Step drying type garbage pusher

A technology for pushing material and garbage, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of uneven quantity, grate failure, and garbage cannot be fully burned, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

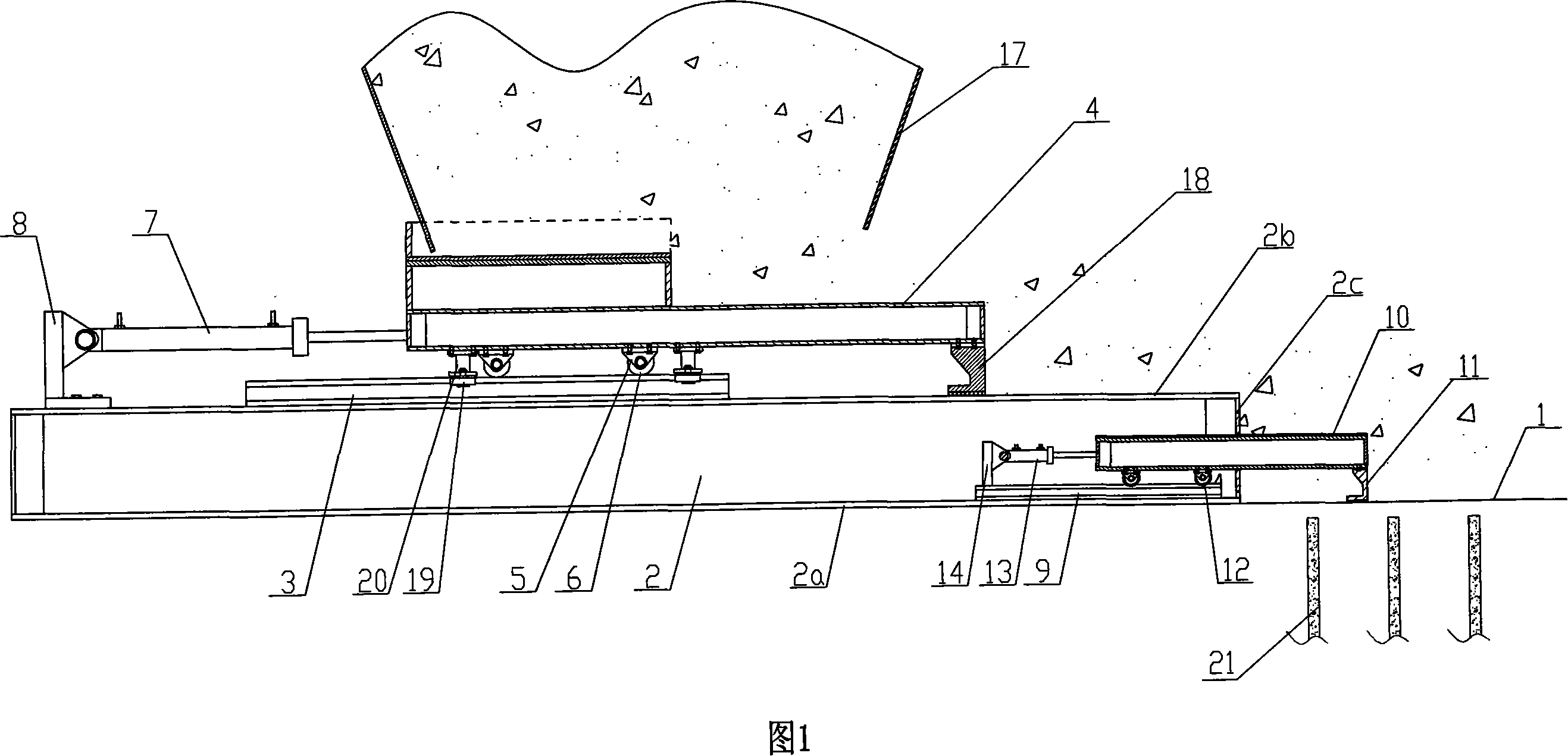

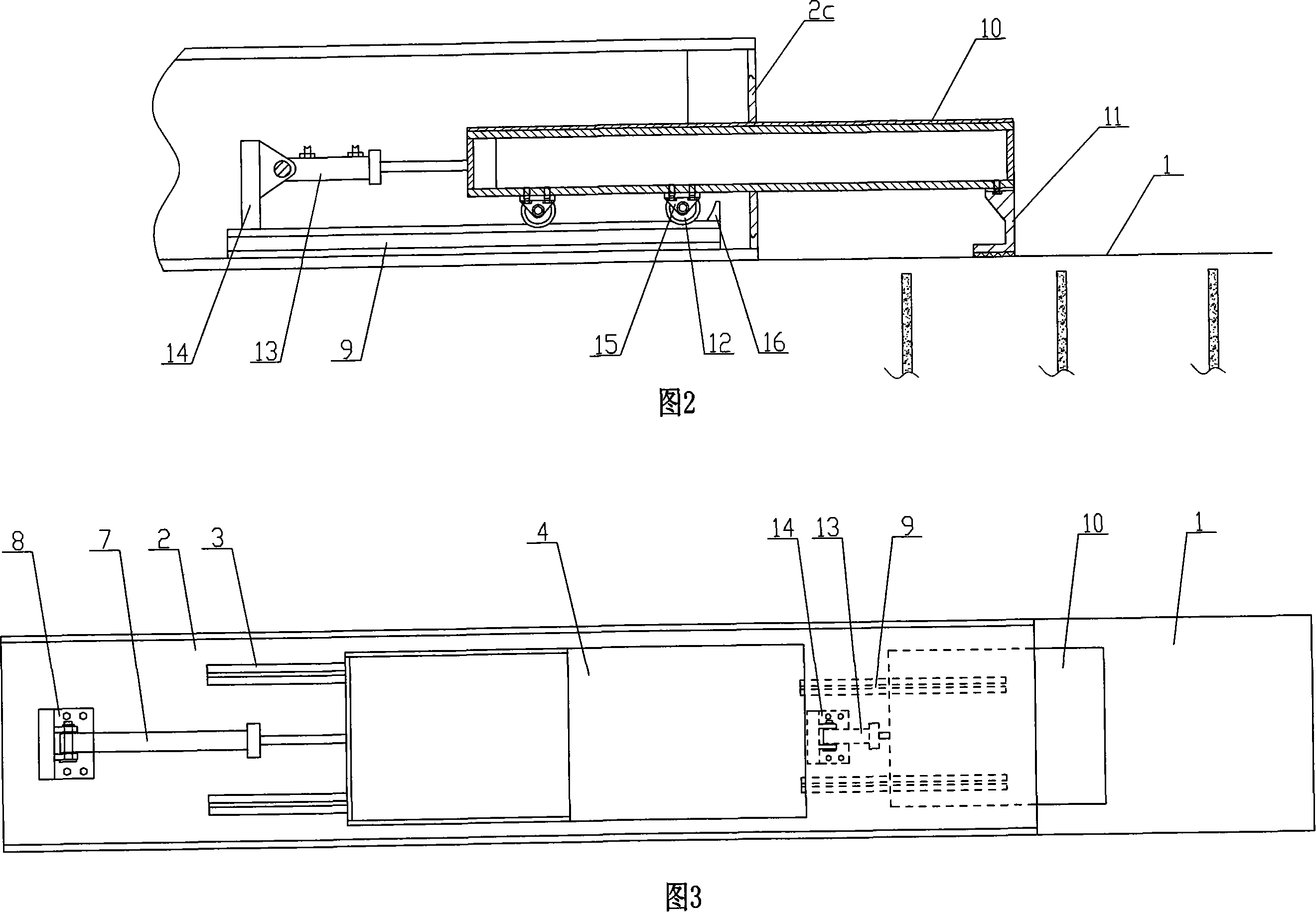

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0015] As shown in Figure 1 and Figure 3, the top plate 2b of the fixed chassis 2 is a flat plate structure parallel to the horizontal plane, and two rails 3 are arranged in parallel at the position behind the middle of the top plate 2b of the fixed chassis 2, and the fixed chassis 2 top plate 2b The middle part of the rear end is fixed bearing 8 by bolt, and the tail end of hydraulic cylinder 7 parallel with track 3 is connected with bearing 8, and its piston rod stretches out forward, and is fixedly connected with pushing material trolley 4 tail ends. Pushing material trolley 4 is positioned at the below of silo 17, has the car body of upper and lower layer length unequal, and wherein upper strata car body is aligned with the rear end of lower strata car body, and the upper surface of upper strata car body is positioned at the front of upper strata car body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com