An environment-friendly continuous oxygen blowing and moisture absorbing device

A hygroscopic device, an environment-friendly technology, applied in the field of environment-friendly continuous oxygen-blowing moisture-absorbing devices, can solve problems such as poor resistance, skin allergies, and aggravated wrinkle-related dermatitis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

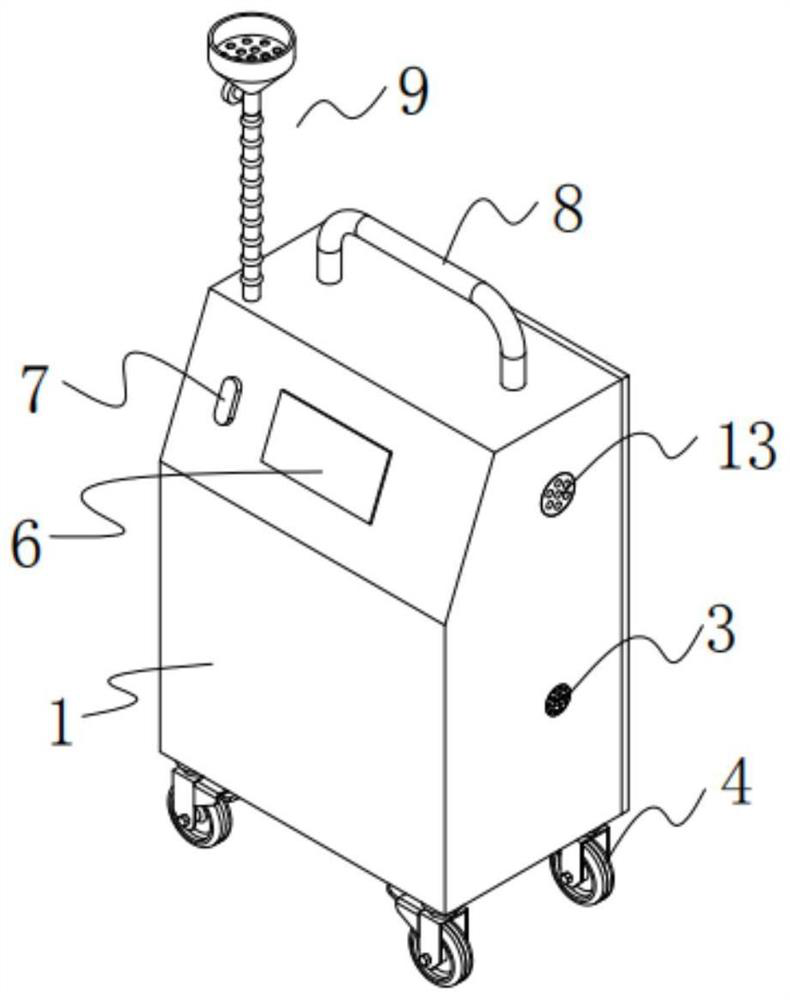

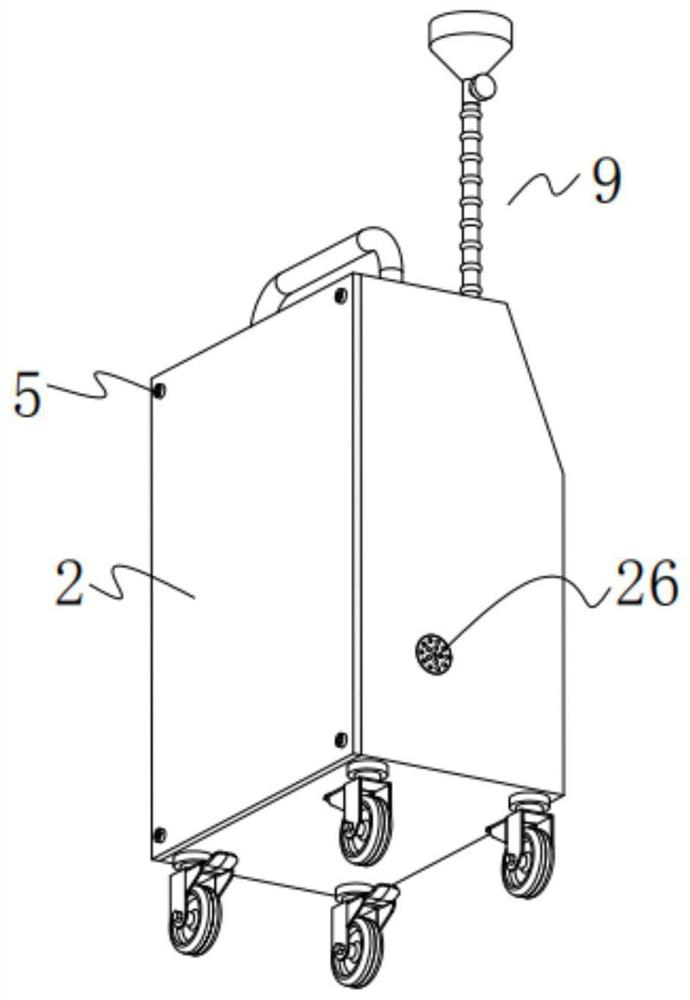

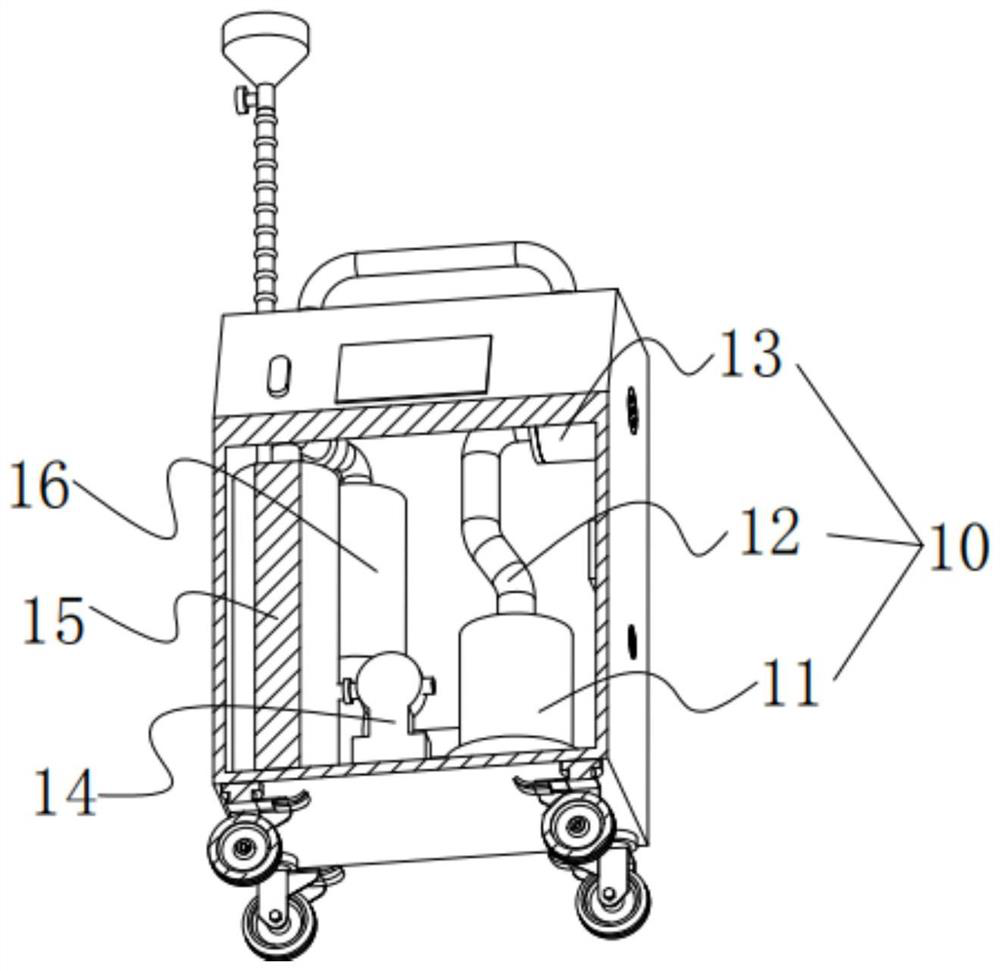

[0061] An environment-friendly continuous oxygen blowing moisture absorbing device, such as Figure 1-4 As shown, comprise shell 1, the top of described shell 1 is provided with oxygen blowing unit 9, and the inside of described shell 1 is provided with oxygen making unit 10 and is fixedly installed with oxygen storage tank 15;

[0062] Such as Figure 11-13 As shown, the oxygen blowing unit 9 includes a hose 27 installed through the top wall of the housing 1 and a metal shaped hose 36 sleeved outside the hose 27, and the hose 27 extends into the housing 1 is connected to the upper end of the oxygen storage tank 15, and the hose 27 protrudes from the outer end of the upper part of the shell 1 to communicate with a horn-shaped housing 38, and the horn-shaped housing 38 is connected to the oxygen storage tank 15. The caliber of one end connected to the hose 27 is smaller than the caliber of the other end, and the inner middle part of the horn-shaped housing 38 is sealed with a ...

Embodiment 2

[0083] The difference from Example 1 is that the surface and inner surface of the horn-shaped housing 38 and the surface of the partition 39 are provided with a protective layer, and the protective layer is prepared by the following method:

