Engine

An engine and fuel technology, applied in combustion engines, engine control, machines/engines, etc., to solve problems such as deterioration of exhaust emissions and deterioration of fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings.

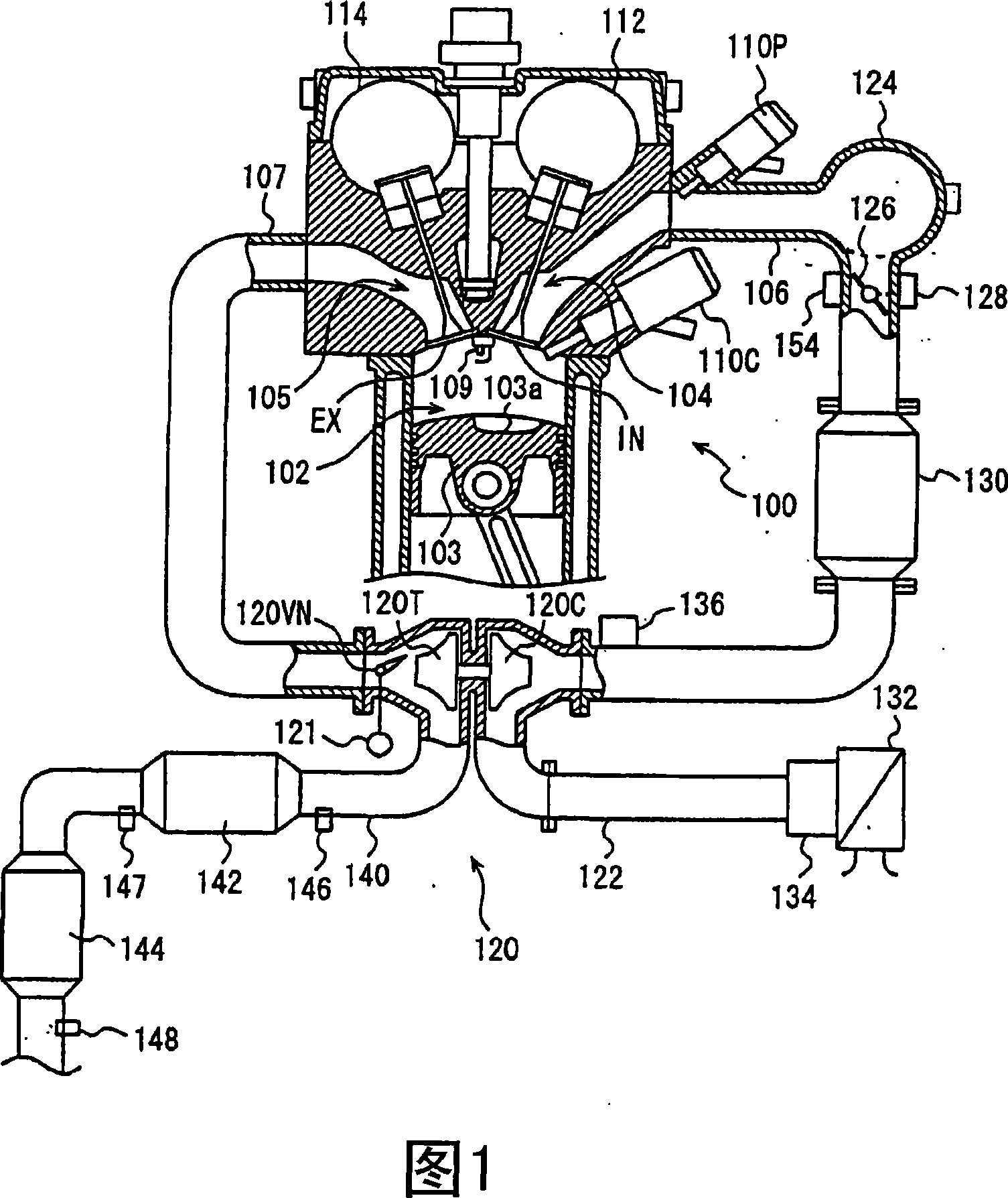

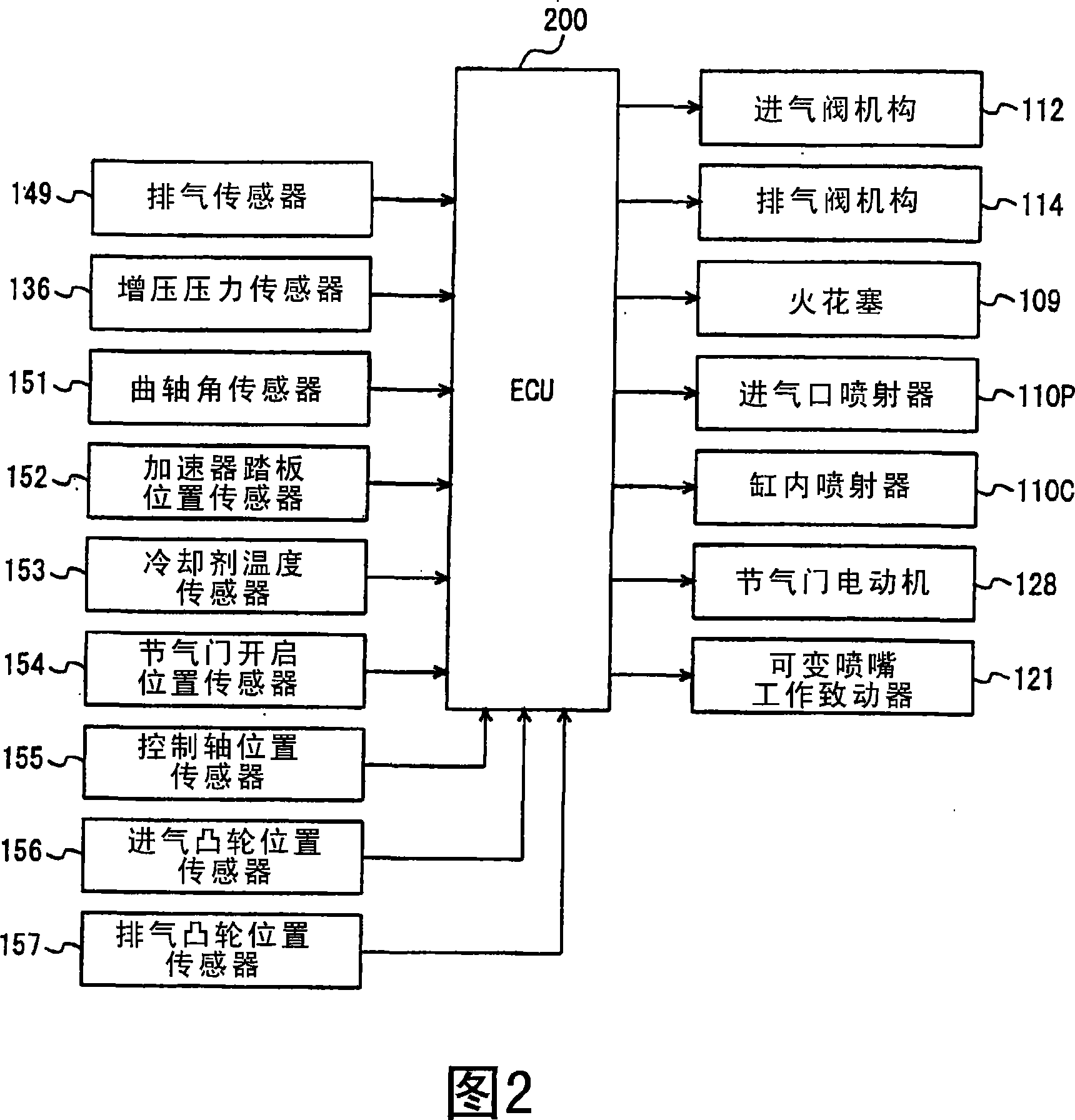

[0028] Figure 1 schematically shows a system structure, which roughly illustrates a lean-burn engine equipped with a supercharger, in which the engine uses a turbocharger as a supercharger, and according to the first and second aspects of the present invention The embodiment is applied to the system. The engine 100 shown in FIG. 1 is configured as a multi-cylinder engine (for example, a four-cylinder engine, but only one cylinder is shown in FIG. 1), and an air-fuel mixture is combusted in each combustion chamber 102 to cause the piston 103 to reciprocate, thereby The crankshaft (not shown) gains power. Note that the engine may not have a supercharger.

[0029] Each combustion chamber 102 of the engine 100 communicates with an intake port 104 and an exhaust port 105. The intake manifold 106 is connected to the intake port 104. The exhaust manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com