Gear transmission motor and robot gear transmission motor

A technology of gear transmission and motor, applied in the direction of transmission box, transmission parts, belt/chain/gear, etc., can solve the problems of high cost and lack of versatility, achieve large forming space, reduce assembly hours, and be easy to assemble. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An example of an embodiment of the present invention will be described in detail below with reference to the drawings.

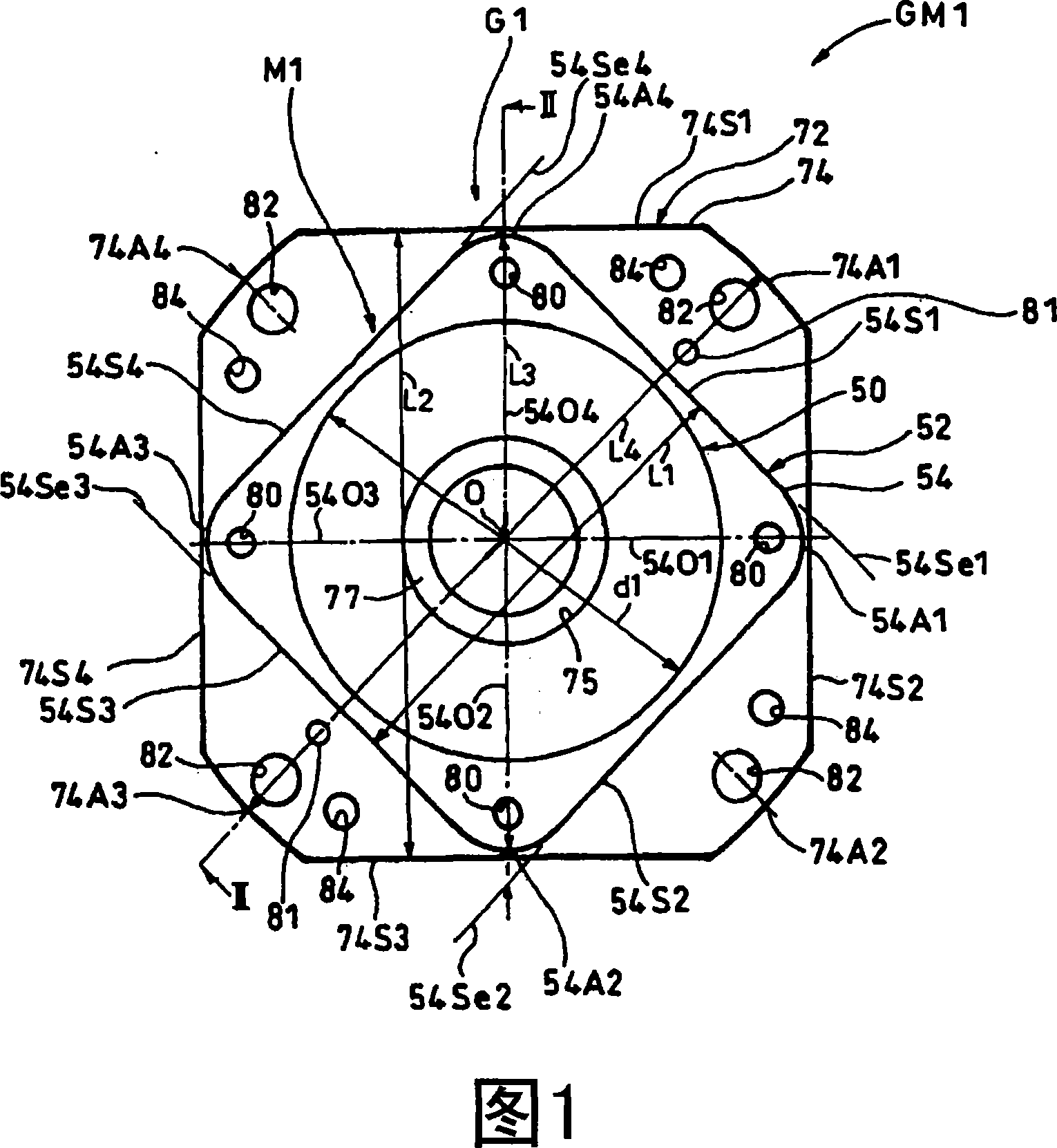

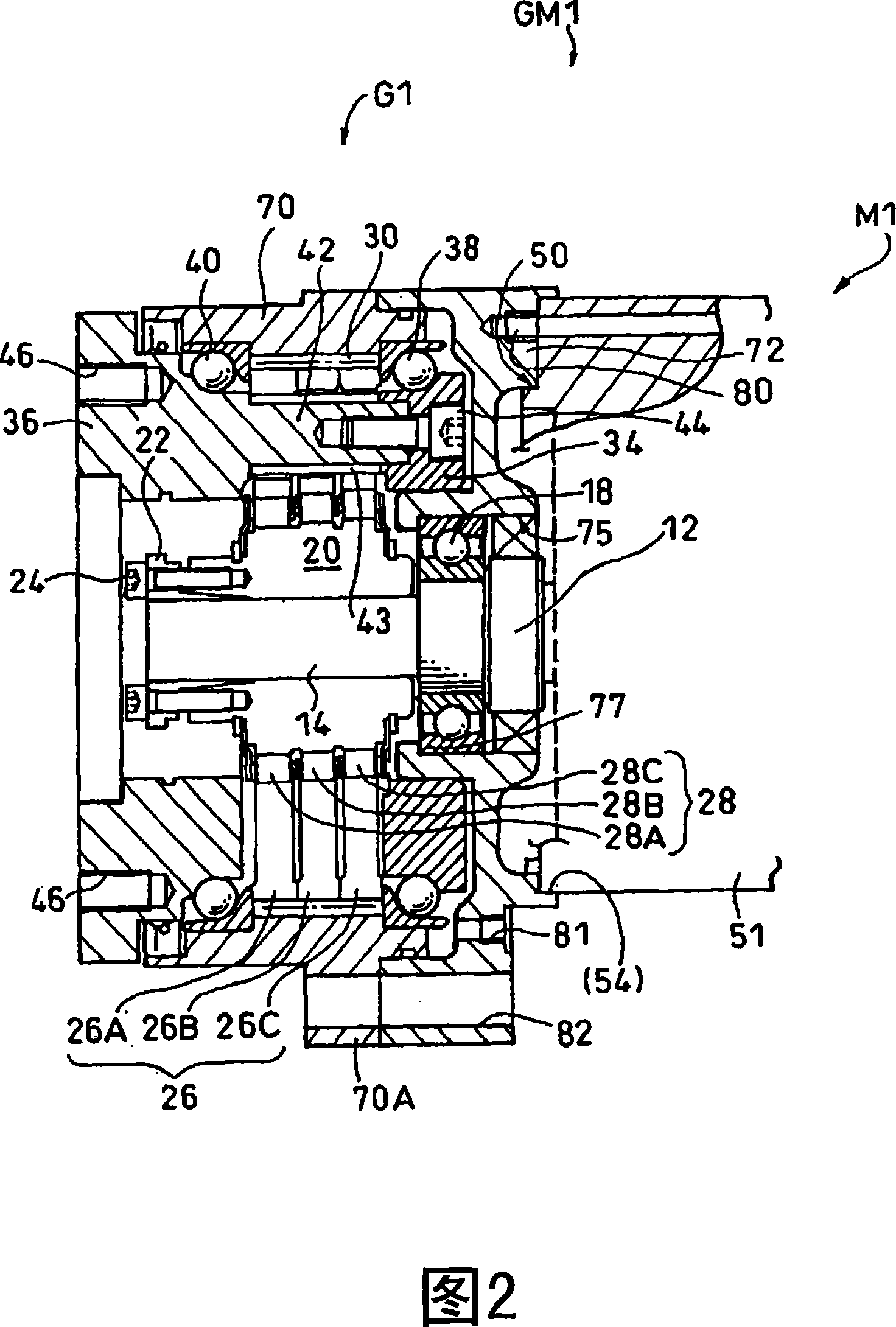

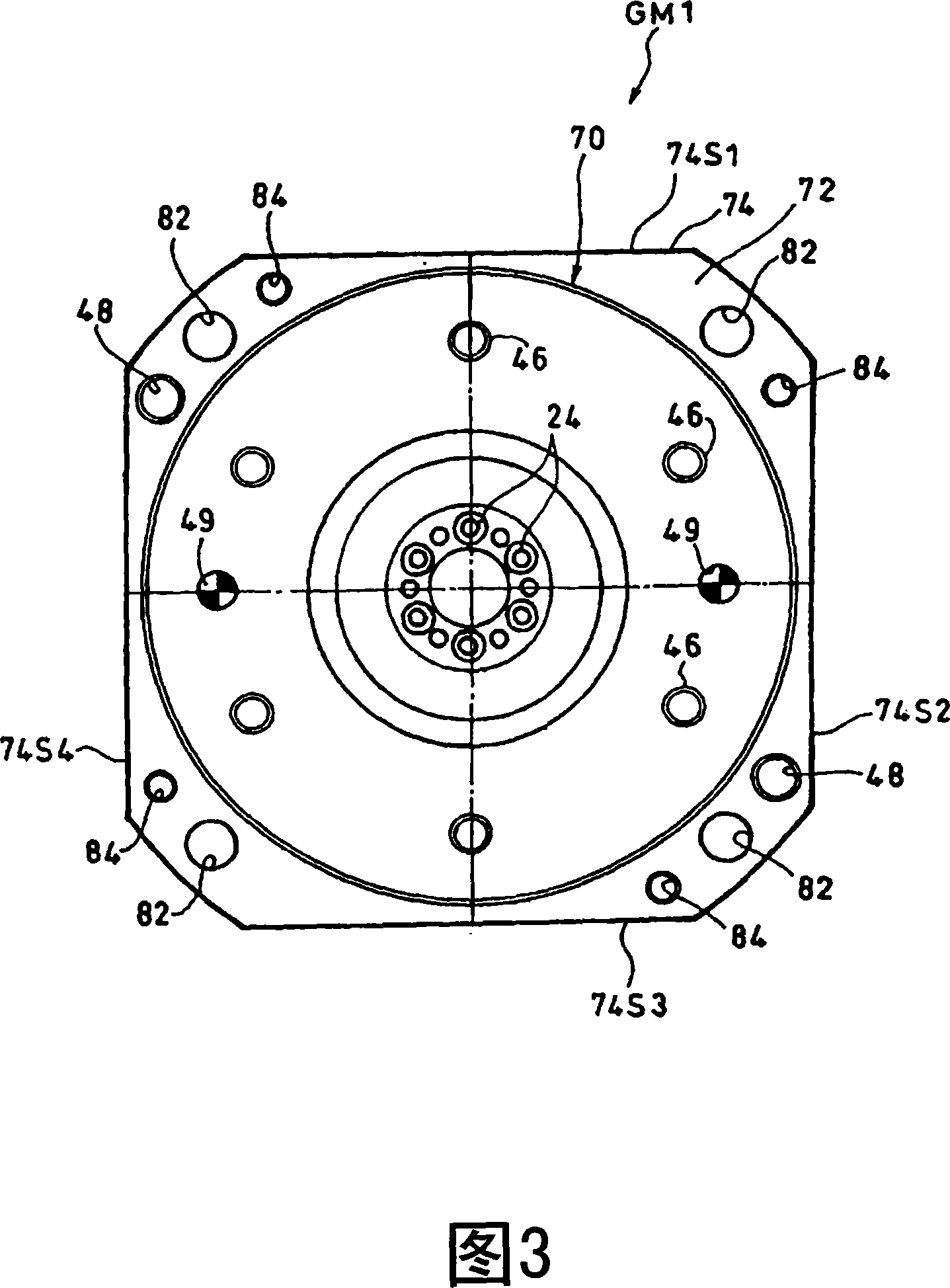

[0022] 1 to 3 show an example of a geared motor to which an embodiment of the present invention is applied.

[0023] This geared motor GM1 coaxially connects the motor M1 and the speed reducer G1, and is used for joint drive of an industrial robot (not shown). As shown in FIG. 2, the front-end|tip part of the motor shaft 12 of the motor M1 becomes the input shaft 14 of the speed reducer G1 directly. The housing main body 15 of the motor M1 does not close the parts on the reducer side (motor output side cover), and the reducer input side cover 72 (described later) also functions as an output side cover of the motor M1. A bearing 18 is assembled to a radially central portion of the reducer input side cover 72 , and the bearing 18 rotatably supports the motor shaft 12 (input shaft 14 ). In this embodiment, the reducer input side cover also functions as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com