[0084] Take the following raw materials and weigh them by weight: 12 parts of porcelain powder, 10 parts of titanium dioxide powder, 13 parts of nano-silver powder, 8 parts of copper rosinate, 12 parts of phenolic resin, 3 parts of glycerin, 2 parts of alcohol ester twelve, high-carbon alcohol fat 1 part of ester complex and 30 parts of ethanol;

[0085] S1, adding the weighed copper rosinate, glycerin, alcohol ester dodeca, higher alcohol fatty acid ester complex and ethanol into the mixer and stirring for 20min, the stirring speed is 600r / min, and a mixed solution is obtained;

[0086] S2, adding porcelain powder, titanium dioxide powder, nano-silver powder and phenolic resin into a ball mill for fine grinding until the particle diamete...

Embodiment 3

[0092]The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0093] Take the following raw materials and weigh them by weight: 14 parts of porcelain powder, 11 parts of titanium dioxide powder, 14 parts of nano-silver powder, 9 parts of copper rosinate, 14 parts of phenolic resin, 4 parts of glycerin, 3 parts of alcohol ester twelve, high-carbon alcohol fat 2 parts of acid ester complex and 40 parts of ethanol;

[0094] S1. Add the weighed copper rosinate, glycerin, alcohol ester dodeca, higher alcohol fatty acid ester complex and ethanol into the mixer and stir for 25min, and the stirring speed is 700r / min to prepare a mixed solution;

[0095] S2, adding porcelain powder, titanium dioxide powder, nano-silver powder and phenolic resin into a ball mill for fine grinding until the particle diameter is not greater than 40um to obtain a mixed powder material;

[0096] S3. Put the mixed solution prepared in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com