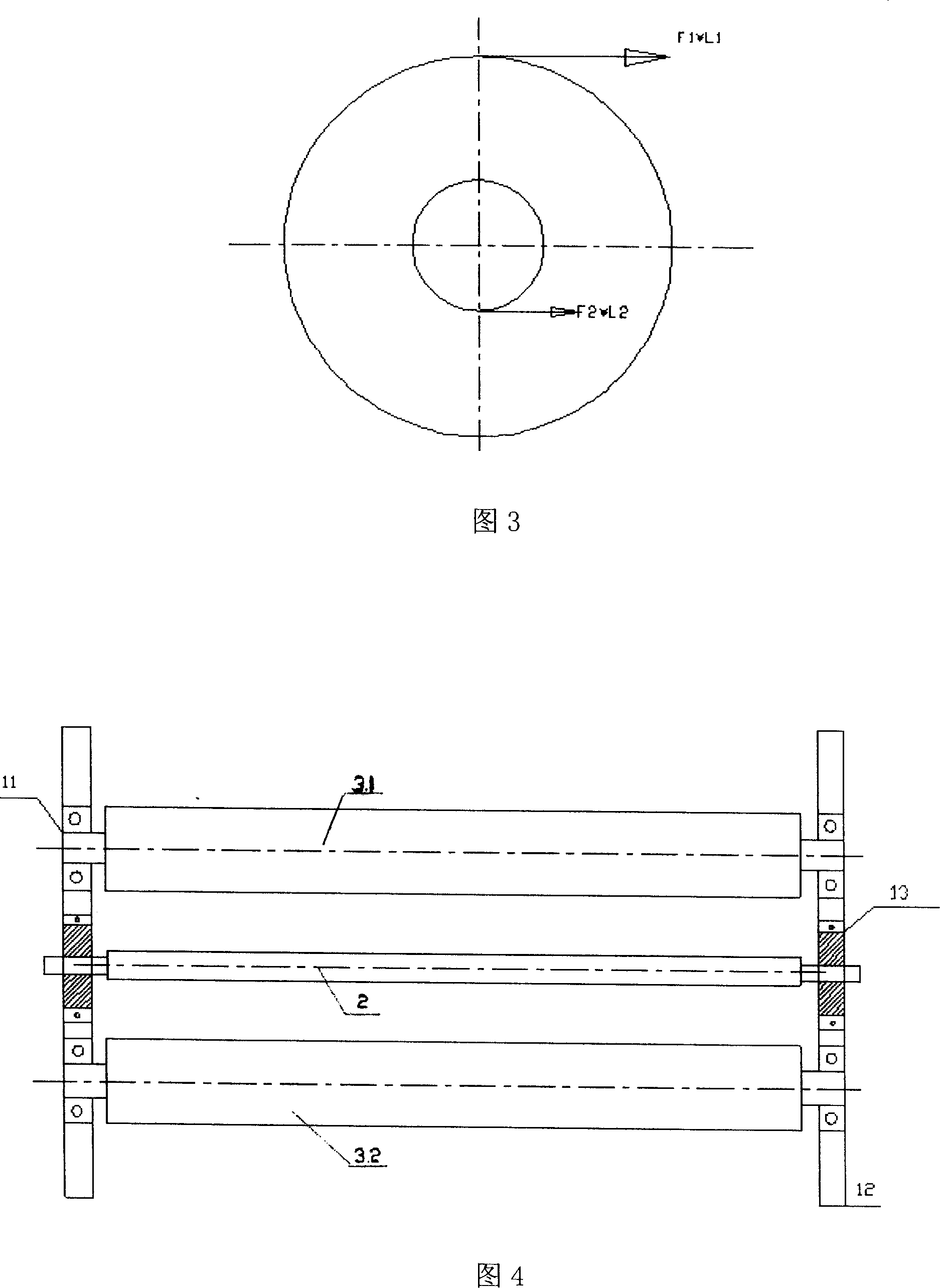

[0034] The glass fiber mesh SPAP120 has a total warp number of 2,000. During a warping process, first turn all the switches to the closed state, adjust the current of the potentiometer to 1A, and then start the speed-regulating motor to control the torque, and gradually adjust the speed of the speed-regulating motor. Speed to 800 rpm. It can be found that traction roller 7.1 and cloth guide roller 7.2 can be gradually adjusted in speed and finally stabilized at a certain speed. At this time, sheet yarn 1 is drawn out at a uniform speed under the static friction force to cloth guide roller 7.2 felt. The rewinding shaft 4 evenly rewinds the sheet yarn passing through the guide rollers 3.1, 3.2 and the tension adjustment roller 2 (fixed as shown in Figure 4) under the torque. As the diameter of the winding shaft becomes larger and larger, it can be gradually adjusted to 3A to achieve the production target. For example, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com