Active type fume exhauster

A range hood, active technology, applied in the direction of oil fume removal, heating method, household heating, etc., can solve the problems of large power consumption, inconvenient operation, difficult to completely eliminate the oil fume, etc., to achieve convenient collection of waste oil and reduce heat Baking, cooking environment bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

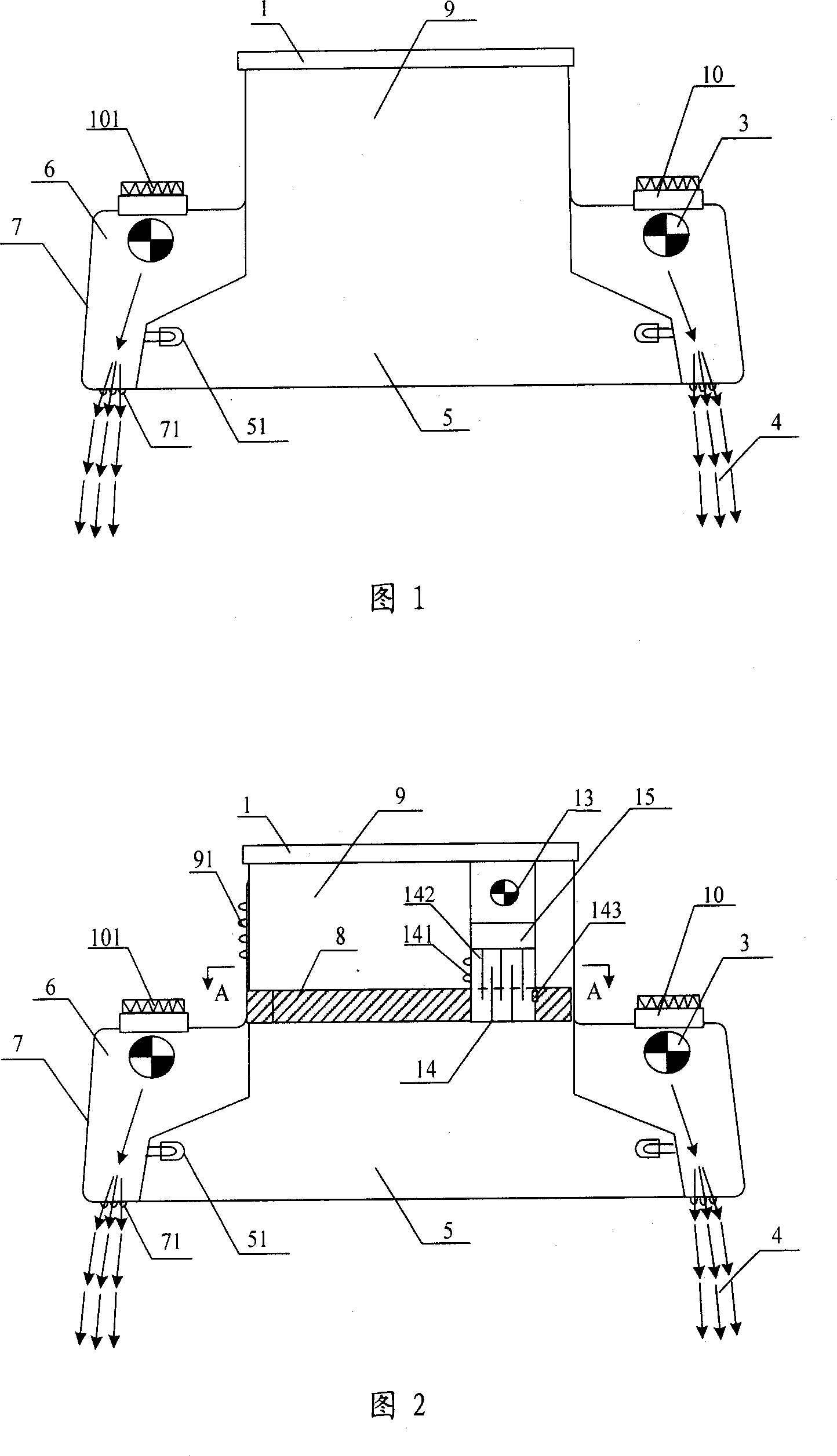

[0026] As shown in Figure 1, it includes a box body 7, the bottom of the box body 7 is recessed with a smoke collection chamber 5, a hollow cavity 6 is formed between the outer casing of the box body 7 and the smoke collection chamber 5, and the left and right sides of the hollow cavity 6 are respectively provided with The air supply inlet 10, the air supply inlet 10 is respectively equipped with a blower fan 3 and a fresh air filter device 101, the hollow cavity 6 is located around the bottom of the box body 7 and is provided with an air supply outlet 71 that can form a wind wall 4, and the smoke collection cavity 5 An air exhaust port 1 is opened on the top, which passes through the box body 7 and extends to the outside of the box body 7 , and an air exhaust duct 9 is formed between the air exhaust port 1 and the top of the smoke collecting chamber 5 .

