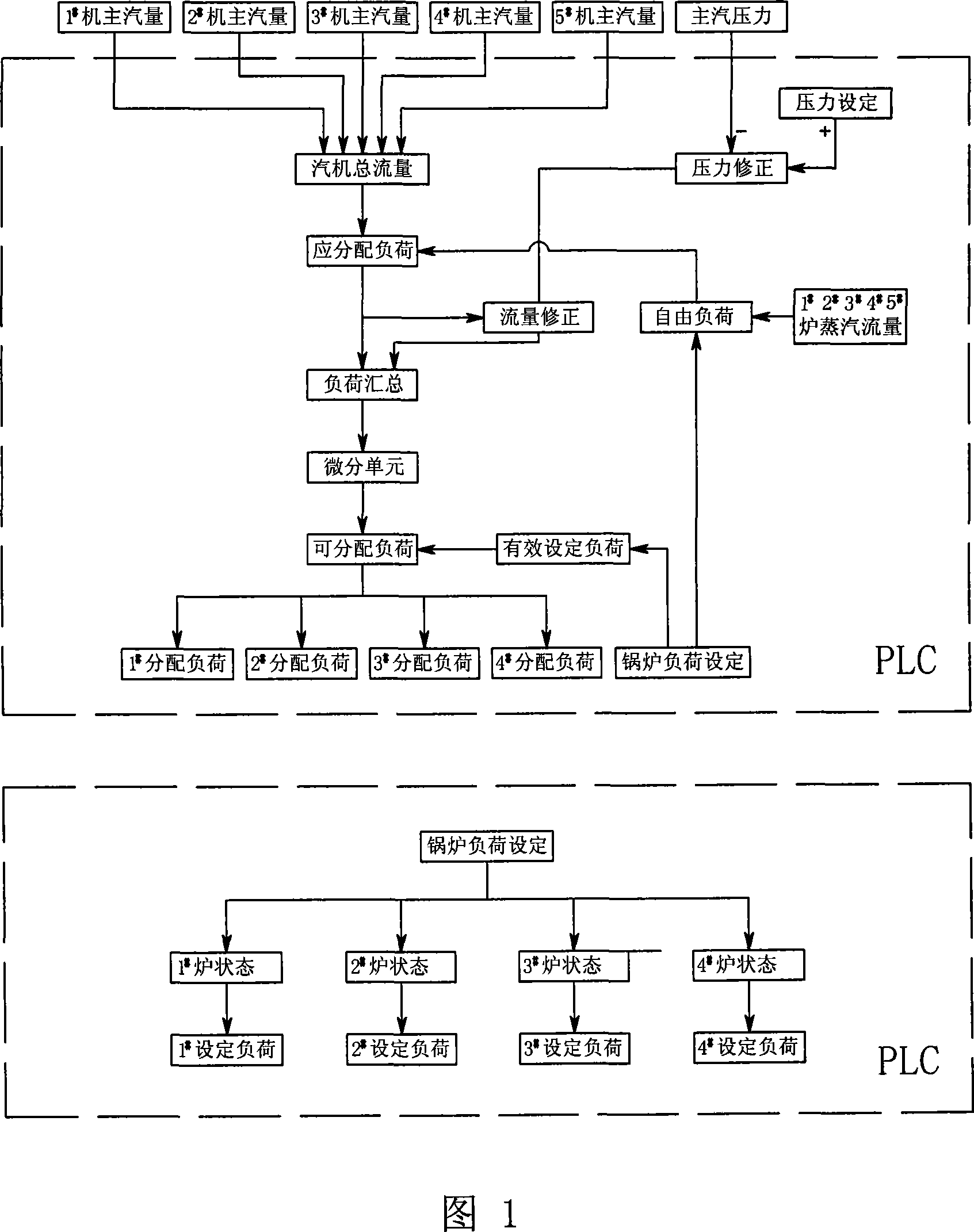

Distribution control method for automatic balancing pressures in mother pipes of boilers run parallelly

A technology of parent pipe pressure and automatic balance, applied in the field of boiler control, can solve the problems of threatening the operation safety of boilers and steam equipment, unstable pressure, large fluctuations, etc., and achieve the effect of automatic operation, stable operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Shunde Jinfang Group thermal power station in Shunde District, Foshan, has four 35T / h coal-fired boilers, one 6MW condensing unit, one 6MW back pressure unit, one 3MW back pressure unit, two 3MW condensing units , external power supply and steam supply, controlled by the method of the present invention, in this system, main pipe pressure=6MPa, #1 main steam flow rate=40T / h, #2 main steam flow rate=60T / h, #3 main steam flow rate =50T / h #5 Main steam flow = 100T / h, pressure setting = 3.58MPa, pressure correction PI: P = 35 I = 600, flow correction coefficient = 1.0. In actual operation, due to the automatic adjustment of the load distribution system with the change of load, the stability of the main pipe pressure is significantly improved compared with the conventional control method, and the load change of each boiler is also greatly improved than before. of stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com