Direct water-taking water tank pressurization and water supply equipment

A technology for water supply equipment and water tanks, which is applied in the field of direct pressurization devices for tap water pipelines, can solve the problems of weak water supply stability, low flow regulation ability, and poor power saving effect, and achieves protection of municipal pipe network pressure, stable and reliable water supply, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

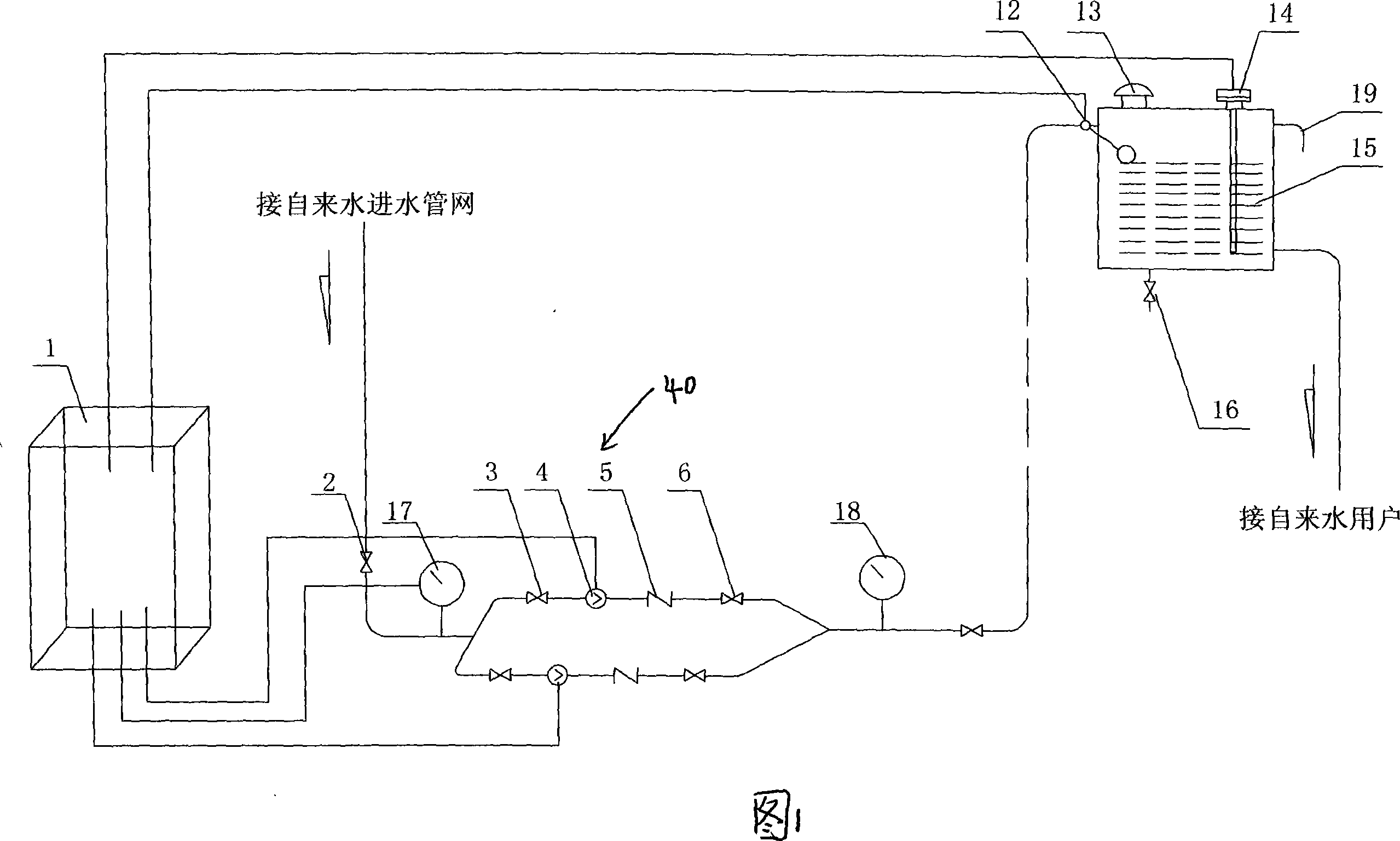

[0021] Embodiment: A water tank pressurized water supply equipment for direct water intake, including a control cabinet 1, a water tank 15, a liquid level transmitter 14, a water pump unit 40, and a first pressure gauge 17. A pressure gauge 17 is set at the water inlet end of the water pump unit 40, the water outlet end of the water pump unit 40 communicates with the water inlet of the water tank 15, the water outlet at the lower part of the water tank 15 communicates with the user end, and the water tank 15 supplies water to the user by gravity, the liquid level transmitter 14 is set in the water tank 15. The liquid level transmitter sends the liquid level signal in the water tank 15 to the control cabinet. The liquid level is divided into replenishment water level and full water level. The replenishment water level is below the full water level. water supply period;

[0022] 1) The water pump unit does not start during the peak water supply period, that is, the system does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com