[0027] In the running state, the blower 3 sends the fresh air into the hollow cavity 6 from the air supply inlet 10 after b...

Embodiment 2

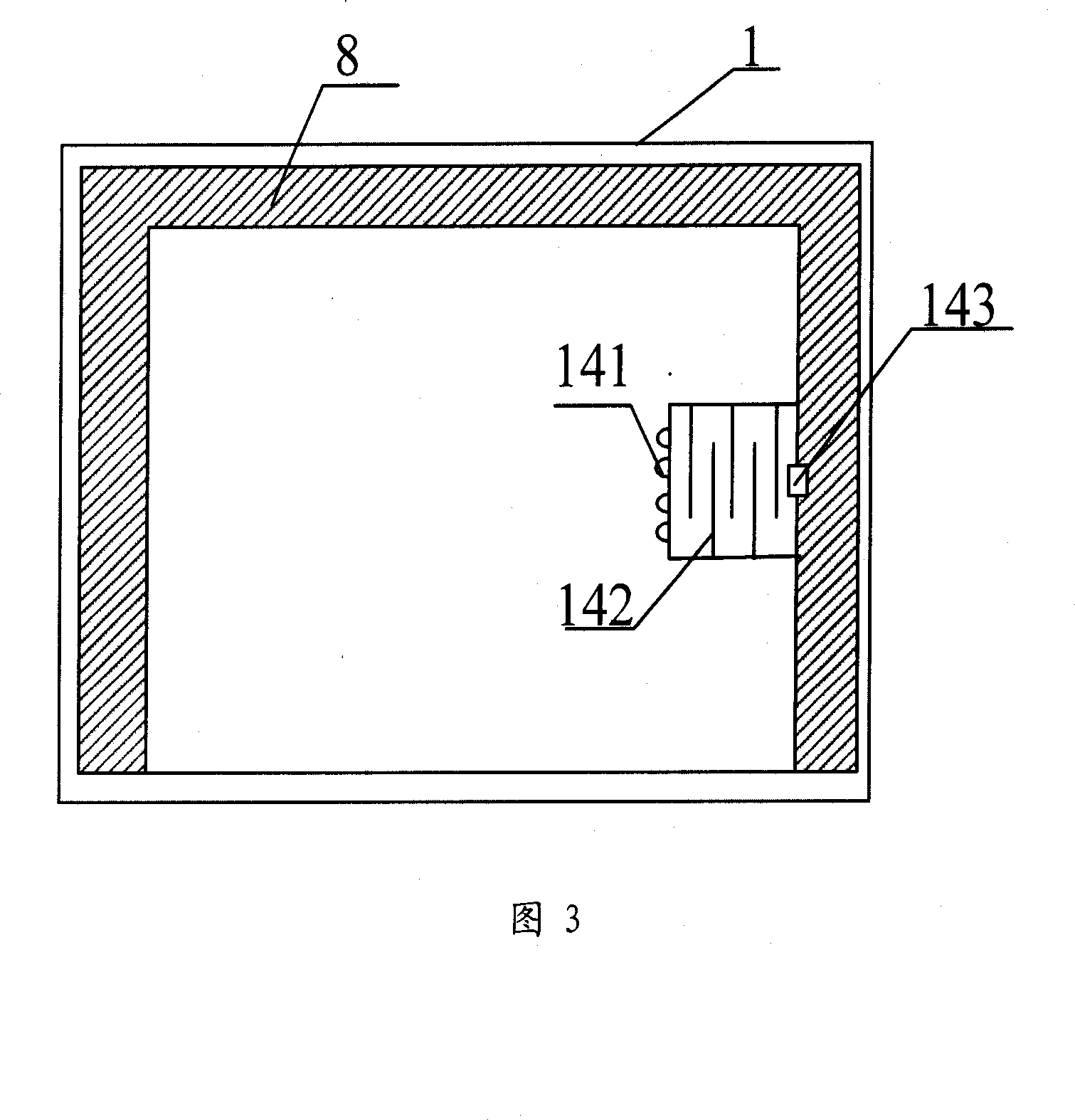

[0034] As shown in Figures 2 and 3, in order to further improve the smoke exhaust effect and solve the problem of waste oil collection, this embodiment is based on Embodiment 1, and an exhaust fan 13 is arranged in the exhaust duct 9, and the bottom of the exhaust fan 13 is arranged There is a fume separator 14 and a plenum 15 , and the fume separator 14 communicates with the exhaust fan 13 through the plenum 15 . The bottom edge of the exhaust duct 9 is provided with a waste oil collection tank 8, which is in close contact with one side of the oil fume separator 14. The side of the oil fume separator 14 is provided with oil fume inlet holes 141, and the inside is interlaced with oil fume separation plates 142. An oil discharge port 143 is opened at the contact of the oil collection tank 8 .

[0035] As described in Embodiment 1, the oil fume is driven out of the exhaust outlet 1 by the air pressure difference formed by the wind wall 4 . 141 enters the oil fume separator 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com