Light conducting board

A light guide plate and light guide layer technology, which is applied in the field of light guide plates, can solve problems such as high cost and complicated assembly, and achieve the effect of reducing costs and omitting reflective sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

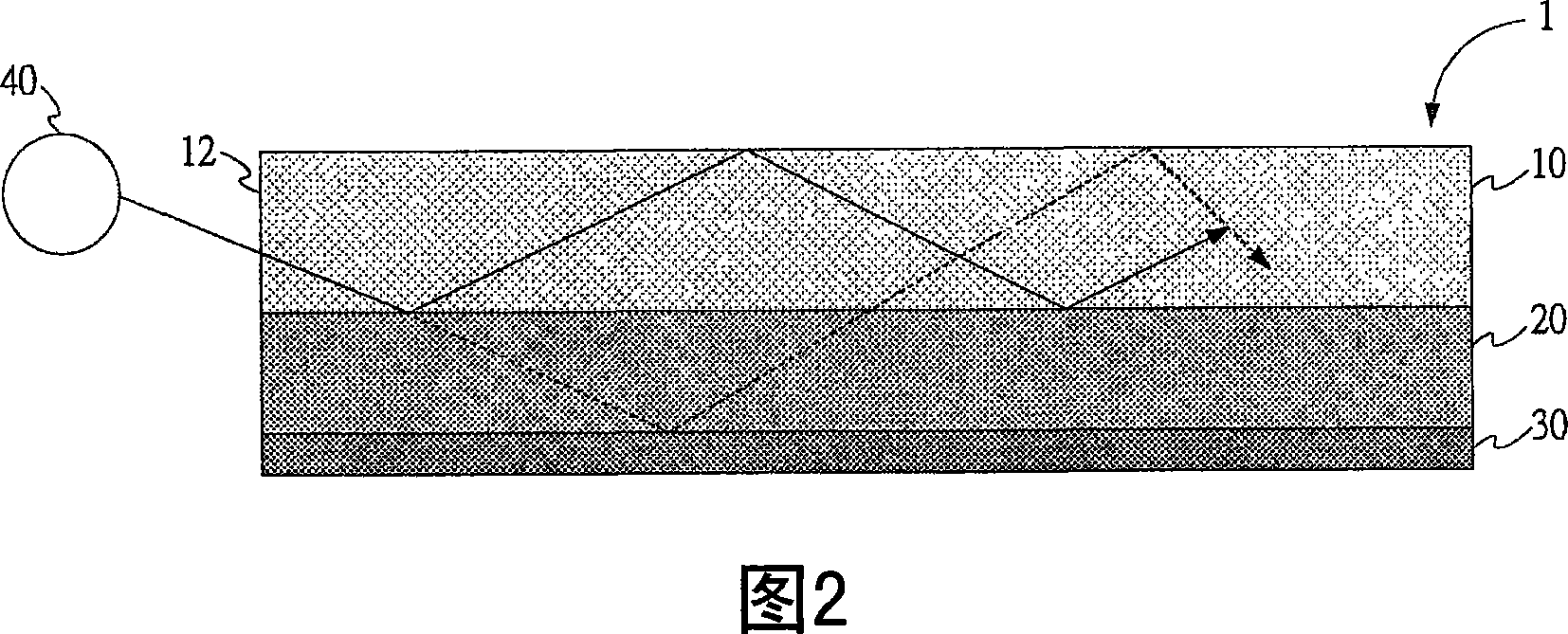

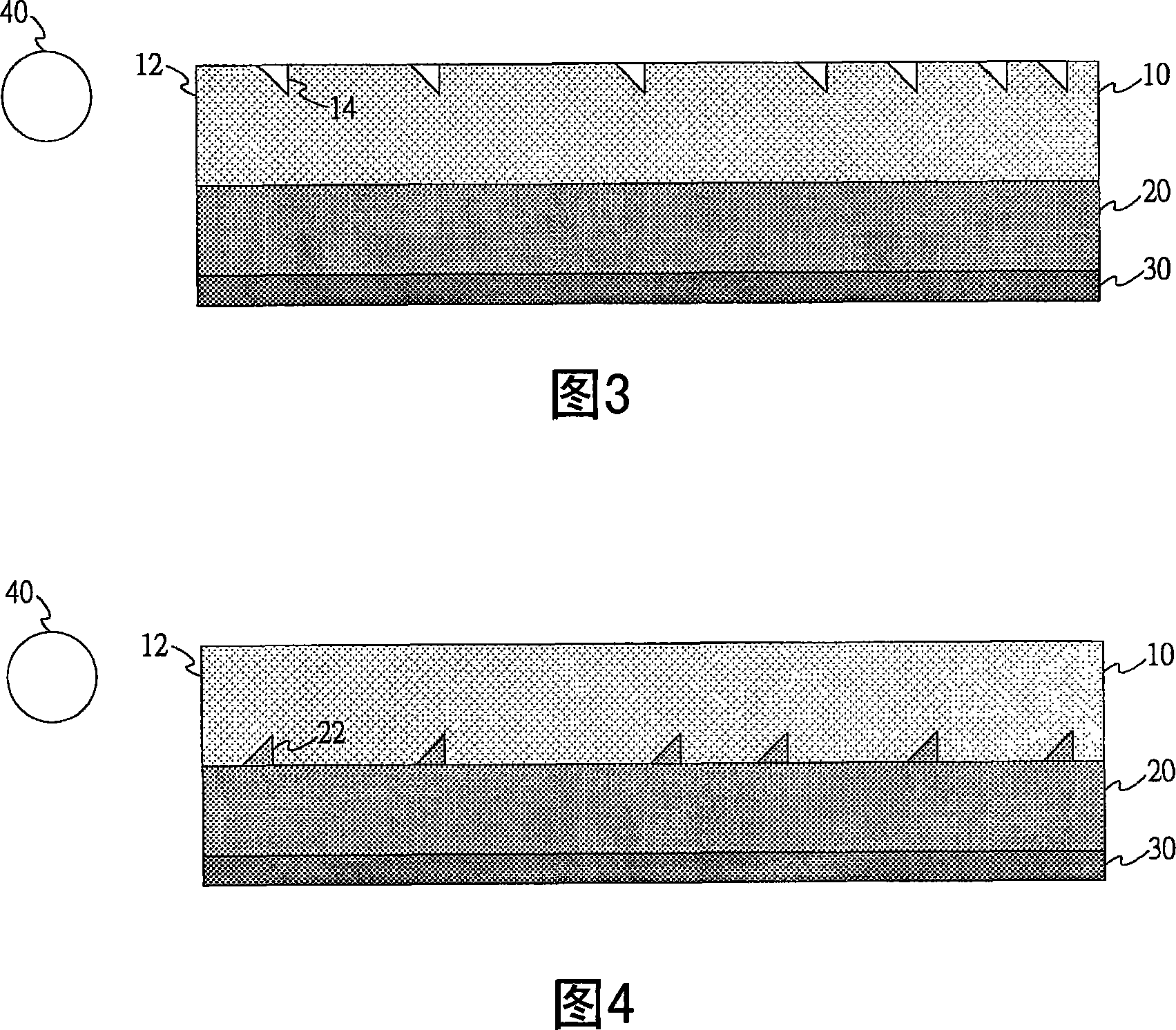

[0027] FIG. 2 is a schematic diagram of the first embodiment of the light guide plate of the present invention. The light guide plate 1 proposed by the present invention is used to transmit incident light 40 , and the light guide plate 1 includes: a first light guide layer 10 , a second light guide layer 20 , and a surface layer 30 .

[0028] The first light guiding layer 10 has an end surface 12 through which incident light 40 enters the first light guiding layer 10 . The second light guiding layer 20 is formed under the first light guiding layer 10 , and the refractive index of the second light guiding layer 20 is smaller than that of the first light guiding layer 10 . As shown in FIG. 2 , when the incident light 40 enters from the end surface 12 of the first light guiding layer 10 and reaches the interface between the first light guiding layer 10 and the second light guiding layer 20, most of the incident light 40 will Due to total reflection, it is conducted in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com