Oil smoke suction machine and gas oven integrated type internal combustion oven

A gas stove, integrated technology, applied in the direction of oil fume removal, household stove, heating fuel, etc., can solve the problems of poor energy conservation and environmental protection, low thermal efficiency, complex control, etc., to achieve convection and radiation loss reduction, full gas combustion , reduce the effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

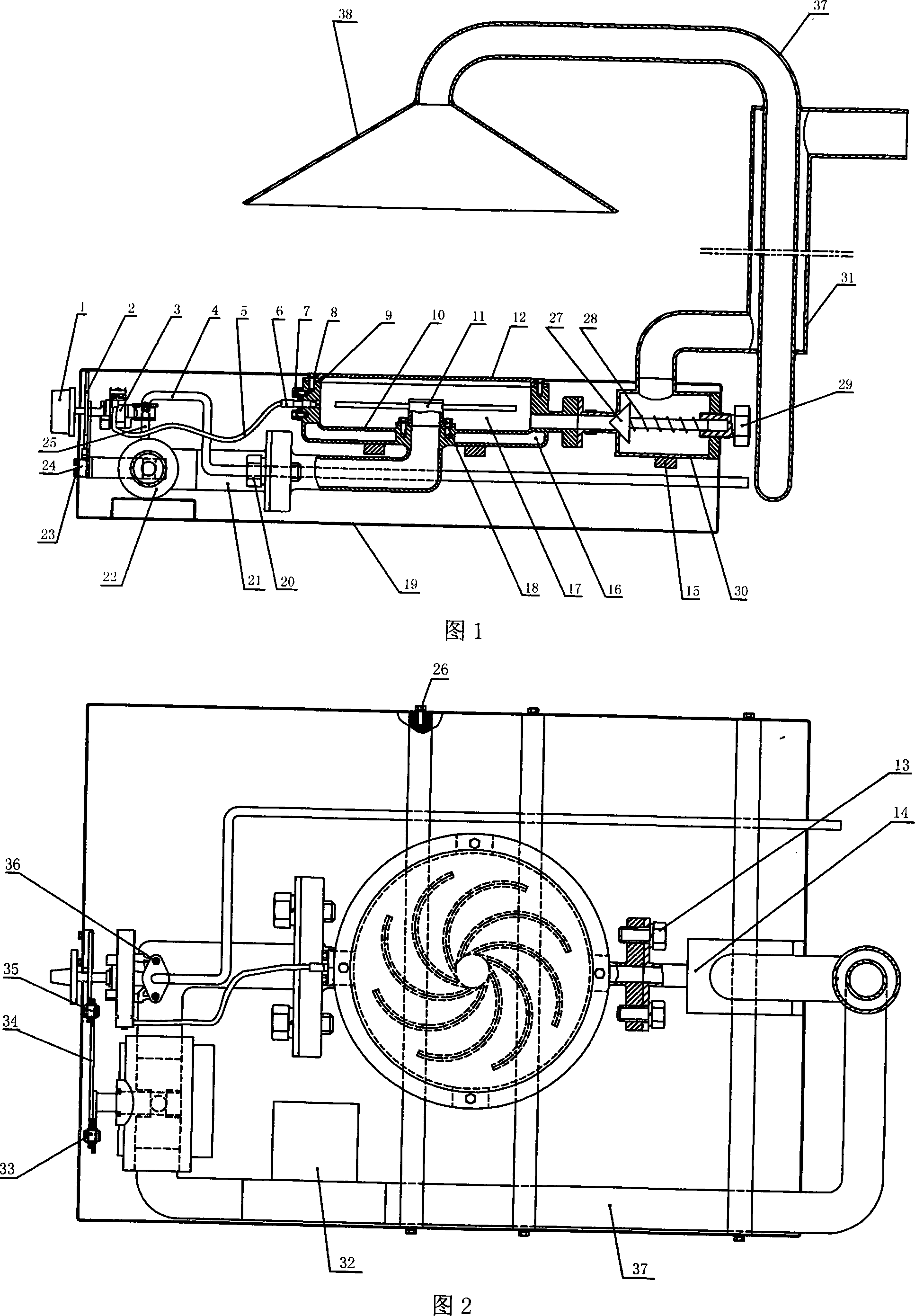

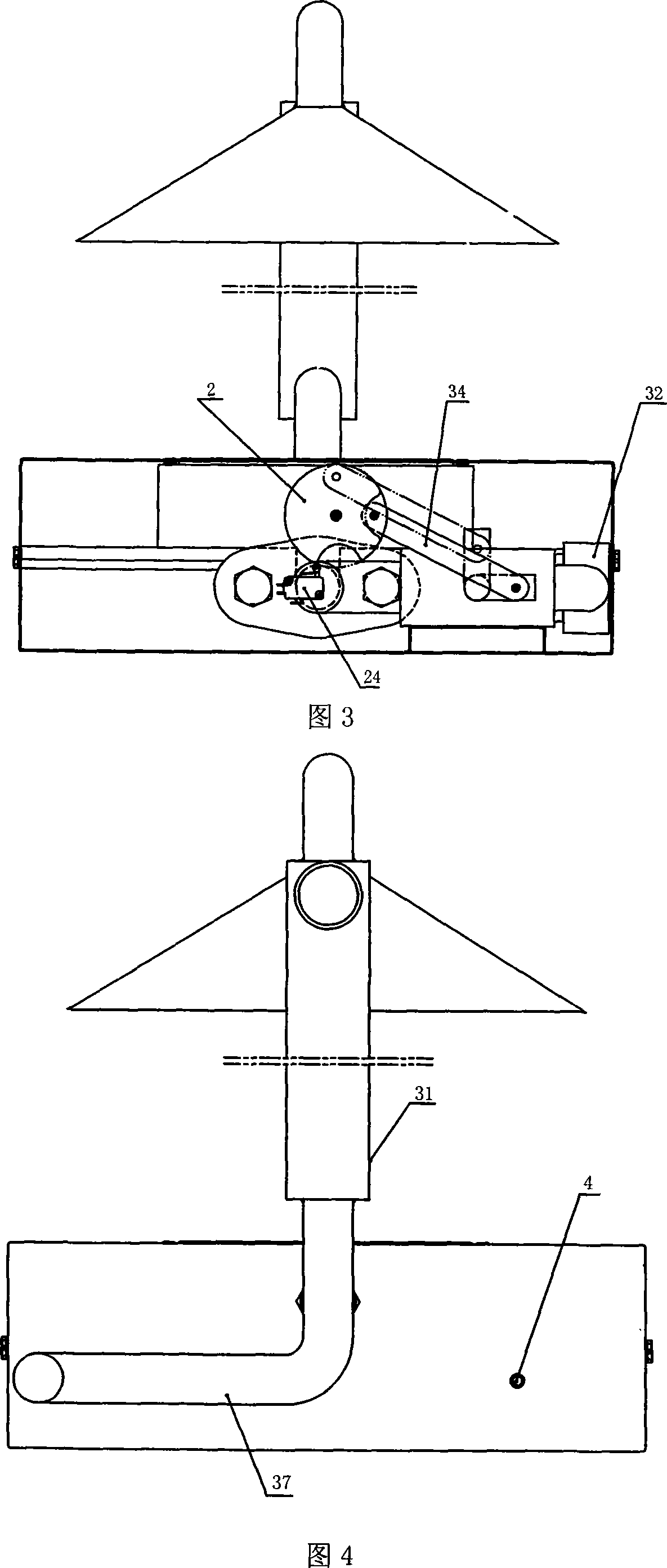

[0012] In the implementation of the present invention, its main structural components include knob 1, cam 2, igniter assembly 3, gas inlet pipe 4, ignition switch lead wire 5, spark head 6, screw 7, screw 8, sealing gasket 9, furnace body 10 , burner 11, cover plate 12, bolt 13, exhaust valve 14, support plate 15, furnace inner cavity 16, combustion chamber 17, screw 18, shell 19, bolt 20, intake pipe 21, intake valve 22, Screw 23, micro switch 24, gas pipeline 25, screw 26, exhaust valve core 27, spring 28, adjustment screw 29, exhaust valve body 30, exhaust pipe 31, fan 32, pin 33, connecting rod 34, Pin 35, screw 36, intake pipe 37 and gas collector 38. The function and connection relationship of each component will be further described below in conjunction with the accompanying drawings.

[0013]When the present invention is implemented, the knob 1 is fixedly connected with the cam 2 through its rotating shaft, the knob 1 is turned, the cam 2 rotates synchronously, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap