Motor driven pumping unit with two dish surfaces

A motor-driven, pumping unit technology, applied in the direction of machines/engines, electric components, electromechanical devices, etc., can solve problems such as limited effects, and achieve the effect of convenient speed regulation, realization of renovation and simplification of mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

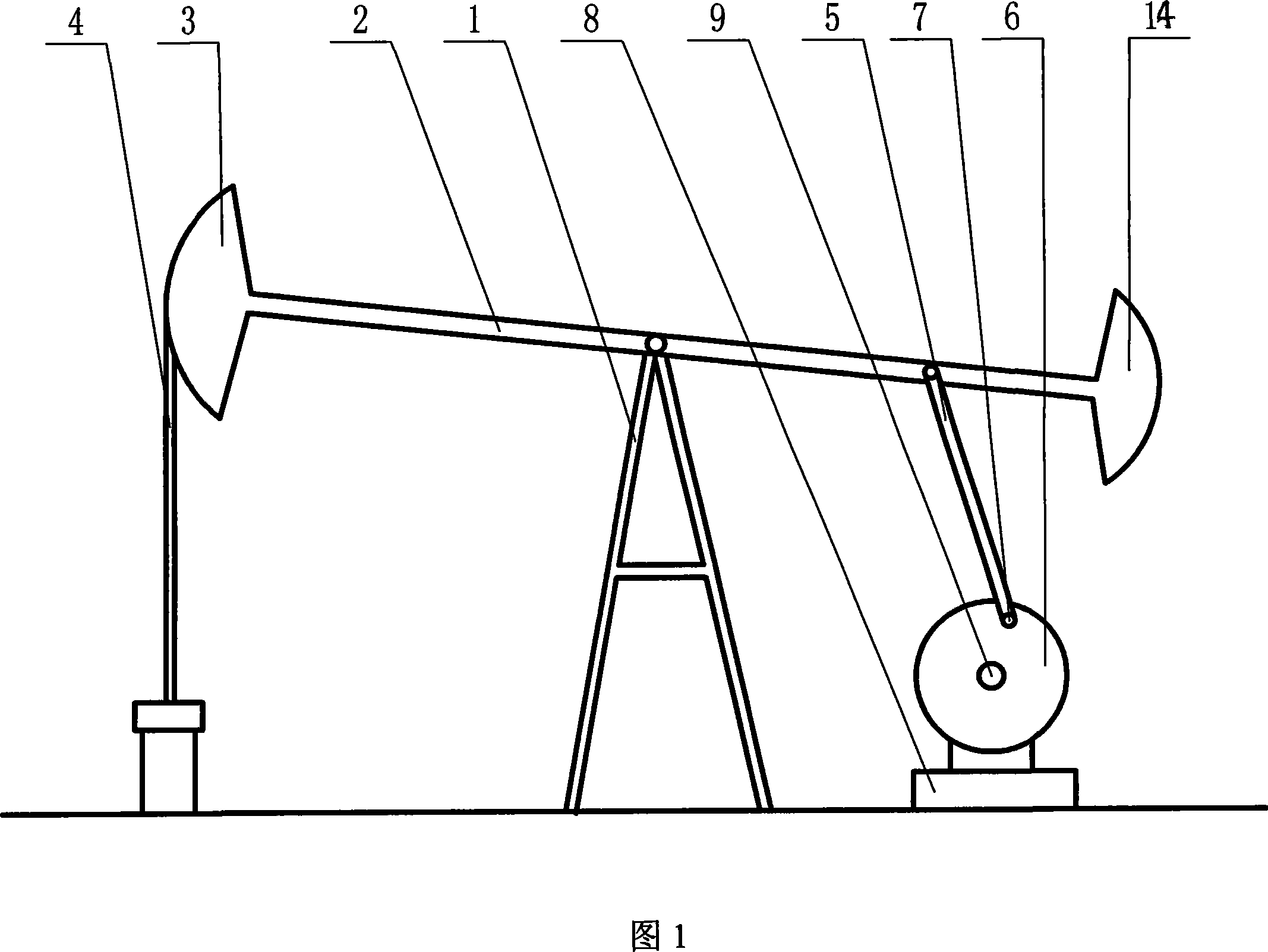

[0018] As shown in Fig. 1, it is an embodiment of a double-disk motor-driven pumping unit of the present invention. A double-disc motor-driven pumping unit, comprising a frame 1, a beam 2 arranged on the frame 1, a donkey head 3 arranged at one end of the beam 2, and the other end of the beam 2 is usually provided with a matching The weight 14, the pump rod 4 arranged under the donkey head 3 and connected with the donkey head 3, the connecting rod 5 arranged on the other side of the beam 2, the bottom of the connecting rod 5 is provided with a double-disk motor 6, and the double-disk motor 6 The disc surfaces on both sides are symmetrically provided with supporting shafts 7 and are hingedly connected with the two connecting rods 5 respectively, and the upper ends of the two connecting rods 5 are respectively hinged with the traveling beam 2;

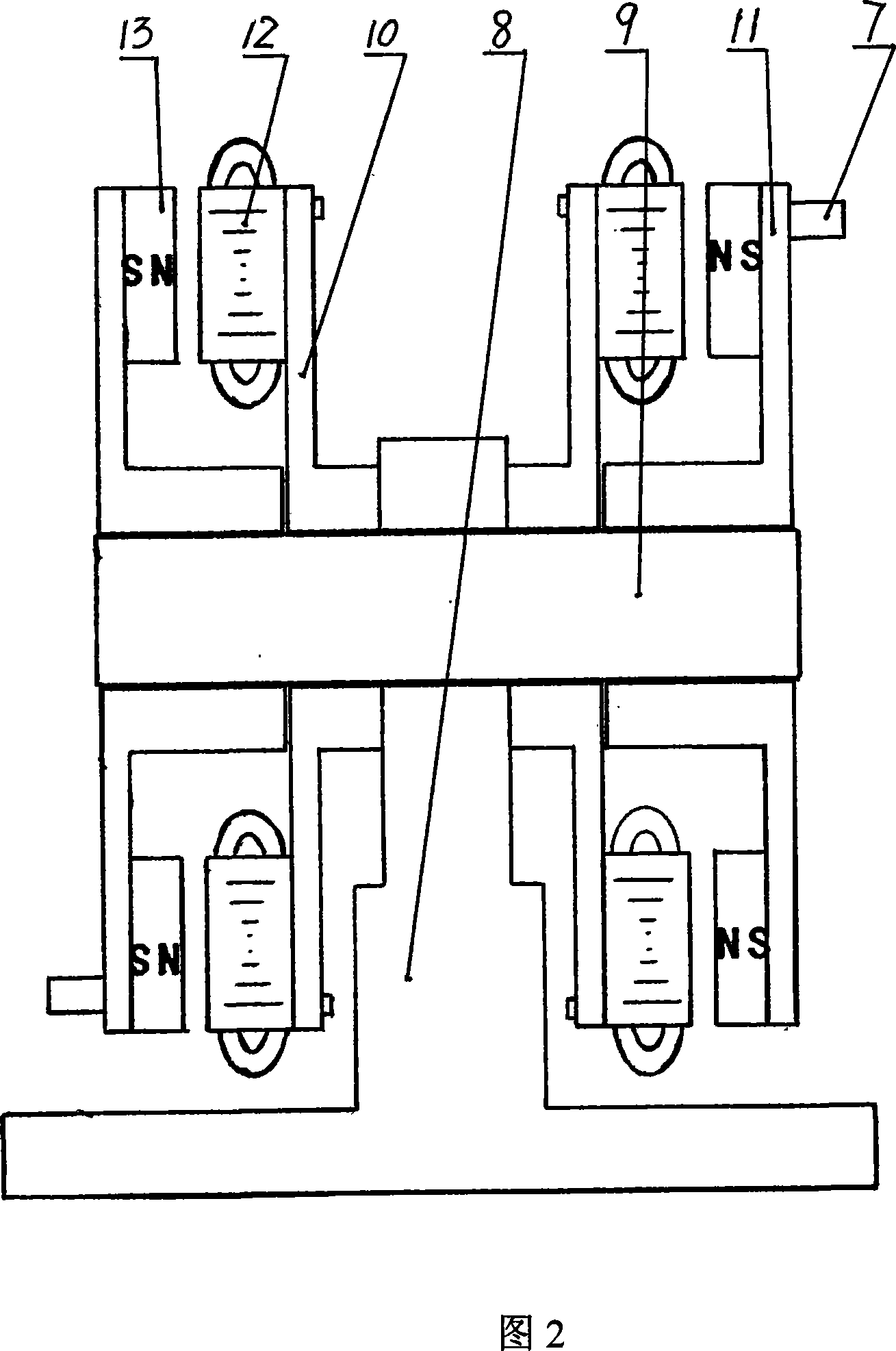

[0019] As shown in Figures 1 and 2, a double-disc motor 6 includes a base 8, a main shaft 9 arranged on the base 8, two disc stators 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com